Patterning preparation method for nano array

A nano-array and patterning technology is applied in the field of patterning preparation of nano-arrays, which can solve the problems of unsuitable nano-materials, harsh experimental conditions, and low requirements for substrates, and achieves improved field emission performance, simple operation, and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Using anhydrous AlCl 3 A patterned AlN nanocone array was fabricated using the precursor and Mo mesh as a mask.

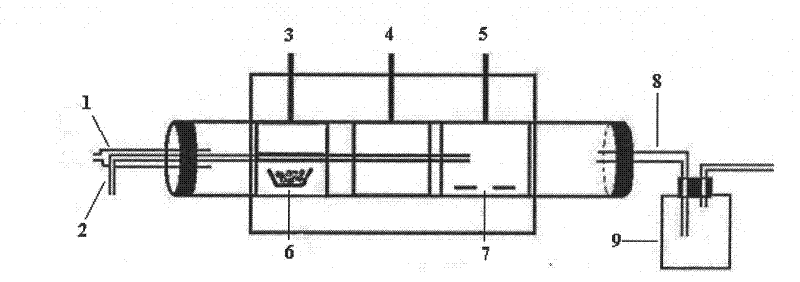

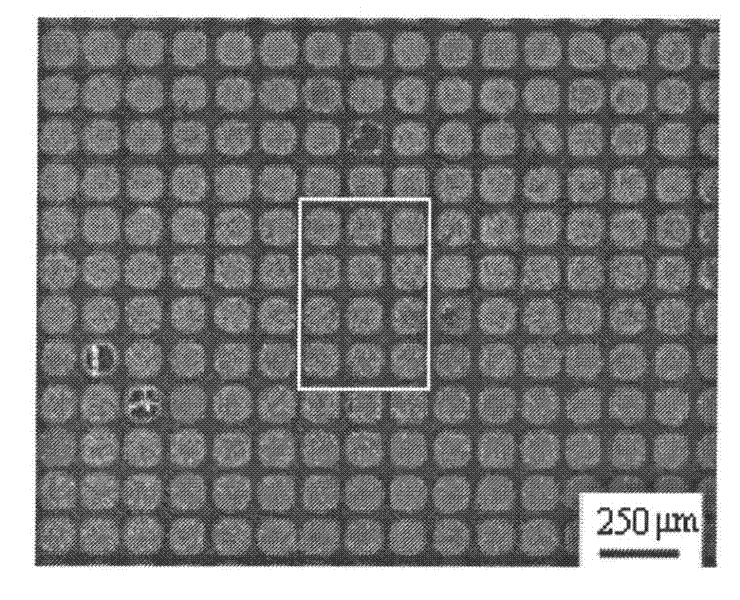

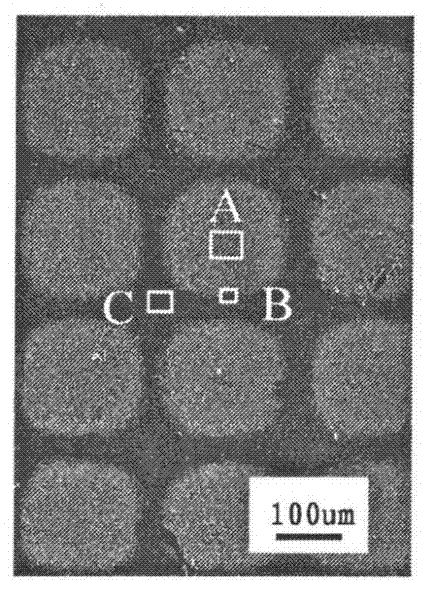

[0054] Anhydrous AlCl 3 Placed in a three-section tube temperature control furnace (such as figure 1 In the low-temperature reaction zone of ), the quartz tube with the Si wafer covered with 150 mesh Mo mesh is placed in the medium-temperature deposition zone, repeatedly filled with argon gas and evacuated by mechanical pump 2-3 times, under the protection of Ar gas (100sccm), At the same time, the temperature of the reaction chamber in the low temperature zone, the middle temperature zone and the high temperature zone are respectively increased to 130°C, 650°C, and 1100°C (the heating rate is 10°C / min). Then enter NH separately and at the same time 3 (20sccm) and Ar gas (300sccm), AlCl 3 After sublimation, it is transported to the deposition area and NH under the drive of Ar gas. 3 After mixing and reacting, the resulting AlN is deposited on the subst...

Embodiment 2

[0057] Example 2 Using anhydrous AlCl 3 A patterned AlN nanocone array was fabricated using the precursor and Mo mesh as a mask.

[0058] Anhydrous AlCl 3 Placed in the low-temperature reaction zone of a three-stage tubular temperature-controlled furnace, placed a quartz tube covered with a 150-mesh Mo mesh in the deposition zone at a medium temperature, repeatedly filled with argon gas and evacuated 2-3 times with a mechanical pump. Under the protection of air (100sccm), the temperature of the reaction chamber in the low temperature zone, middle temperature zone and high temperature zone was raised to 140℃, 780℃, 1100℃ (heating rate is 10℃ / min). Then enter NH separately and at the same time 3 (20sccm) and Ar gas (300sccm), AlCl 3 After sublimation, it is transported to the deposition area and NH under the drive of Ar gas. 3 After mixing and reacting, the resulting AlN is deposited on the substrate. The reaction lasts for 4 hours, and is naturally cooled to room temperature under...

Embodiment 3

[0059] Example 3 A patterned AlN nanocone was prepared using Al powder as a precursor.

[0060] Place Al in the high temperature reaction zone of a tubular temperature control furnace, place the Si substrate covered with Mo mesh on the Al powder 0.5-5cm above the Al powder, repeatedly fill with argon and evacuated with a mechanical pump 2-3 times, in Ar gas ( Under the protection of 100sccm), the temperature of the reaction chamber in the high temperature zone was increased to 1100°C (the temperature rise rate was 10°C / min). Then pass into NH 3 / N 2 (200sccm) and Ar gas (300sccm), Al and NH 3 / N 2 The reaction produces AlN. The reaction lasts for 4 hours, and is naturally cooled to room temperature under the protection of Ar gas (100sccm), and the Mo mesh is stripped to obtain patterned AlN nanomaterials, such as Figure 14-16 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com