Graphene dispersion slurry and organic and inorganic general priming paint modified by graphene dispersion slurry

A technology of dispersing slurry and graphene, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of unstable re-agglomeration of nanoparticles, loss of practical significance, and difficulty in dispersing agglomerates. The effect of improving corrosion resistance, physical and mechanical properties, and good salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

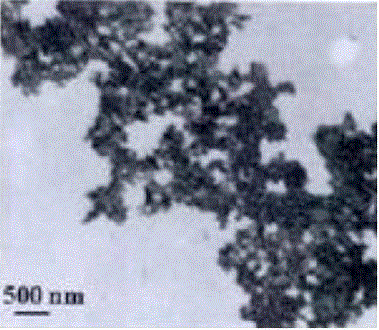

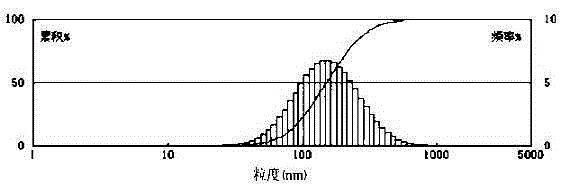

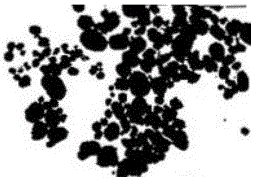

Image

Examples

Embodiment 1

[0030] This embodiment is a water-based universal organic primer, including a first paint material and a curing agent.

[0031] The first paint material is the CYD-127 (or CYD-128) epoxy resin (produced by Baling Petrochemical) that is 20 mass percents, the graphene dispersion slurry that is 8 mass percents, the JFN-600 multifunctional auxiliary that mass percent is 0.5 Agent (Guangzhou Anglian Trading Co., Ltd.), liquid dispersant (produced by Dongguan New Silicon Industry Material Co., Ltd.) with a mass percentage of 1, A200 fumed silica (anti-settling agent) with a mass percentage of 0.5, and a mass percentage of 2 SZP-391 anti-flash rust agent, HD-420 corrosion inhibitor ( Shanghai Pengpan Trading Co., Ltd.), mica powder with a mass percentage of 5, PangelS9 hydrated magnesium silicate (thickener) with a mass percentage of 1, BYK-028 defoamer with a mass percentage of 0.5, BYK-381 leveling agent with a mass percentage of 0.5, The LNBR-40 liquid nitrile rubber (toughening...

Embodiment 2

[0035] This embodiment is an oily organic universal primer, including the first paint material and curing agent. The paint used in this embodiment and the first embodiment is the first paint, and the difference between this embodiment and the first embodiment lies in the difference in the formula of the curing agent and the difference in the mixing ratio of the first paint and the curing agent.

[0036] In this embodiment, the curing agent can also be T-31 phenalkamine curing agent with 30 mass percent, 650 polyamide curing agent with 30 mass percent, K-30 epoxy curing accelerator (Guangzhou Ang) with 5 mass percent United Trading Co., Ltd.) and a mixed solvent composed of xylene and butanol at a mixing ratio of 6:4. The curing agent can be prepared according to the method for preparing the curing agent in Example 1. After the curing agent is prepared, the first paint material and the curing agent are mixed according to the mixing ratio of 10:1 to obtain an oily organic univer...

Embodiment 3

[0038] This embodiment is a water-based inorganic universal primer, which is composed of E777-2 inorganic silicate resin (produced by Wuhan Hurst Materials Co., Ltd.) with a mass percentage of 20-25, and an acrylic elastic resin with a mass percentage of 3-6. Emulsion, graphene dispersion slurry with a mass percentage of 8-12, a multifunctional additive with a mass percentage of 0.2-0.5, a wetting and dispersing agent with a mass percentage of 0.5-1, an anti-sedimentation agent with a mass percentage of 0.5-1, mass Thickener with a mass percentage of 0.5-1, anti-flash rust agent with a mass percentage of 1-3, corrosion inhibitor with a mass percentage of 2-5, mica powder with a mass percentage of 5-8, and a mass percentage of 0.2-0.5 Defoamer, leveling agent with a mass percentage of 0.2-0.5, hydrophobic agent with a mass percentage of 1-3, distilled zinc powder with a mass percentage of 35-45 and purified water.

[0039] The preparation process of this example is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com