Method for preparing color solar cell with pattern

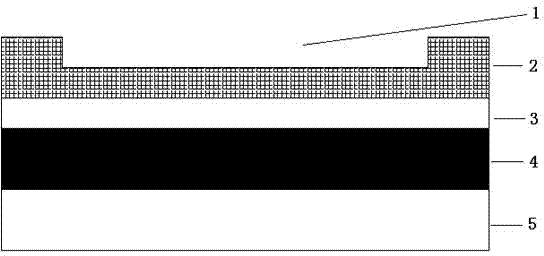

A technology for solar cells and patterns, applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems of immaturity, influence on the electrical properties of solar cells, and insufficient patterns, and achieve a simple manufacturing process, tight integration, and expansion. Effects in the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

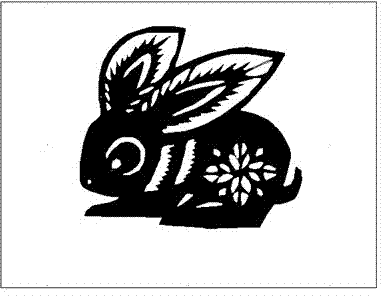

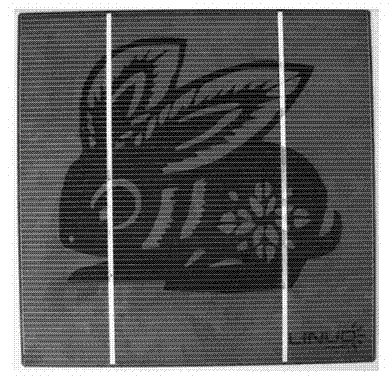

[0018] Example 1: Preparation of 156 polycrystalline silicon colored solar cells with a rabbit pattern.

[0019] First prepare a pattern with a rabbit pattern (such as figure 2 As shown) the screen; using screen printing technology, the Merck acid corrosion paste is printed on the color modulation layer of 156 polysilicon color solar cells; the solar cells printed with Merck acid corrosion paste will be completed at room temperature , placed for 15 minutes to complete the adjustment of the thickness of the color modulation layer; finally ultrasonically cleaned, sprayed with water on the positive electrode side with the pattern, and then dried to complete the production of the rabbit pattern of the color solar cell.

[0020] The above-mentioned obtained solar cells have electrical performance parameters of Efficiency: 16.3%; Pmmp: 3.94W; Isc: 8.046A; Voc: 0.626V; Impp: 7.545A; Compared with the sheet, its electrical performance parameters are basically not affected by pattern...

Embodiment 2

[0021] Example 2: Preparation of colored 125 single crystal solar cells with the word "POWER".

[0022] First prepare the screen plate with the pattern of "POWER", and use the method of screen printing to print Merck's acidic etching paste on the color modulation layer of the color 125 monocrystalline solar cell; the solar cell printed with the corrosive paste will be completed , placed at room temperature for 10 minutes to complete the adjustment of the thickness of the color modulation layer; finally ultrasonically cleaned, water sprayed on the positive electrode side with the pattern, and then dried to complete the production of the word "POWER" on the color solar cell.

[0023] The above-mentioned solar cells, Efficiency: 18.5%; Pmmp: 2.83W; Isc: 5.805A; Voc: 0.628V; Impp: 5.391A; Performance parameters are largely unaffected by patterning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com