High-impact halogen-free flame-retardant POK/PA (polyketone/polyamide) alloy material

An alloy material and high-impact technology, applied in the field of high-impact halogen-free flame-retardant POK/PA alloy materials, can solve the problems of halogen-free flame-retardant and achieve high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

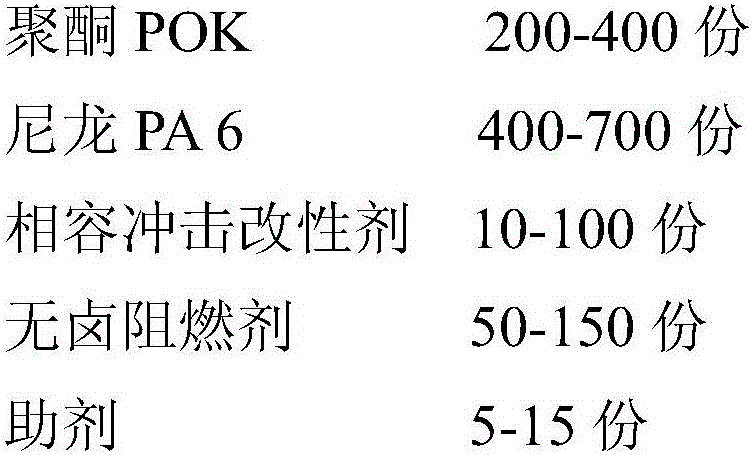

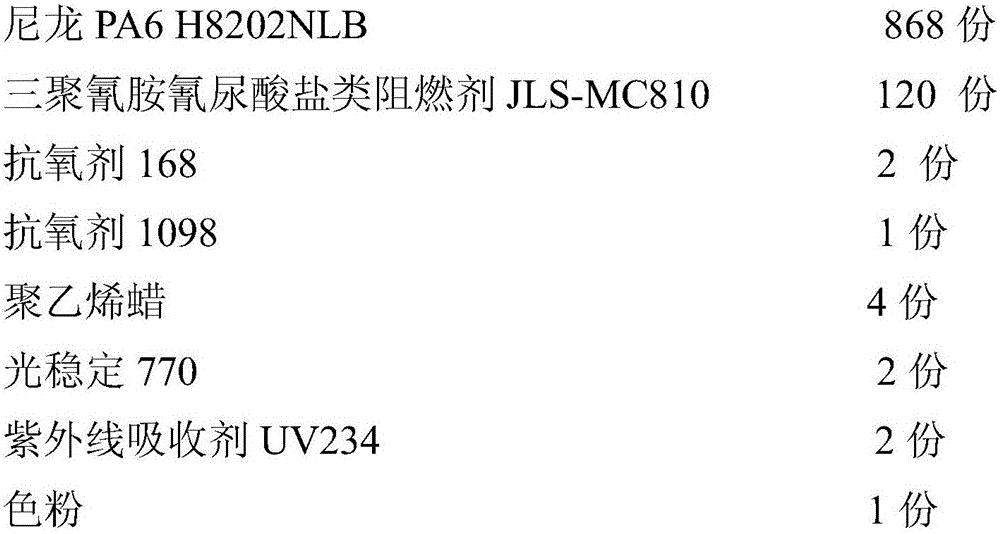

[0036] The following components in parts by weight:

[0037]

[0038] Mix the above-mentioned raw material components in a high-speed mixer for 3-5 minutes, then extrude through a twin-screw extruder at 220-240°C, cool, and granulate. Injection molded into standard splines at 260°C.

Embodiment 2-6

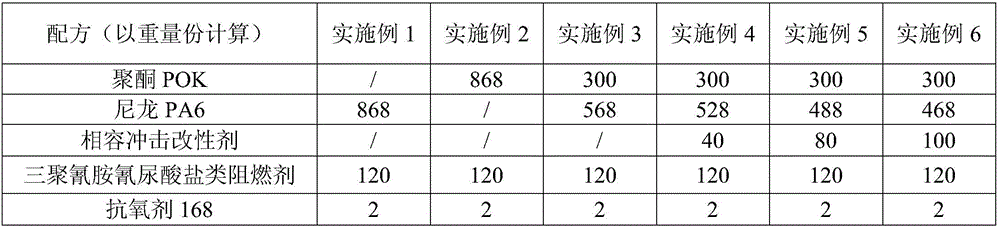

[0040] The raw materials were weighed according to the parts by weight in Table 1, and the preparation method was the same as in Example 1.

[0041] Components and proportioning of table 1 embodiment 1-6

[0042]

[0043]

[0044] Evaluation of Implementation Effect

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com