Method for controllably loading precious metal nanometer material on multi-walled carbon nanotube

A technology of multi-walled carbon nanotubes and nanomaterials, applied in the field of controllable loading of ultra-small precious metal nanomaterials on the surface of multi-walled carbon nanotubes, can solve the problems of loss of catalytic activity and catalyst reduction, and achieve high catalytic activity and good stability , The preparation method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

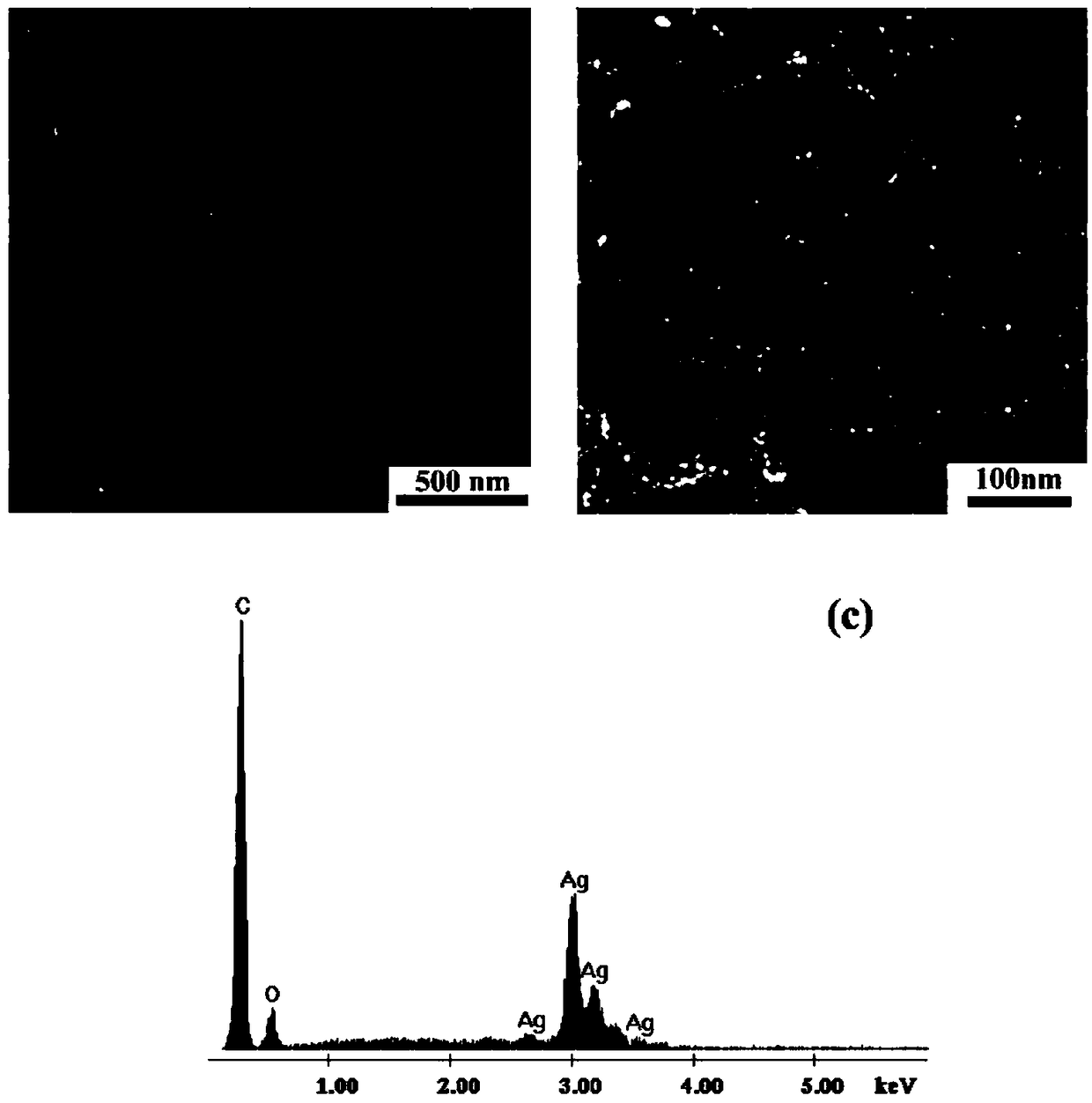

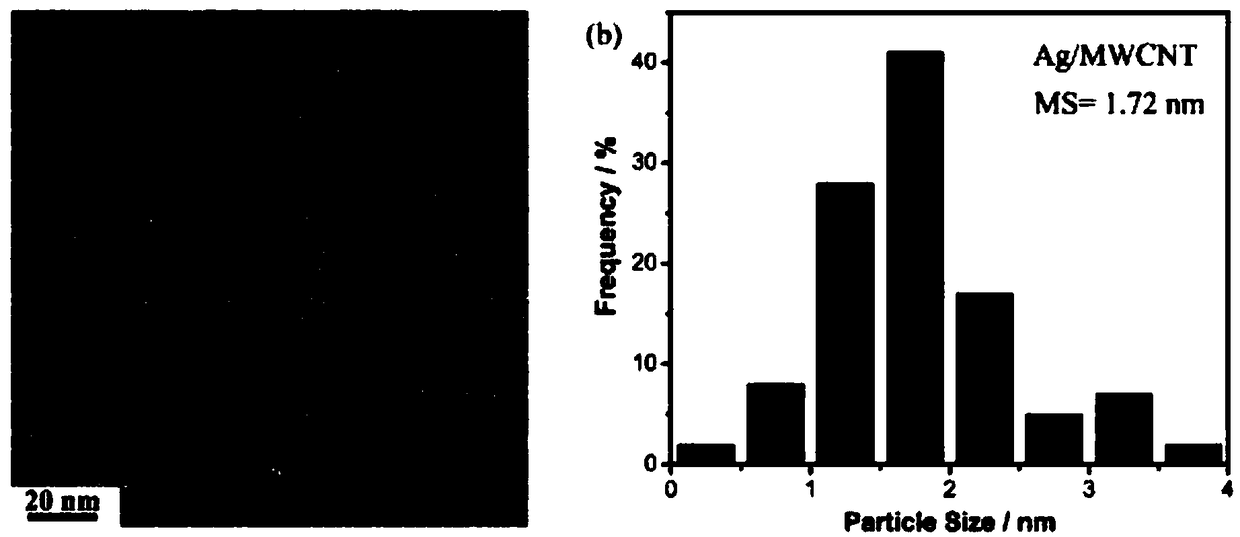

[0027] This embodiment includes the following steps:

[0028] Multi-walled carbon nanotubes were prepared by catalytic assisted CVD. Fe-Mo / MgO is selected as the catalyst, and carbon dioxide is transported into a tube-type high-temperature furnace by using argon-hydrogen mixed gas, and heated at 1000°C for 30 minutes to obtain multi-walled carbon nanotubes.

[0029] Weigh 1 mmol of the prepared multi-walled carbon nanotubes and disperse them into 50 mL of 2 mol / L HCl, and then ultrasonicate (600 W) for 2 hours to remove catalyst particles. The acid-treated carbon nanotubes were rinsed repeatedly with deionized water until neutral to remove chloride ions, and then vacuum-dried at 50° C. for 6 hours to obtain purified multi-walled carbon nanotubes. Disperse the purified multi-walled carbon nanotubes in a mixture of 60ml of concentrated nitric acid and concentrated sulfuric acid (1:2), ultrasonically treat for 18h, filter, wash with deionized water and absolute ethanol repeatedl...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] Multi-walled carbon nanotubes were prepared by catalytic assisted CVD. Fe-Mo / MgO is selected as the catalyst, and carbon dioxide is transported into a tube-type high-temperature furnace by using argon-hydrogen mixed gas, and heated at 1000°C for 30 minutes to obtain multi-walled carbon nanotubes.

[0036]Weigh 1 mmol of the prepared multi-walled carbon nanotubes and disperse them into 50 mL of 2 mol / L HCl, and then ultrasonicate (600 W) for 2 hours to remove catalyst particles. The acid-treated carbon nanotubes were rinsed repeatedly with deionized water until neutral to remove chloride ions, and then vacuum-dried at 50° C. for 6 hours to obtain purified multi-walled carbon nanotubes. Disperse the purified multi-walled carbon nanotubes in a mixture of 60ml of concentrated nitric acid and concentrated sulfuric acid (1:2), ultrasonically treat for 18h, filter, wash with deionized water and absolute ethanol repeatedly...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Multi-walled carbon nanotubes were prepared by catalytic assisted CVD. Fe-Mo / MgO is selected as the catalyst, and carbon dioxide is transported into a tube-type high-temperature furnace by using argon-hydrogen mixed gas, and heated at 1000°C for 30 minutes to obtain multi-walled carbon nanotubes.

[0041] Weigh 1 mmol of the prepared multi-walled carbon nanotubes and disperse them into 50 mL of 2 mol / L HCl, and then ultrasonicate (600 W) for 2 hours to remove catalyst particles. The acid-treated carbon nanotubes were rinsed repeatedly with deionized water until neutral to remove chloride ions, and then vacuum-dried at 50° C. for 6 hours to obtain purified multi-walled carbon nanotubes. Disperse the purified multi-walled carbon nanotubes in a mixture of 60ml of concentrated nitric acid and concentrated sulfuric acid (1:2), ultrasonically treat for 18h, filter, wash with deionized water and absolute ethanol repeatedl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com