Method for preparing high-throughput covalent organic framework nano-filtration membrane on basis of interfacial polymerization

A covalent organic framework and interfacial polymerization technology, applied in the field of porous materials and separation membranes, can solve the problems of low flux, easy detachment, and difficult scale-up preparation of COF composite membranes, so as to promote large-scale preparation, increase permeation flux, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

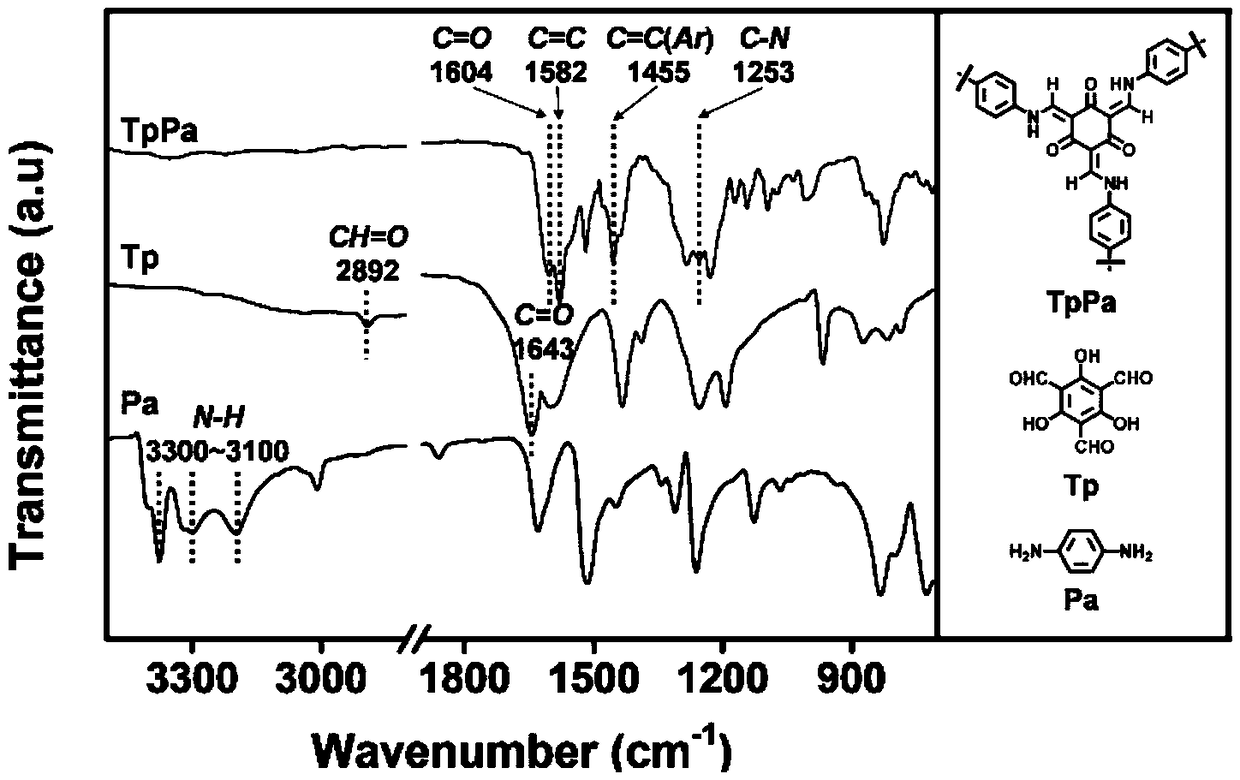

[0051] 1) Weigh 2.04g of p-phenylenediamine (p-phenylenediamine, Pa) and dissolve it in 100 mL of deionized water to prepare a p-phenylenediamine aqueous phase solution with a mass fraction of 1.00 wt.%. Subsequently, 1.00 mL of glacial acetic acid with a mass fraction of 98 wt.% was added as a catalyst, and the mass fraction of acetic acid in the aqueous phase solution was 1.01 wt.%. Another 0.0330g 1,3,5-triformylphloroglucinol (1,3,5-triformylphloroglucinol, Tp) was weighed and dissolved in 100mL of n-hexane to prepare 1,3,5- Triformylphloroglucinol oil phase solution.

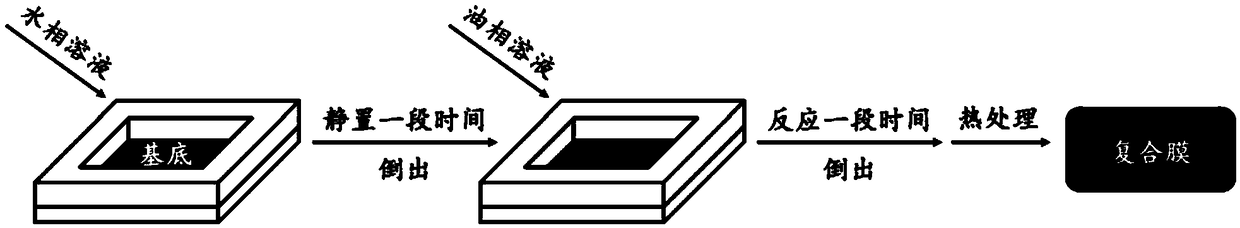

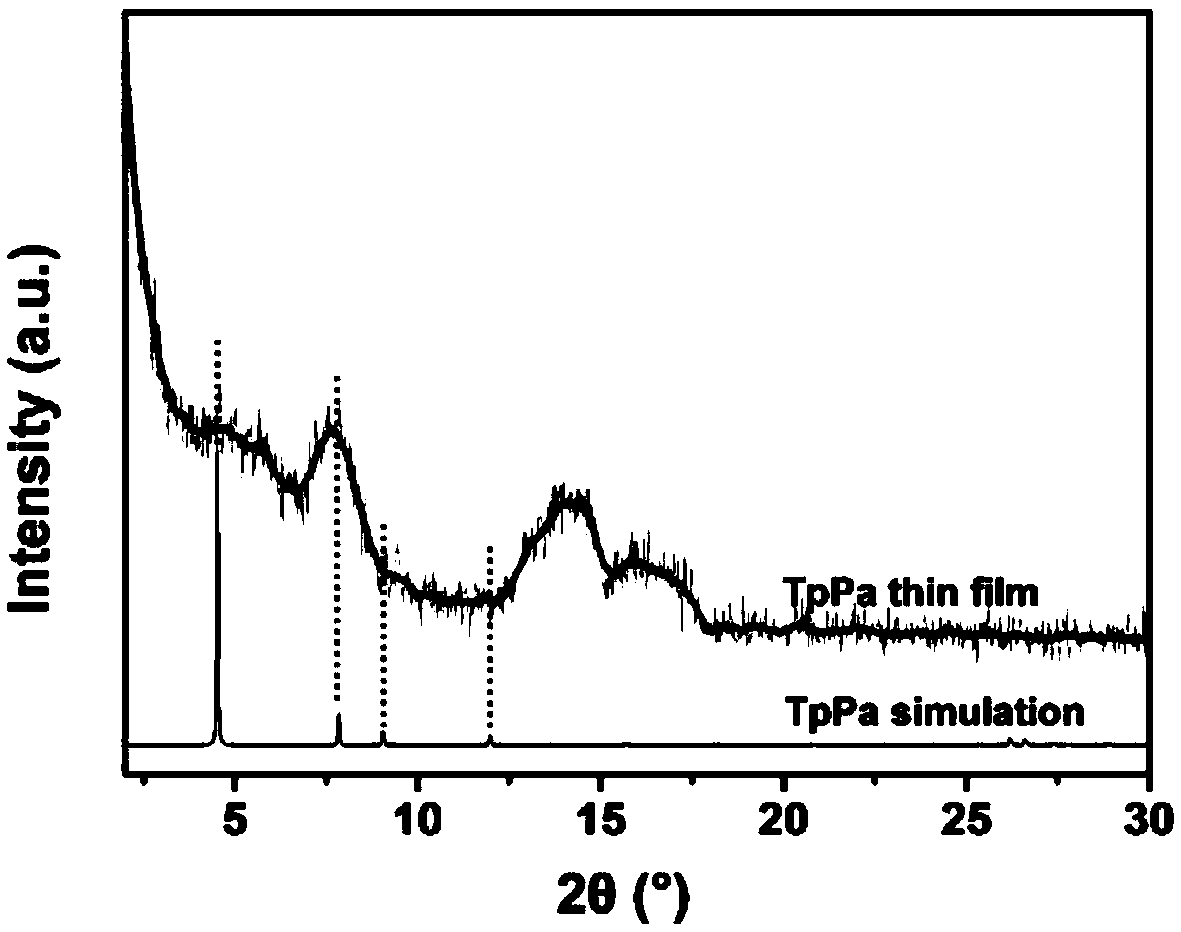

[0052] 2) The simple interfacial polymerization process such as figure 1 shown. Its steps are as follows: Polysulfone (PSF) ultrafiltration membrane base (pure water flux: 352L / (h·m 2 bar), the rejection rate of bovine serum albumin (BSA): 44%) is fixed in the membrane module that can store and discharge liquid, and remove the residual moisture on the surface of the porous carrier. Pour 20mL of the aque...

Embodiment 2

[0059] 1) Weigh 4.17g of p-phenylenediamine (p-phenylenediamine, Pa) and dissolve it in 100mL of deionized water to prepare a p-phenylenediamine aqueous phase solution with a mass fraction of 4.00wt.%. Subsequently, 14.67 g of p-toluenesulfonic acid monohydrate was added as a catalyst, and the mass fraction of p-toluenesulfonic acid in the aqueous phase solution was 11.18 wt.%. Another weighed 0.1990g of 1,3,5-triformylbenzene (1,3,5-triformylbenzene, TFB) was dissolved in 100mL of dichloromethane to prepare 1,3,5-triformylbenzene with a mass fraction of 0.15wt.%. Benzene oil phase solution.

[0060] 2) An anodic aluminum oxide (AAO) membrane with a pore size of 100 nm was selected as the porous substrate, and the reaction time was 60 s. Other operations were the same as step 2) in Example 1. Finally, a separation layer of COF-LZU1 (an imine covalent organic framework with a theoretical pore size of 1.8 nm) was formed on the alumina substrate after hydrolysis.

[0061] 3) Th...

Embodiment 3

[0065] 1) Weigh 4.08g of benzidine (BD) and dissolve it in a mixed solvent of 90mL of deionized water and 10mL of acetonitrile to prepare an aqueous solution of benzidine with a mass fraction of 4.00wt.%. Subsequently, 3.00 mL of hydrochloric acid with a mass fraction of 37 wt.% was added thereto as a catalyst, and the mass fraction of hydrochloric acid in the aqueous phase solution was 1.29 wt.%. Another weighed 0.1731g of 1,3,5-triformylphloroglucinol (1,3,5-triformylphloroglucinol, Tp) was dissolved in 100mL of mesitylene to prepare 1,3,5 - Triformylphloroglucinol oil phase solution.

[0066] 2) A polyvinylidene fluoride microfiltration membrane is selected as the porous substrate, the water phase contact time is 60 s, the reaction time is 90 s, and other operations are the same as step 2) in Example 1. Finally, a separation layer of TpBD (an imine covalent organic framework with a theoretical pore size of 2.3 nm) was formed on the polyvinylidene fluoride microfiltration m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com