Alcohol-soluble polyamide gravure plastic surface printing ink

A technology of alcohol-soluble polyamide and plastic watch, which is applied in the field of printing ink, which can solve the problems of benzene solvent emission, damage to human health, and destruction of the ozone layer, and achieve good low temperature resistance, anti-adhesion, and good solvent release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

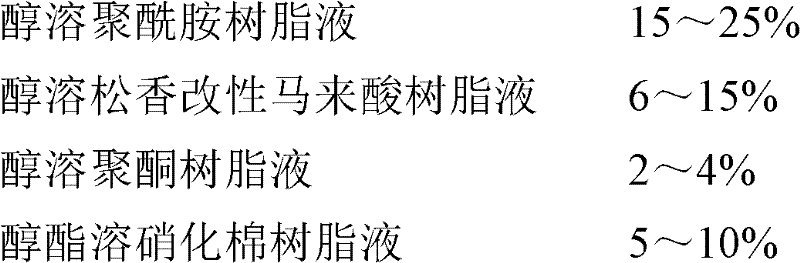

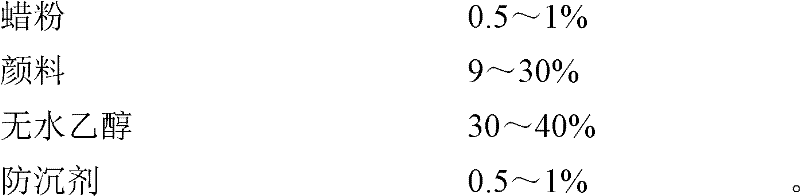

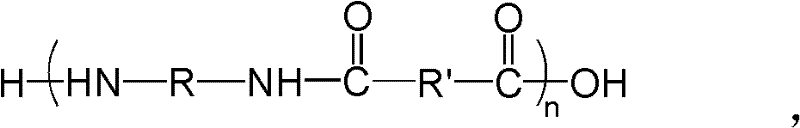

[0028] The alcohol-soluble polyamide gravure plastic surface printing white ink provided in this embodiment is made by mixing the following components in weight percentage:

[0029]

[0030] The preparation process of the alcohol-soluble polyamide gravure plastic surface printing white ink provided in this embodiment is as follows: alcohol-soluble polyamide resin liquid, alcohol-soluble rosin modified maleic acid resin liquid, alcohol-soluble polyketone resin liquid, alcohol-ester-soluble nitrocellulose resin Liquid, 3620 wax powder, titanium dioxide, and fumed silica were put into a disperser and stirred for 40 minutes, and the mixture obtained by stirring was put into a sand mill to grind and disperse 4 times, 60 minutes each time, and the fineness of the ground material was not greater than 15um. It is best to add absolute ethanol, and then use a disperser to stir and disperse for 30 minutes to prepare the alcohol-soluble polyamide gravure plastic surface printing white i...

Embodiment 2

[0032] The alcohol-soluble polyamide gravure plastic surface printing red ink provided in this embodiment is made by mixing the following components in percentage by weight:

[0033]

[0034] The preparation process of the alcohol-soluble polyamide gravure plastic surface printing red ink provided in this embodiment is as follows: alcohol-soluble polyamide resin liquid, alcohol-soluble rosin modified maleic acid resin liquid, alcohol-soluble polyketone resin liquid, alcohol-ester-soluble nitrocellulose Put the resin liquid, 3620 wax powder, red organic pigment, and gas phase silica into the disperser and stir for 40 minutes, put the stirred mixture into the sand mill to grind and disperse 6 times, each time for 80 minutes, and the fineness of the ground material is not greater than 15um , it is best to add absolute ethanol, and then use a disperser to stir and disperse for 30 minutes to prepare the alcohol-soluble polyamide gravure plastic surface printing red ink provided i...

Embodiment 3

[0036] The alcohol-soluble polyamide gravure plastic surface printing black ink provided in this embodiment is made by mixing the following components in weight percentage:

[0037]

[0038]

[0039] The preparation process of the alcohol-soluble polyamide gravure plastic surface printing black ink provided in this embodiment is as follows: alcohol-soluble polyamide resin liquid, alcohol-soluble rosin modified maleic acid resin liquid, alcohol-soluble polyketone resin liquid, alcohol-ester-soluble nitrocellulose Put the resin liquid, 3620 wax powder, red organic pigment, and fumed silica into the disperser and stir for 60 minutes, put the mixture obtained by stirring into the sand mill to grind and disperse 7 times, each time for 80 minutes, and the fineness of the ground material is not greater than 12um , it is best to add absolute ethanol, and then use a disperser to stir and disperse for 40 minutes to prepare the alcohol-soluble polyamide gravure plastic surface print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com