Series-connected double-wire type combined welding wire for CO2 gas shield high-speed flat fillet weld

A high-speed flat fillet welding and gas shielding technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of lack of paint resistance and achieve high deposition speed, good paint resistance, The effect of increasing the impact value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the invention, the following examples 1 to 7 are used to further illustrate, but the present invention is not limited to the following examples.

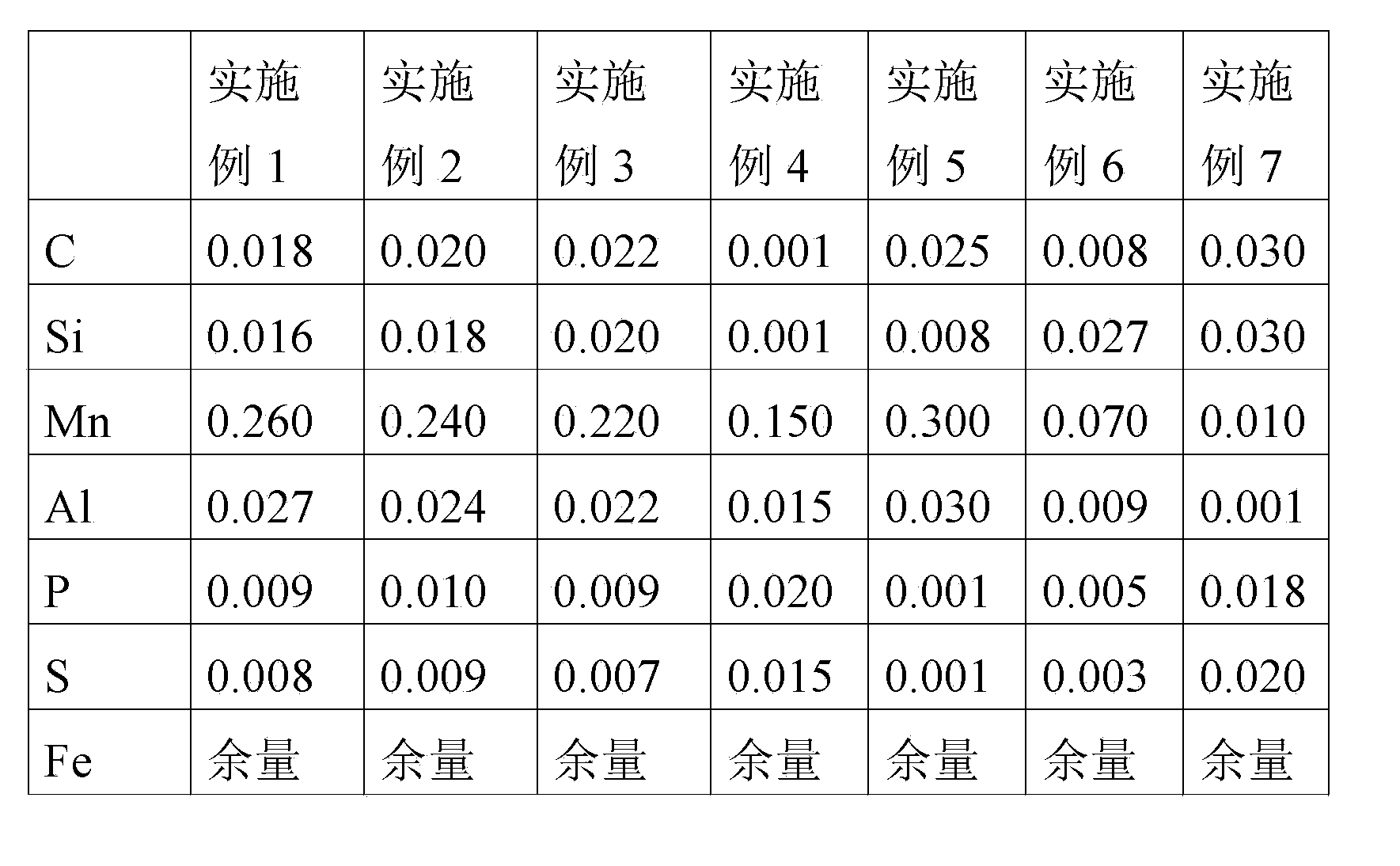

[0031] In the following embodiments, the general manufacturing process in the welding wire production industry is adopted, the first steel strip sheath is prepared according to the components described in Table 1, the metal core powder is prepared according to the components described in Table 2, and the components are prepared according to the components described in Table 3 For the second steel strip sheath, prepare welding flux powder according to the composition described in Table 4, and wrap the metal flux core powder in the first steel strip sheath, and wrap the welding flux powder in the second steel strip sheath. In the skin.

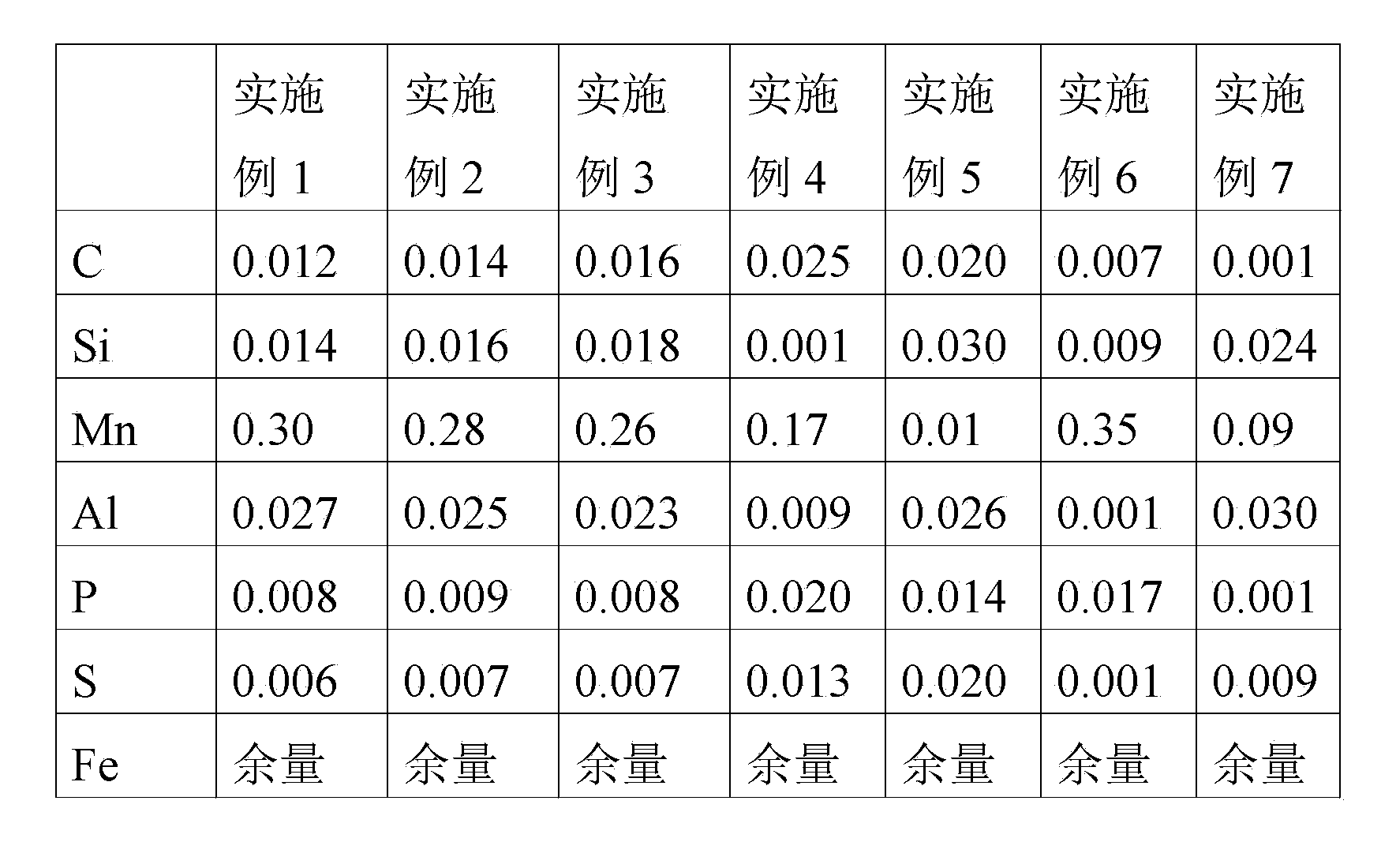

[0032] Table 1 Composition of the first steel strip sheath of the leading electrode wire (%)

[0033]

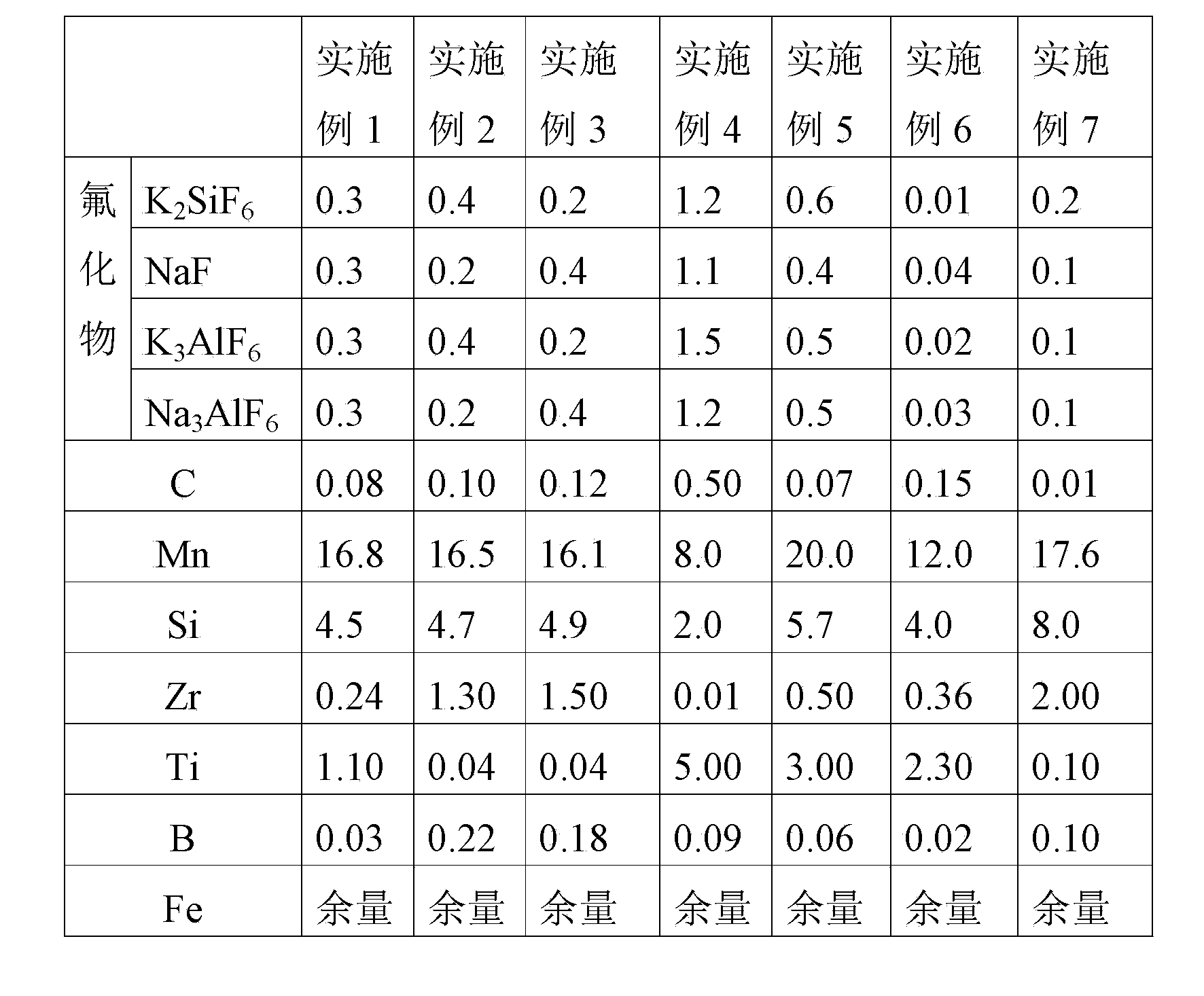

[0034] Table 2 Composition of metal flux core powder of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com