A preparation method of up-conversion fluorescent anti-counterfeiting label

An anti-counterfeit label and fluorescent technology, which is applied in the field of preparation of up-conversion fluorescent anti-counterfeit labels, can solve the problems of high evaporation rate, nanoparticle agglomeration and precipitation, and uneven distribution of nanoparticles, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

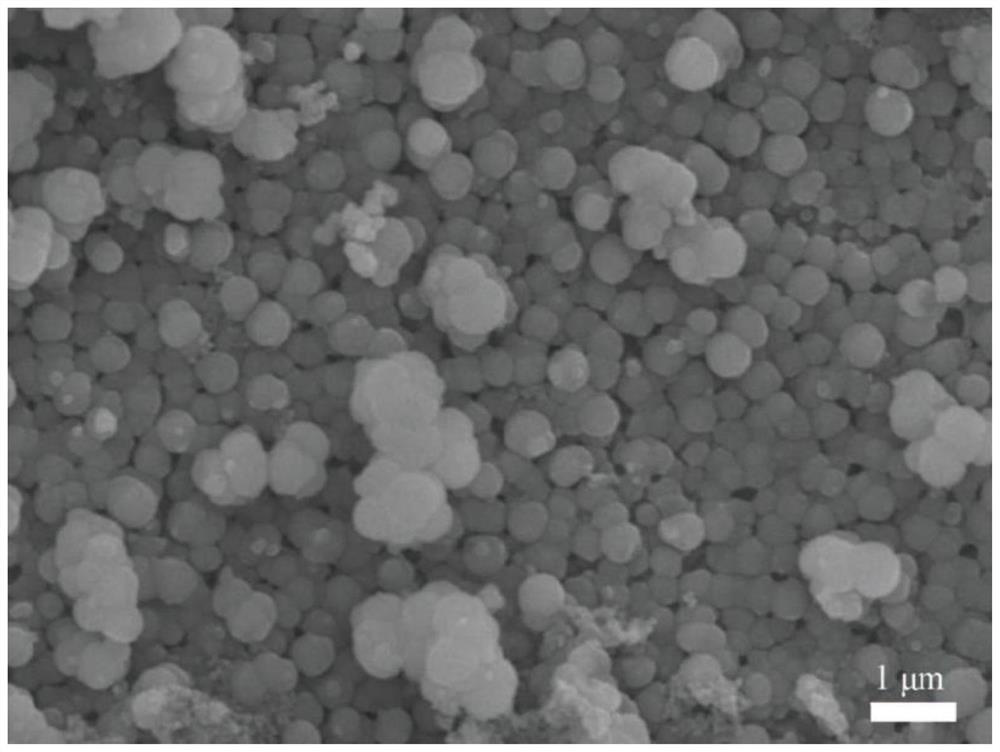

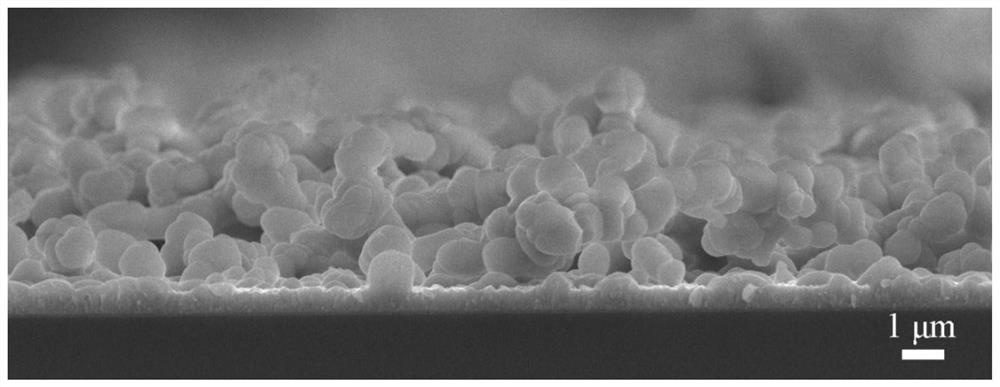

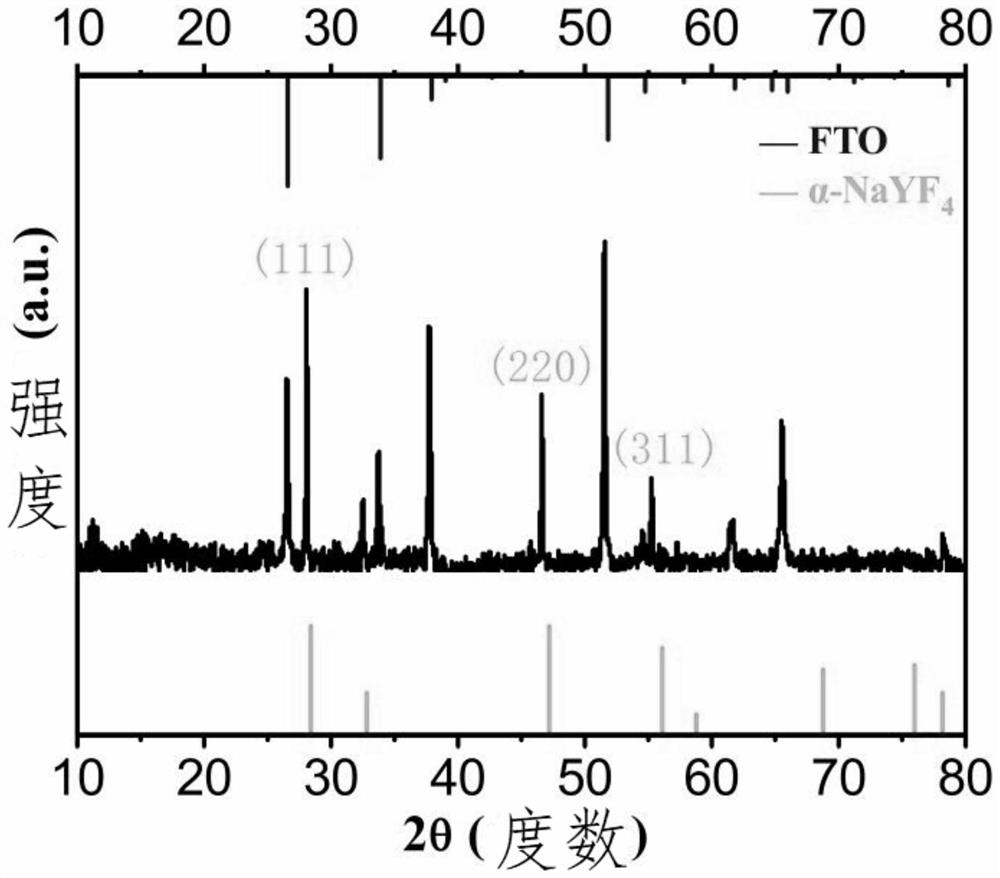

[0059] A method for preparing an up-conversion fluorescent anti-counterfeit label, the implementation steps are as follows:

[0060] (1) Plasma is used for conductive substrate (ITO or FTO) treatment: in the first step, the conductive substrate (FTO) is ultrasonically cleaned with deionized water, glass cleaner, alcohol and acetone, respectively. In the second step, use the plasma generator output voltage of 600-800V to activate nitrogen or argon under a vacuum condition of 100 Pa, and flush the surface of the conductive substrate (ITO or FTO) with the activated nitrogen or argon. ① Variable wettability: The wettability of the surface of some organic compounds has a great influence on the adhesion of pigments, inks, binders, etc., and on the electrical properties of the material surface such as flashover voltage and surface leakage current. The quantity that measures wettability is called the contact angle. ② Strong adhesion: after some polymers and metals are treated with pl...

Embodiment 2

[0070] A method for preparing an up-conversion fluorescent anti-counterfeit label, the implementation steps are as follows:

[0071] (1) Plasma for conductive substrate (flexible PET–ITO or flexible PI-ITO) treatment: In the first step, the conductive substrate (FTO) was ultrasonically cleaned with deionized water, glass cleaner, alcohol, and acetone, respectively . In the second step, use the plasma generator output voltage of 600-800V to activate nitrogen or argon under the vacuum condition of 100Pa, and flush the surface of the conductive substrate (flexible PET-ITO or flexible PI-ITO) with activated nitrogen or argon. Flexible PET-ITO or flexible PI-ITO is ITO sputtering on the surface of PET or PI to form a flexible conductive substrate.

[0072] (2) Patterned photoresist conductive substrate preparation (prepared by laser direct writing (LDW) technology), patterned photoresist is prepared on the conductive substrate: first set the homogenizer at a low speed of 500rpm fo...

Embodiment 3

[0079] A method for preparing an up-conversion fluorescent anti-counterfeit label, the implementation steps are as follows:

[0080] (1) Plasma is used for conductive substrate (ITO or FTO or PI-ITO) treatment: in the first step, the conductive substrate (ITO or FTO or PI-ITO) is treated with deionized water, glass cleaner, alcohol and acetone respectively. ) for ultrasonic cleaning. In the second step, use the plasma generator output voltage of 600-800V to activate nitrogen or argon under the vacuum condition of 100Pa, and flush the surface of the conductive substrate (ITO or FTO or PI-ITO) with activated nitrogen or argon.

[0081] (2) Preparation of patterned photoresist conductive substrate (preparation of patterned conductive substrate by ion beam etching): first set the homogenizer at a low speed of 500rpm for 6 seconds and at a high speed of 4000rpm for 30 seconds, the conductive substrate obtained in the S1 step Spin-coat polymethyl methacrylate (PMMA) e-beam resist u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com