Porous material and its preparation method

A technology of porous materials and matrix materials, applied in the field of materials, can solve problems such as poor compatibility and lack of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

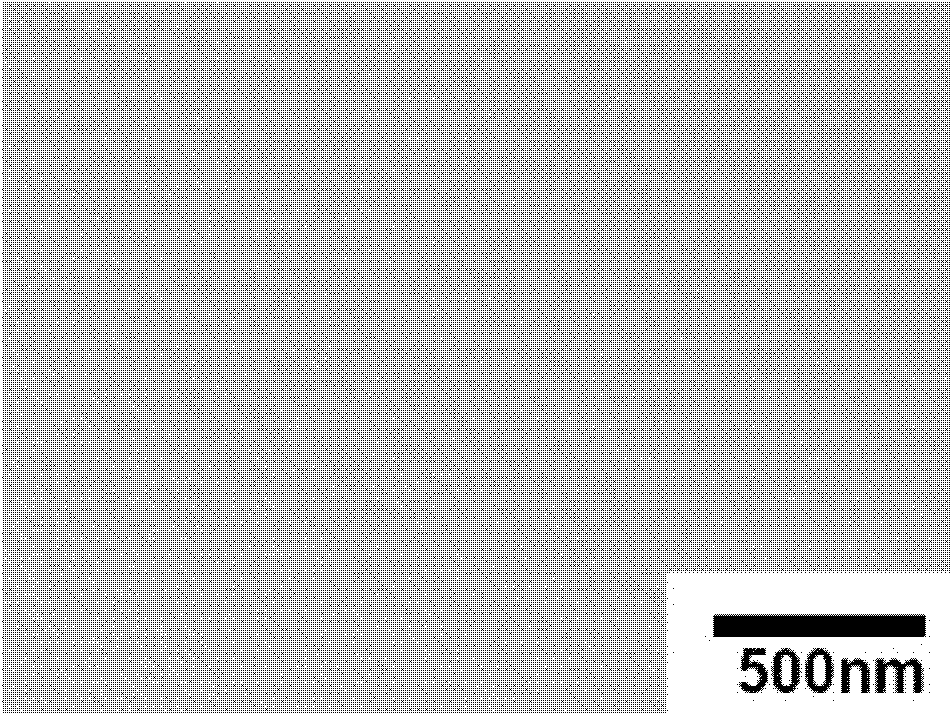

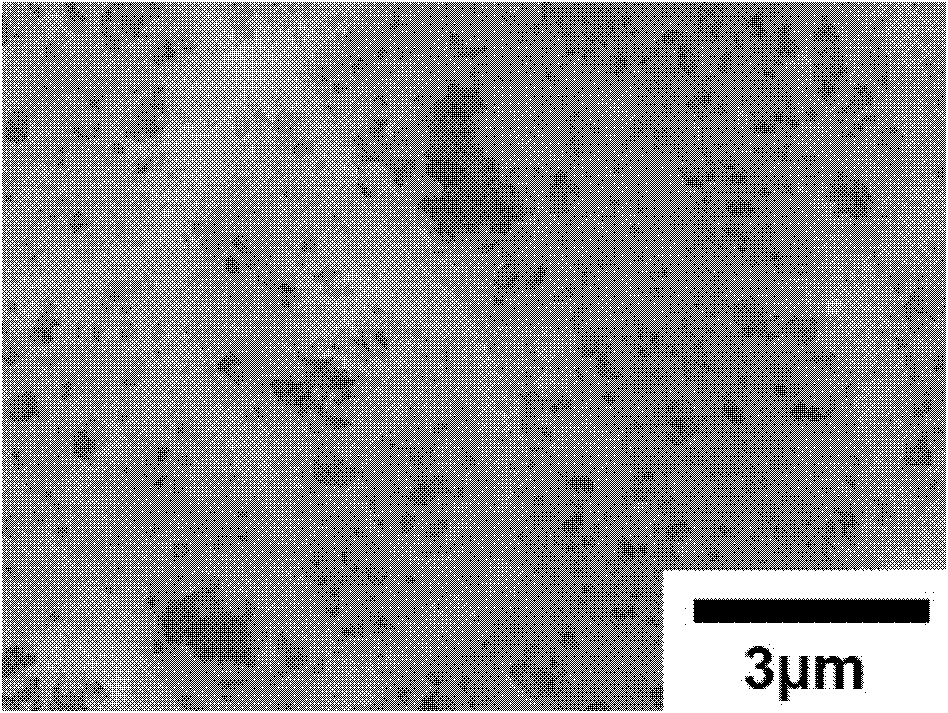

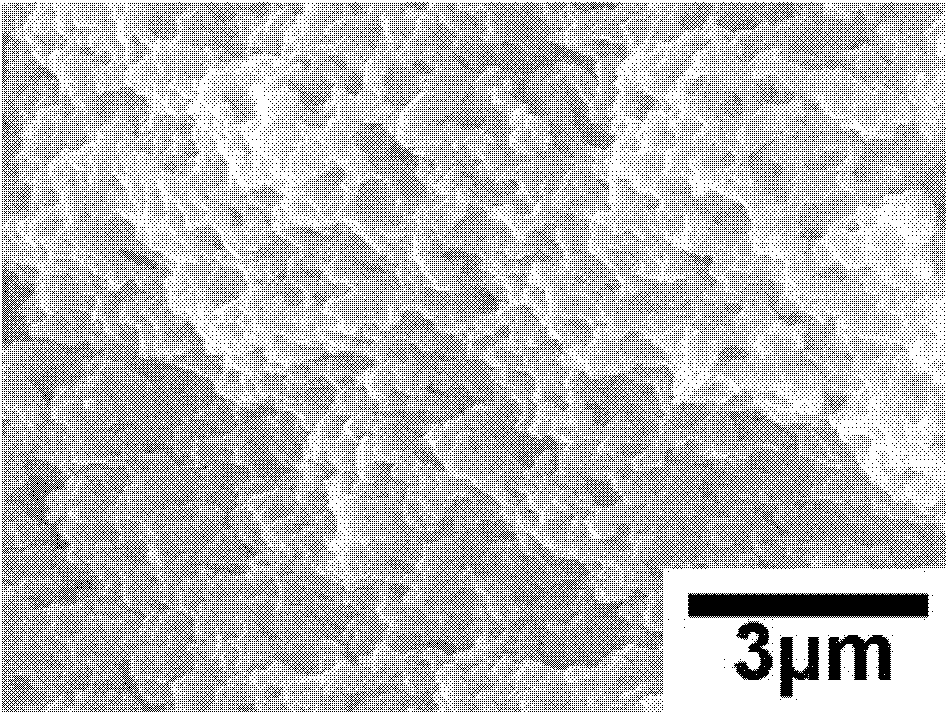

[0040] 0.1g of polyimide prepolymers with a number average molecular weight of 1000 was dissolved in 5g of solvent N, N-dimethylacetamide (DMAc), dispersed uniformly by ultrasonic, added 0.048g terephthalaldehyde, dissolved and dispersed uniformly, Then add 0.052g triethylenetetramine and react at 25°C for 0.5 hours, dry at 80°C for 2 hours to volatilize to form a film, then soak in 2M hydrochloric acid solution for 1 hour, and decompose the Schiff base into terephthalaldehyde under acidic conditions and triethylenetetramine, washed 3 times with 2M hydrochloric acid solution to remove the Schiff base to obtain a polyimide prepolymer porous membrane.

[0041] In order to improve the thermal stability of the polyimide prepolymer porous membrane, the prepolymer porous membrane was cured according to the following steps: heat preservation at 80°C for 1h, heat preservation at 120°C for 1h, heat preservation at 160°C for 1h, heat preservation at 200°C 1h, 250°C for 1h, and 300°C for...

Embodiment 2

[0043] Dissolve 0.1g of polyimide prepolymer with a number-average molecular weight of 5000 in 5g of solvent N,N-dimethylacetamide (DMAc), and disperse evenly by ultrasonic, then add 0.041g of terephthalaldehyde, dissolve and disperse evenly , then add 0.059g tetraethylenepentamine and react at 25°C for 0.5 hours, dry at 80°C for 2 hours to volatilize to form a film, then soak in 2M hydrochloric acid solution for 1 hour, and decompose the Schiff base into terephthalaldehyde and Tetraethylenepentamine was washed three times with 2M hydrochloric acid solution to remove the Schiff base to obtain a polyimide prepolymer porous membrane.

[0044] In order to improve the thermal stability of the polyimide prepolymer porous membrane, the prepolymer porous membrane was cured according to the following steps: heat preservation at 80°C for 1h, heat preservation at 120°C for 1h, heat preservation at 160°C for 1h, and heat preservation at 200°C for 1h , 250° C. for 1 h, and 300° C. for 1 h...

Embodiment 3

[0046] 0.1g of polyimide prepolymer with a number average molecular weight of 3000 was dissolved in 5g of solvent N, N-dimethylacetamide (DMAc), dispersed uniformly by ultrasonic, added 0.055g of terephthalaldehyde, dissolved and dispersed uniformly, Then add 0.045g p-phenylenediamine, react at 25°C for 0.5 hours, dry at 80°C for 2 hours, volatilize and form a film, then soak in 2M hydrochloric acid solution for 1 hour, and decompose the Schiff base into terephthalaldehyde and P-phenylenediamine was washed three times with 2M hydrochloric acid solution to remove the Schiff base to obtain a polyimide prepolymer porous membrane.

[0047] In order to improve the thermal stability of the polyimide prepolymer porous membrane, the prepolymer porous membrane was cured according to the following steps: heat preservation at 80°C for 1h, heat preservation at 120°C for 1h, heat preservation at 160°C for 1h, and heat preservation at 200°C for 1h , 250°C for 1h, 300°C for 1h to form a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com