Device system for testing CO release and temperature change in coal incising process

A technology of temperature change and coal body, applied in the field of test system for simulating coal body crushing, can solve problems such as no relevant in-depth research, and achieve the effect of avoiding gas loss, realizing real-time monitoring and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

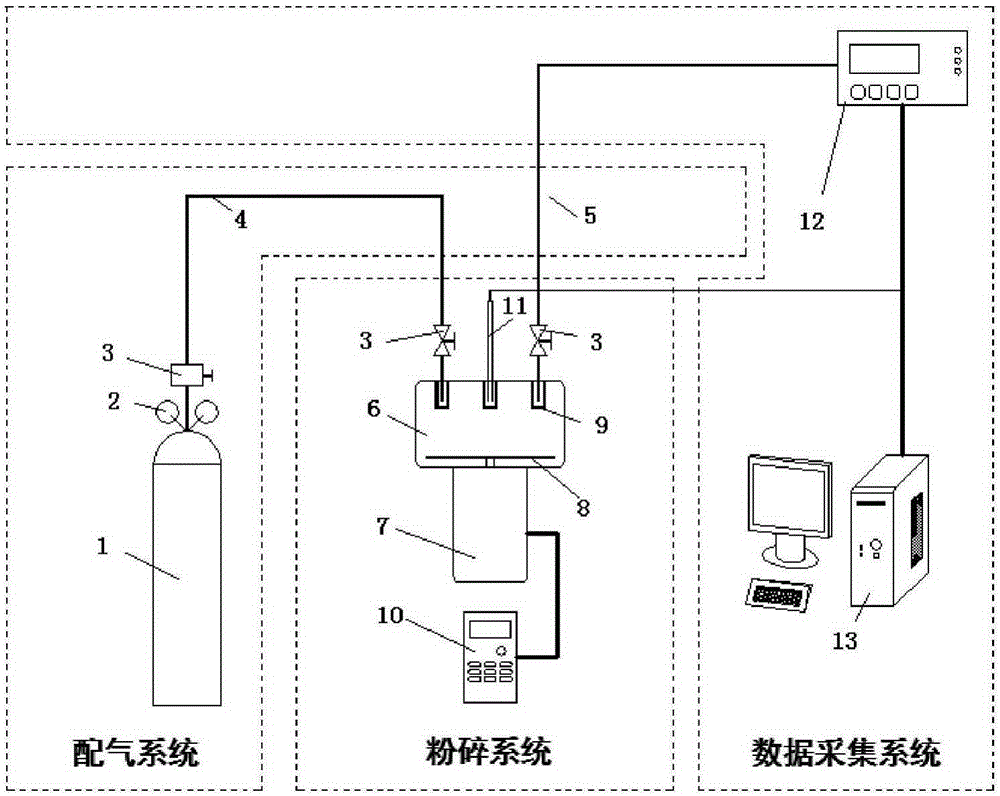

Method used

Image

Examples

Embodiment 1

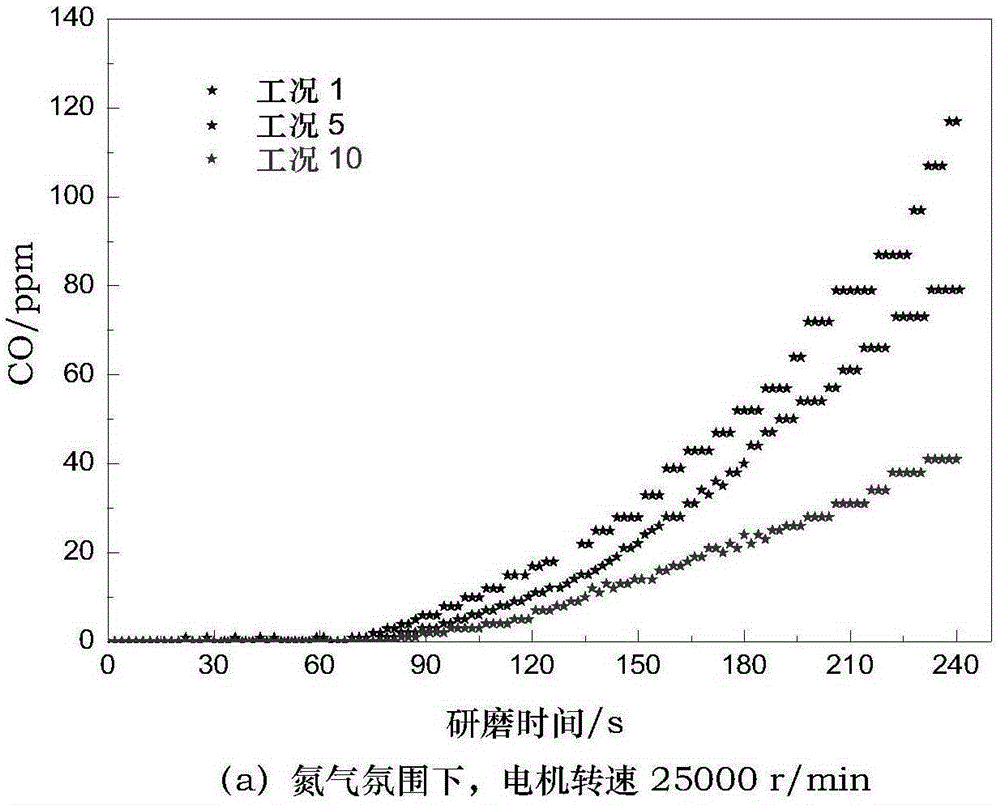

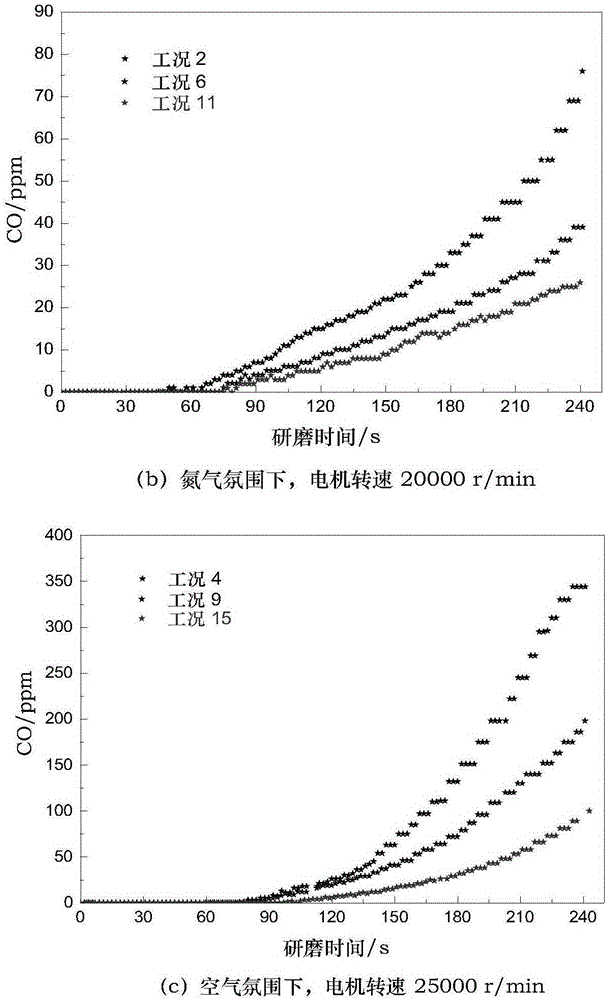

[0030] Example 1: 1. Experimental process and working condition setting: The experiment mainly considered three factors: the quality of the coal sample, the rotational speed of the motor, and the crushing atmosphere. Among them, the coal sample quality is the amount of coal sample that is fully crushed by the blade, and this parameter reflects the amount of coal crushed by the shearer pick in the actual coal mining work. The motor speed is the motor speed of the pulverizer, which can be adjusted by the frequency converter to change the speed of the blade rotation, and this parameter reflects the speed of the drum rotation when the shearer is working. The crushing atmosphere was respectively selected nitrogen atmosphere and air atmosphere.

[0031] Before starting the experiment, first accurately weigh the coal sample to be crushed, put it into the crushing chamber of the pulverizer, and then pass the corresponding atmosphere gas. After the gas composition is stable, close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com