Nylon/polyketone alloy material and preparation method thereof

An alloy material, nylon technology, applied in the field of nylon/polyketone alloy material and its preparation, can solve the problems of affecting dimensional stability, inferior strength and rigidity, low friction coefficient, etc., to improve thermal stability, increase surface hardness, The effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of described nylon / polyketone alloy material comprises the following steps:

[0026] 1) Accurately weigh the components of the formula, mix nylon and polyketone resin uniformly to obtain component A, and mix compatibilizer, lubricant, antioxidant, stabilizer and nucleating agent uniformly to obtain component B ; Glass fiber addition via side feed;

[0027] 2) Add component A and component B into a twin-screw extruder in different regions at the same time for extrusion, water cooling and pelletizing to obtain a nylon / polyketone alloy material with excellent performance.

[0028] Among them, the temperature of the twin-screw extruder from the feed section to the machine head is as follows: the temperature of the first zone is 160°C-180°C, the temperature of the second zone is 230°C-250°C, the temperature of the third zone is 230°C-250°C, and the temperature of the fourth zone is 210°C. ℃-230℃, the temperature of the fifth zone is 210℃-230℃, the tem...

Embodiment 1-3

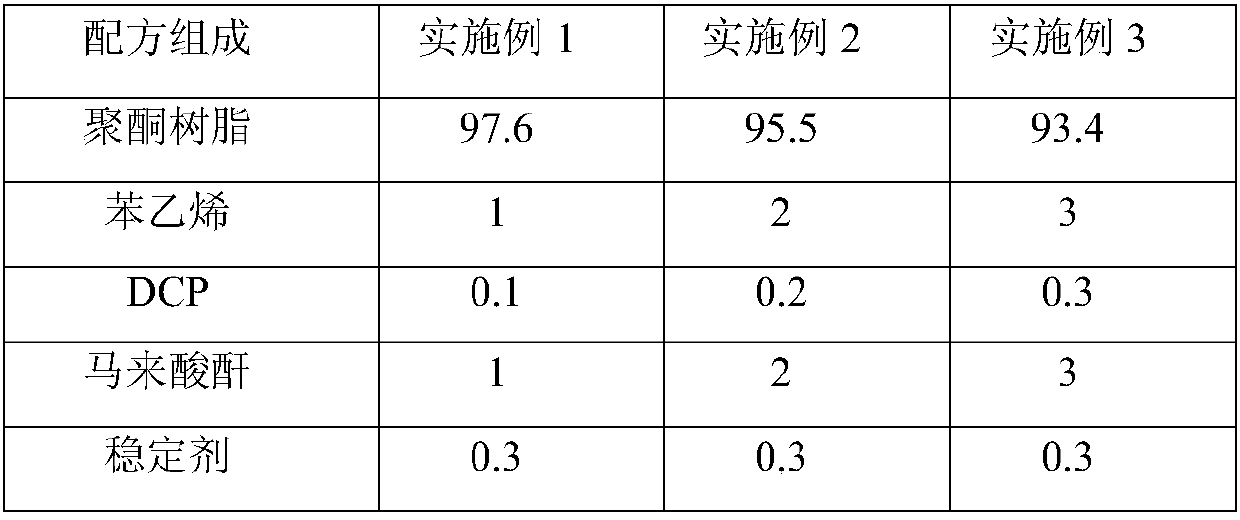

[0042]Prepare compatibilizer maleic anhydride grafted polyketone, its composition proportioning by weight is:

[0043]

[0044]

[0045] The preparation method of this compatibilizer comprises steps:

[0046] (1) take each component by weight proportioning;

[0047] (2) Dissolve the maleic anhydride in the components weighed in step (1) in the middle of the comonomer, then place the polyketone, initiator and stabilizer in a high mixer and stir for 5 -10 minutes;

[0048] (3) Place the mixture obtained in step (2) in a twin-screw machine, melt and extrude, and granulate. 180-200°C, the temperature of the fourth zone is 160-180°C, the temperature of the fifth zone is 160-180°C, the temperature of the die head is 190-210°C, the residence time of the cylinder is 1-3 minutes, and the melt pressure is 10-20MPa.

[0049] Through the above steps, the maleic anhydride grafted polyketone compatibilizer is finally obtained, and the grafting rate of Example 2 is the highest.

Embodiment 4-8

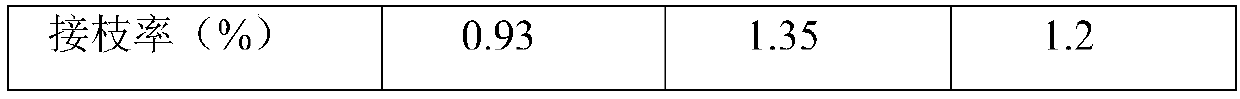

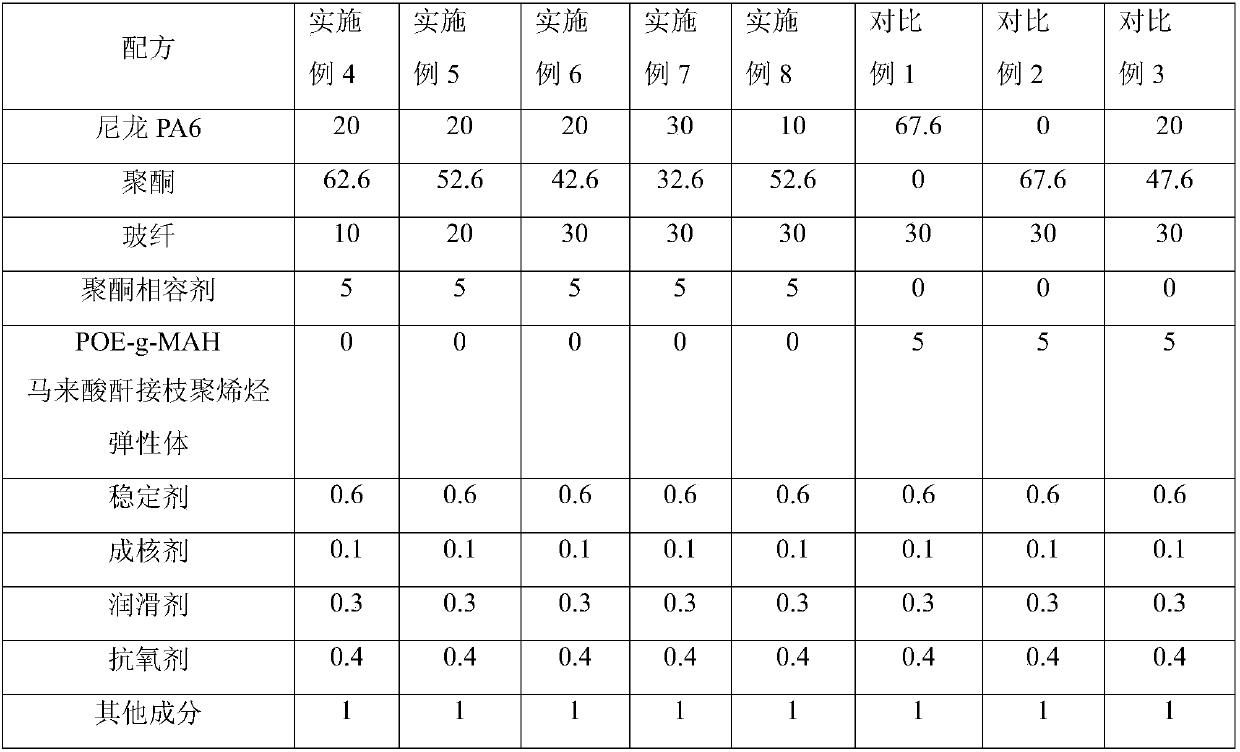

[0051] The compatibilizer that embodiment 2 obtains is used for the preparation of nylon and polyketone alloy material, specifically as follows:

[0052]

[0053] Performance testing and evaluation:

[0054] The particle materials prepared in the above-mentioned Examples 4-8 and Comparative Examples 1-3 were first dried in a blast oven at 100-120° C. for 4 hours, and then the dried particle materials were made into standard test specimens with an injection molding machine test.

[0055] Wherein, the tensile strength is tested according to the ASTM D-638 standard. The sample type is type I, the spline size (mm): (176±2) (length)×(12.6±0.2) (end width)×(3.05±0.2) (thickness), and the tensile speed is 50mm / min ;

[0056] The notched impact strength is tested according to ASTM D-256 standard. The sample type is type I, and the sample size (mm): (63±2)×(12.45±0.2)×(3.1±0.2); the notch type is type A, and the remaining thickness of the notch is 1.9mm;

[0057] Corrosion resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com