Preparation method of small-size transition metal chalcogenide two-dimensional nanosheet

A transition metal chalcogenide, two-dimensional nanotechnology, applied in the direction of metal selenide/telluride, binary selenium/tellurium compound, molybdenum sulfide, etc., can solve the problems of large-scale production, large product size, harsh reaction conditions, etc. problems, to achieve the effect of large-scale production, smaller product size, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

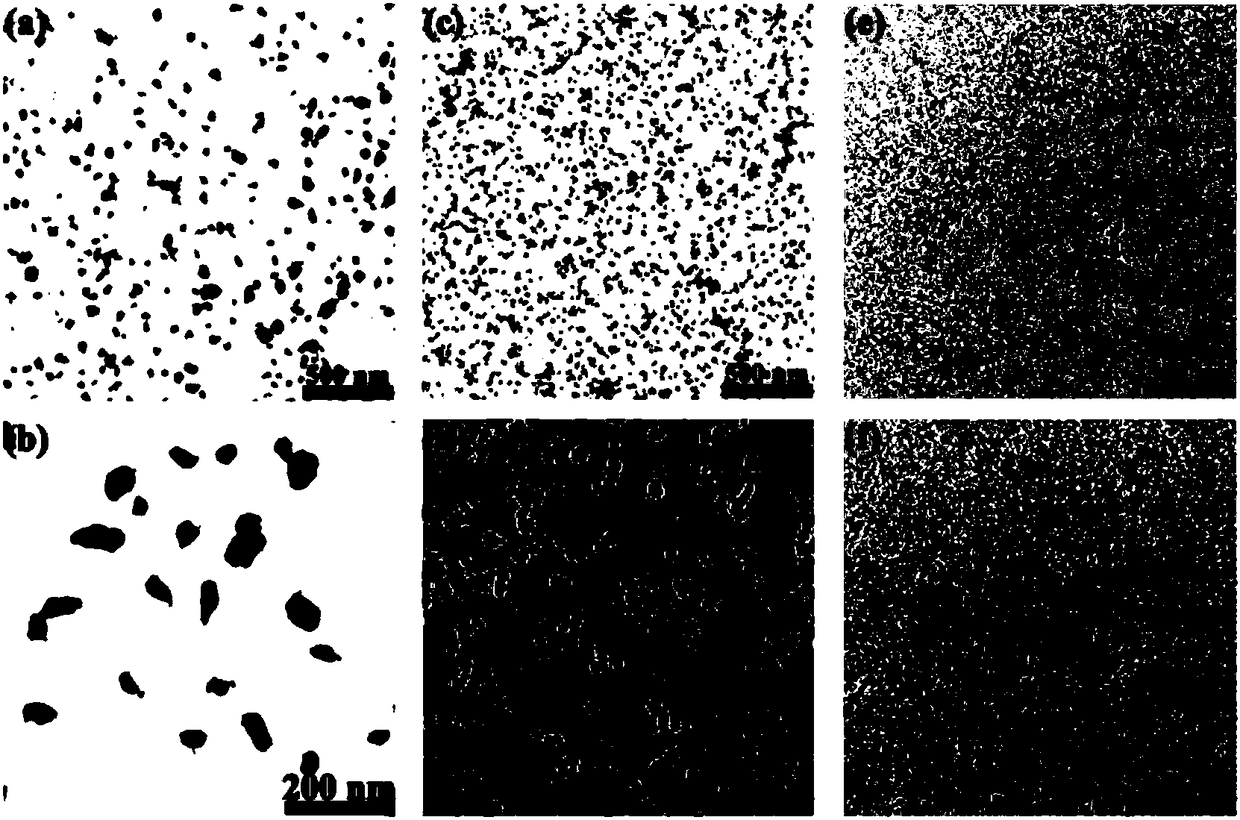

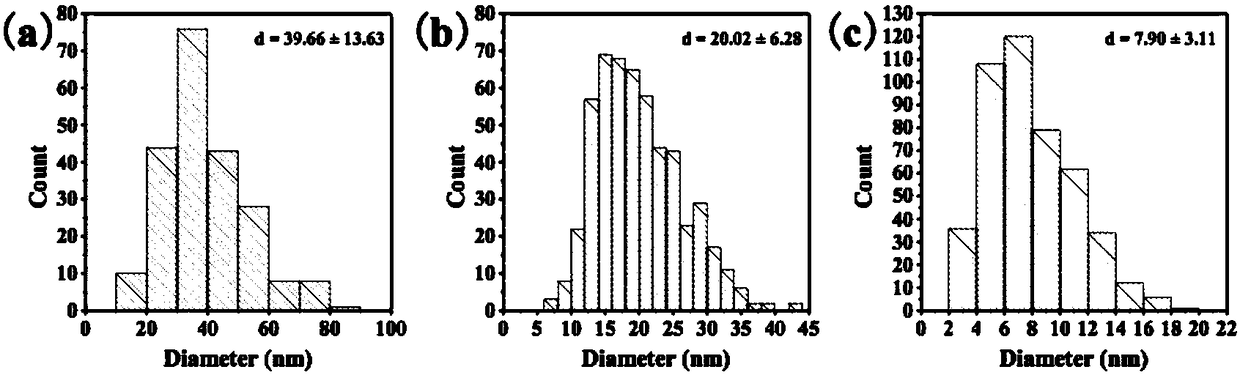

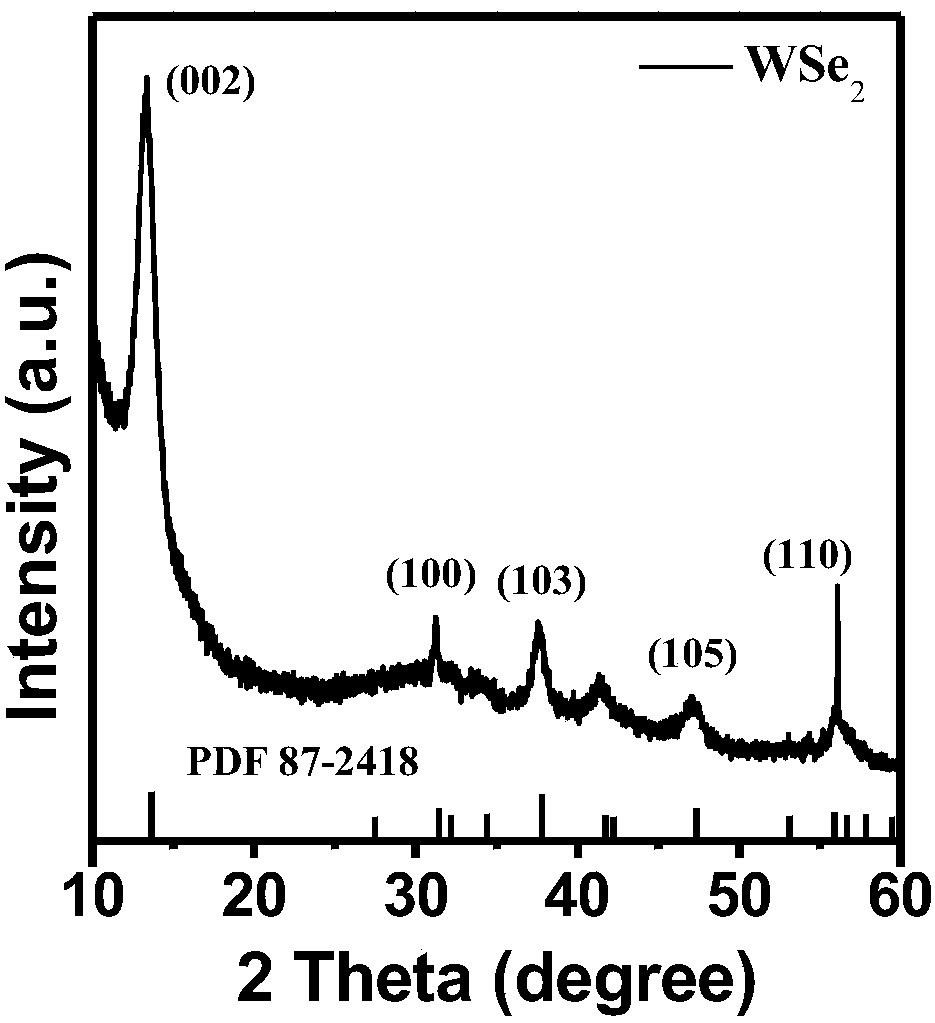

Embodiment 1

[0029] (a) Weighing of polymer and transition metal chalcogenide bulk powder

[0030] Weigh 1 g of sodium carboxymethylcellulose powder and 0.1 g of tungsten diselenide powder and add them to a dry stainless steel ball mill jar.

[0031] (b) Peel off by ball milling and mix with water to take out

[0032]Turn on the ball mill, set the total running time to 720 min, the forward and reverse interval time to 60 s, and the grinding speed to 650 rpm. After the grinding is finished, take out the ball mill jar, add 8 ml of ultrapure water, put it back into the ball mill, and run it at a grinding speed of 400 rpm for 15 minutes, then take out the solution, continue to add 8 ml of ultrapure water and repeat the above steps for a total of Five times, the solution was made up to 40 ml.

[0033] (c) Gradient centrifugation to obtain products of different sizes, and purify to remove excess polymers

[0034] Divide 40 ml of the solution obtained in step (b) into two 50 ml centrifuge tube...

Embodiment 2

[0036] (a) Weighing of polymer and transition metal chalcogenide bulk powder

[0037] Weigh 1 g of sodium carboxymethylcellulose powder and 0.1 g of molybdenum disulfide powder and add them to a dry stainless steel ball mill jar.

[0038] (b) Peel off by ball milling and mix with water to take out

[0039] Turn on the ball mill, set the total running time to 720 min, the forward and reverse interval time to 60 s, and the grinding speed to 650 rpm. After the grinding is finished, take out the ball mill jar, add 8 ml of ultrapure water, put it back into the ball mill, and run it at a grinding speed of 400 rpm for 15 minutes, then take out the solution, continue to add 8 ml of ultrapure water and repeat the above steps for a total of Five times, the solution was made up to 40 ml.

[0040] (c) Gradient centrifugation to obtain products of different sizes, and purify to remove excess polymers

[0041] Divide 40 ml of the solution obtained in step (b) into two 50 ml centrifuge tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com