Modified polyurethane resin and benzene-free and ketone-free composite plastic ink containing same, as well as preparation methods thereof

A polyurethane resin and polyurethane technology, applied in the field of modified polyurethane resin and its preparation, can solve the problems of development and promotion of bound chloropropane ink, unstable chlorine atom, difficult application, etc., and achieve good safety and health, bright and stable color. , the effect of prolonging the storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

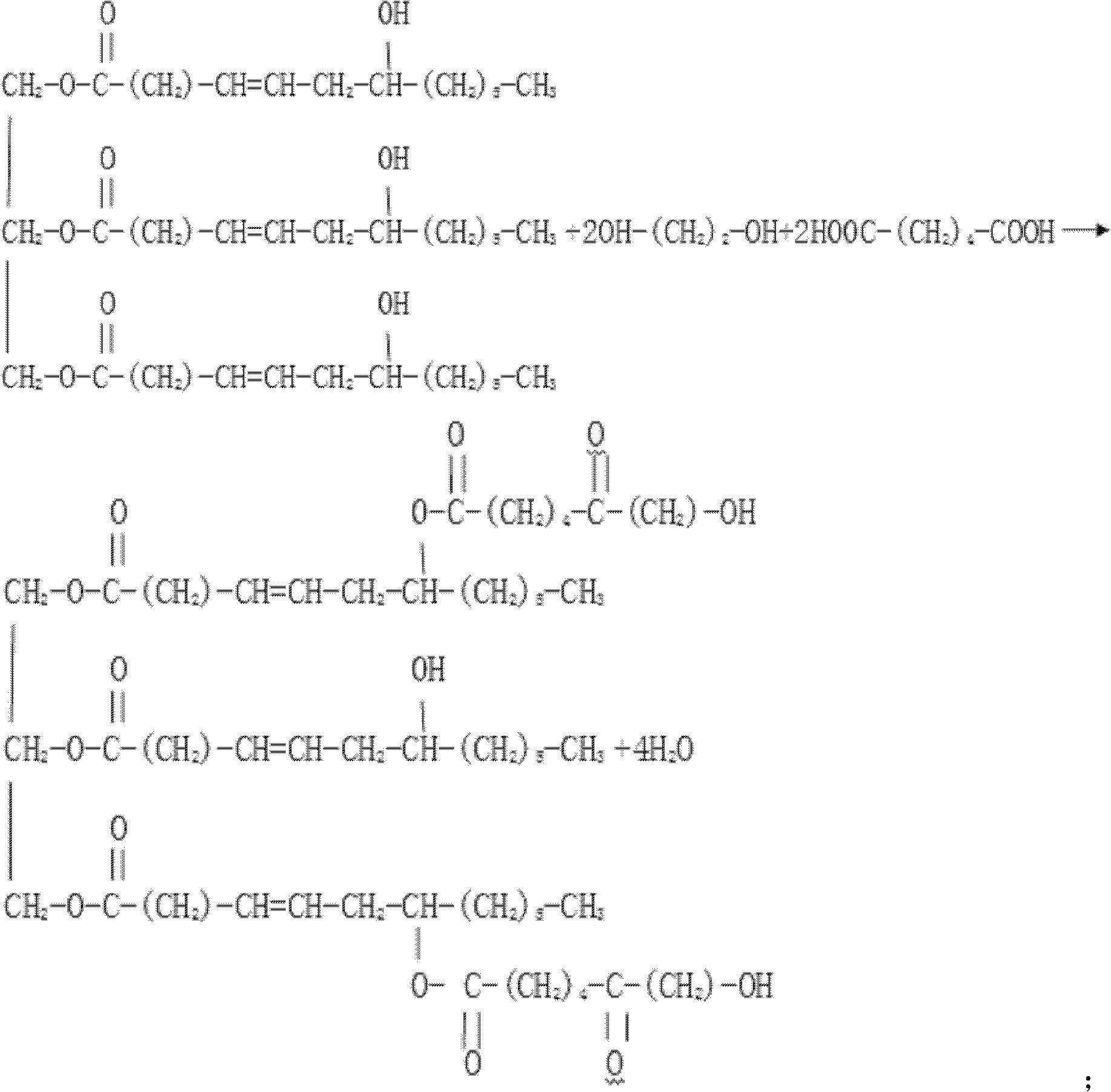

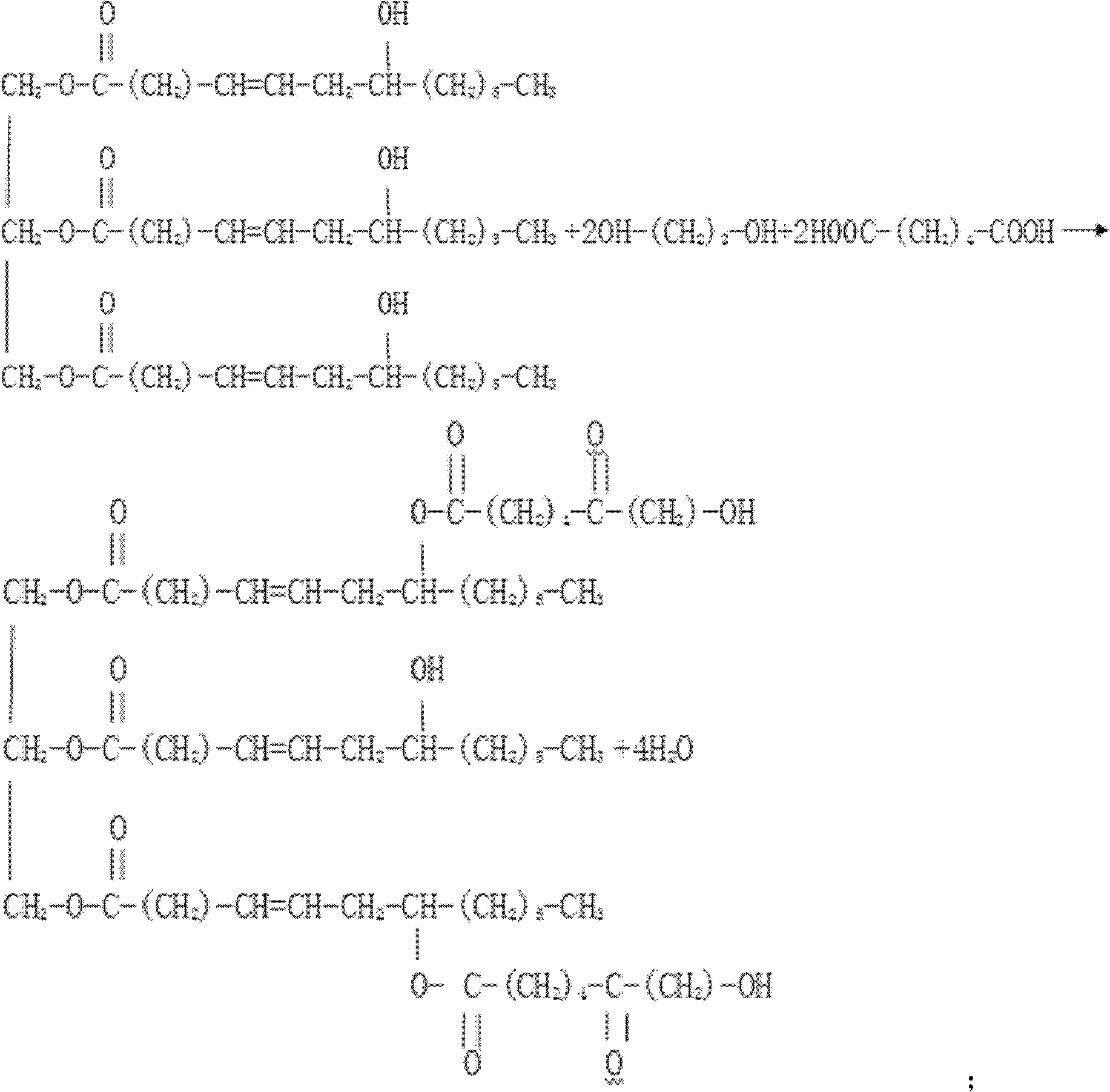

[0028] The modified polyurethane resin described in this example is a segmented polyurethane synthesized from vegetable oil, with an average molecular weight of 10,000-50,000. The preparation method of modified polyurethane resin is: firstly, vegetable oil, ethylene glycol and adipic acid are reacted to generate polyester polyol, and the reaction equation is as follows:

[0029]

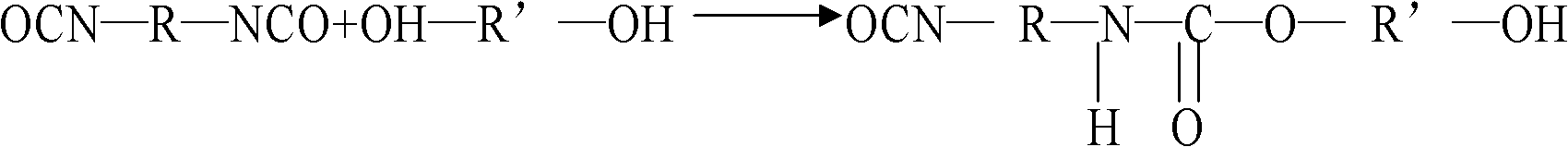

[0030] Then, in a closed environment, the moisture generated by the reaction is removed by distillation under reduced pressure, and the obtained polyester polyol is further reacted with diisocyanate to generate a vegetable oil block-type modified polyurethane resin prepolymer. The reaction equation is as follows:

[0031]

[0032] Among them, R is a hydrocarbon group, and R' is a vegetable oil embedded polyester polyol; it can be seen from the above formula that an excessive amount of diisocyanate reacts with a polyester polyol to first make a prepolymer with an isocyanate group, and then under ...

Embodiment 2

[0035]The benzene-free and ketone-free composite plastic ink described in this embodiment includes modified polyurethane resin, aldehyde and ketone resin, pigment, dispersant, isopropanol, ethanol, and ethyl acetate. The weight of each component is 25 parts of modified polyester polyurethane, 5 parts of aldehyde and ketone resin, 1 part of dispersant, 25 parts of pigment, 10 parts of isopropanol, 20 parts of ethyl acetate and 10 parts of ethanol. The average molecular weight of the vegetable oil-modified polyurethane resin is 12000, the aldehyde and ketone resin is L-872 polyketone resin, the pigment is rutile titanium dioxide, and the dispersant is TM-950. The content of isopropanol and ethyl acetate is more than 99%, the content of benzophenone is less than 0.01%, and the adhesion promoter is titanate coupling agent HY-201.

[0036] The preparation method of the benzene-free and ketone-free composite plastic ink provided in this embodiment is made by the following steps:

...

Embodiment 3

[0044] In the benzene-free and ketone-free composite plastic ink described in this example, the weight content of each component is 25 parts of modified polyurethane resin, 6 parts of polyketone resin, 3 parts of dispersant, 0.5 part of anti-precipitation agent, 0.1 part of wax powder, and 2 parts of accelerator, 10 parts of ethanol, 15 parts of isopropanol, 25 parts of ethyl acetate, 10 parts of pigment, the wax powder is 3620 polyethylene wax, the pigment is permanent red 2BXL, the anti-sedimentation agent For F118.

[0045] The preparation method of the benzo-free and ketone-free composite plastic ink provided by the embodiment, its production process is as follows:

[0046] 1) Pre-dispersion, add modified polyurethane resin, matching resin, dispersant, ethyl acetate, isopropanol, and pigments into the pre-mixing dispersion tank according to the formula ratio of 1 / 3-2 / 3, and start the dispersion machine Stir it evenly, then gradually add the pigment and adhesion promoter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com