Waterproof UV snowflake printing ink and preparation method thereof

A snowflake ink, water-resistant technology, applied in inks, household appliances, applications, etc., can solve the problems of ordinary UV snowflake ink adhesion drop, coating peeling, easy moisture absorption and moisture absorption of paper substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

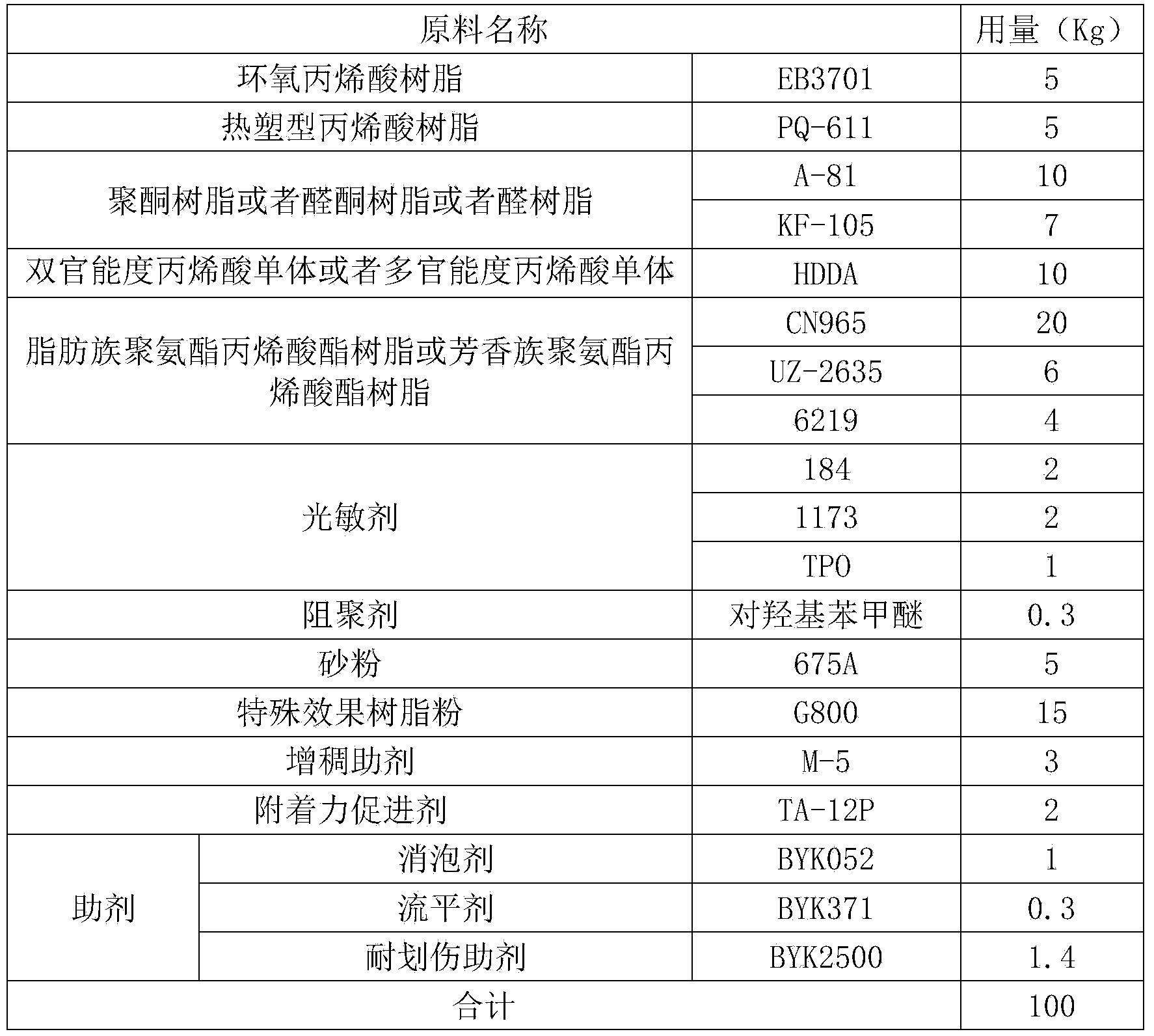

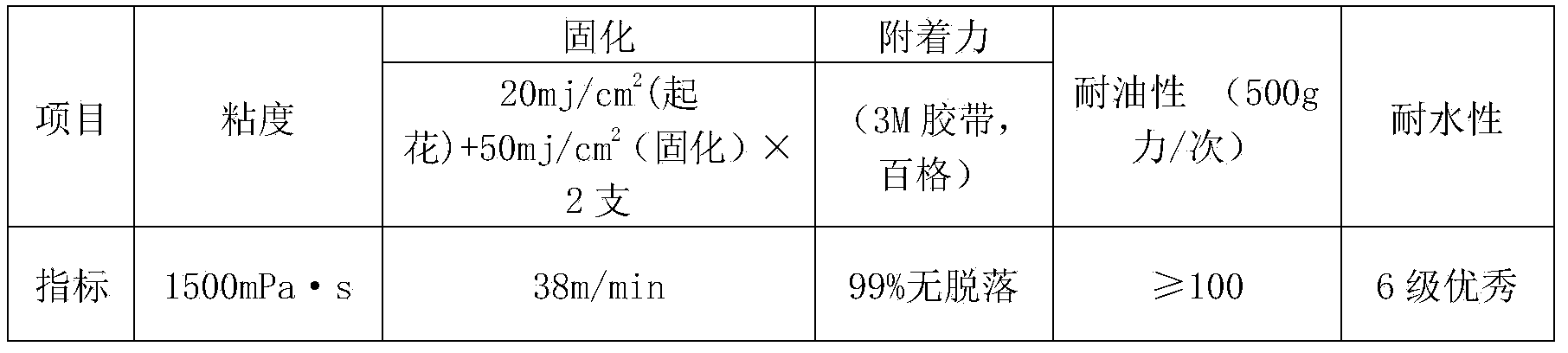

[0053] The types and parts by weight of the selected raw materials are as follows:

[0054]

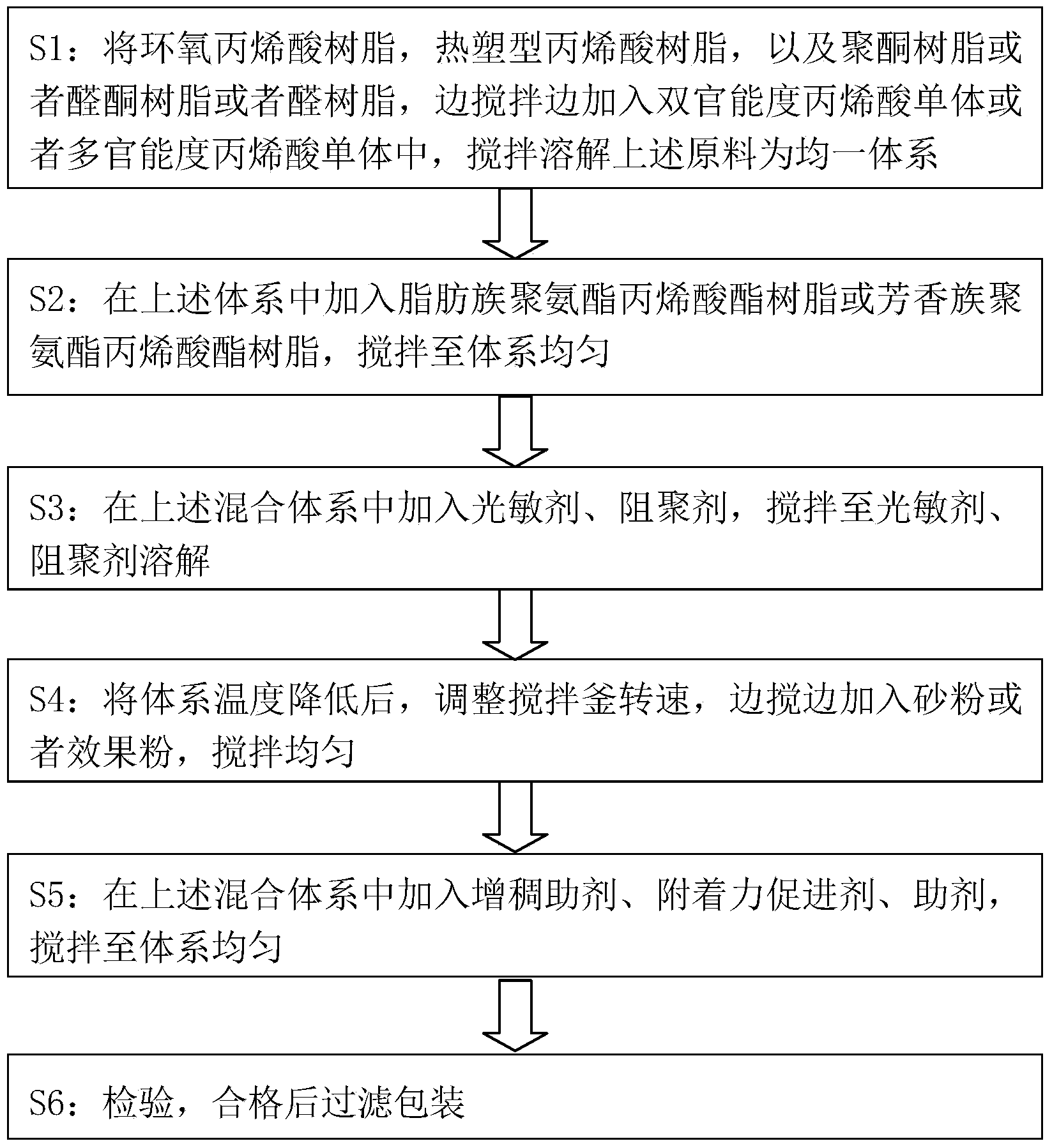

[0055] Select above-mentioned formula to carry out the process of preparing printing ink as follows:

[0056] 1. Stir epoxy acrylic resin EB3701, thermoplastic acrylic resin PQ-611, polyketone resin or aldehyde ketone resin or aldehyde resin A-81, KF-105, and difunctional acrylic monomer HDDA evenly, dissolve as homogeneous system;

[0057] 2. Add aliphatic urethane acrylate resin or aromatic urethane acrylate resin CN965, UZ-2635, 6219 to the above system and stir evenly;

[0058] 3. Add photosensitizers 184, 1173, TPO, polymerization inhibitor p-hydroxyanisole into the above mixing system, and stir until dissolved;

[0059] 4. After cooling down, add sand powder and effect powder 675A, G800 while stirring at low speed, and stir evenly;

[0060] 5. Add thickening aid M-5, adhesion promoter TA-12P, defoamer BYK052, leveling agent BYK371, scratch resistance additive BYK2500 into ...

specific Embodiment 2

[0064] The types and parts by weight of the selected raw materials are as follows:

[0065]

[0066] Select above-mentioned formula to carry out the process of preparing printing ink as follows:

[0067] 1. Stir epoxy acrylic resin CN2204, thermoplastic acrylic resin B-66, aldehyde and ketone resin CA, and multifunctional acrylic monomers TMPTA and TPGDA evenly to dissolve into a homogeneous system;

[0068] 2. Add aliphatic urethane acrylate resin or aromatic urethane acrylate resin EB270, 611B85, PU-210 into the above system, and stir evenly;

[0069] 3. Add photosensitizers 1046, 3250, TPO-L, polymerization inhibitor ST-1 into the above mixing system, and stir until dissolved;

[0070] 4. After cooling down, add sand powder 3620 and effect powder C800, 9604 while stirring at low speed, and stir evenly;

[0071] 5. Add thickening aid OK520, adhesion promoter TAA, defoamer KS-66, leveling agent BYK307, scratch resistance additive BYK3501 into the above mixing system, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com