Self-assembly rod-shaped manganese-zinc ferrite magnetic material and preparation method thereof

A technology of manganese-zinc ferrite and magnetic materials, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of unfriendly environment, complicated process, easy agglomeration of product particles, etc., and it is easy to control the experimental conditions , Uniform particle size distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

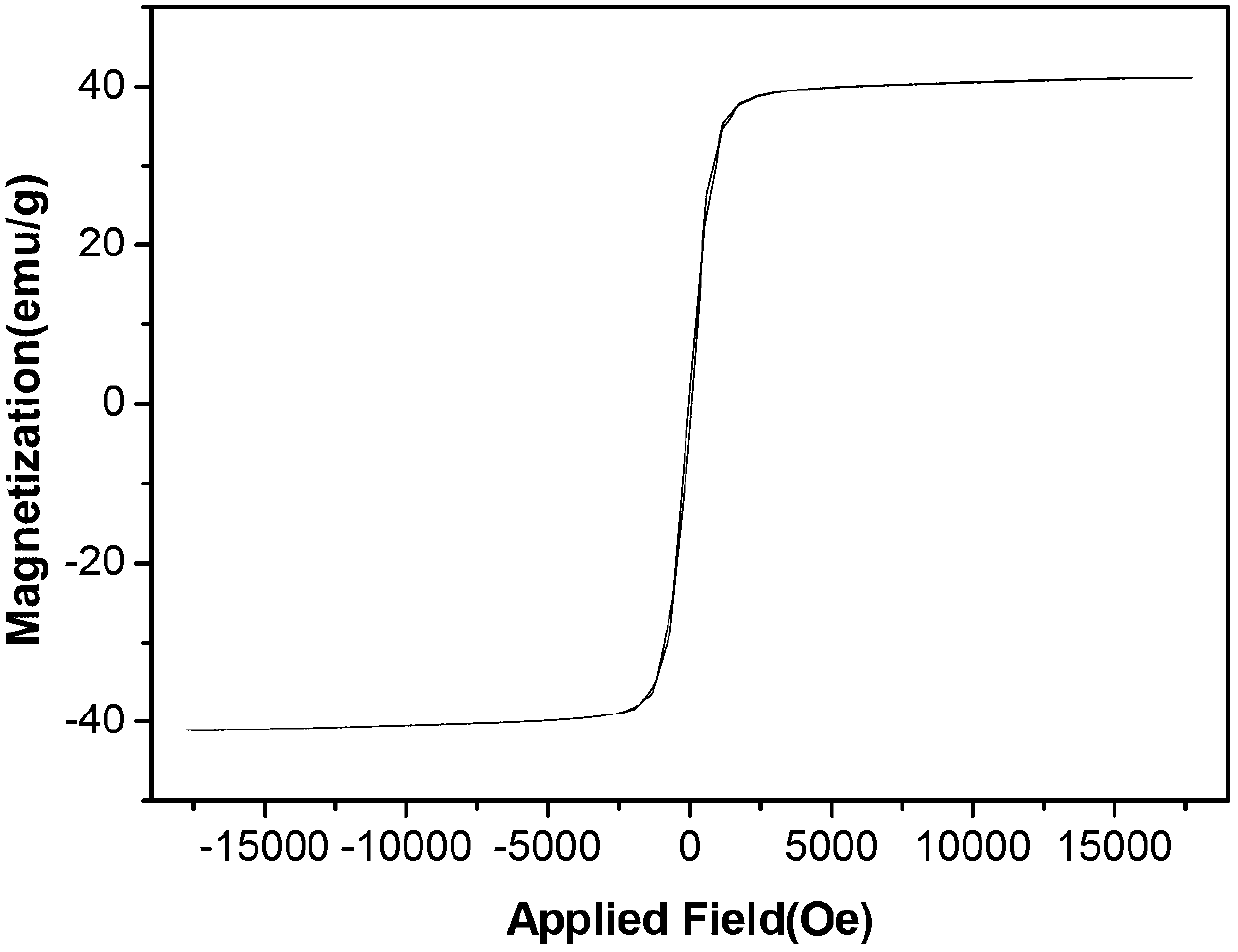

Embodiment 1

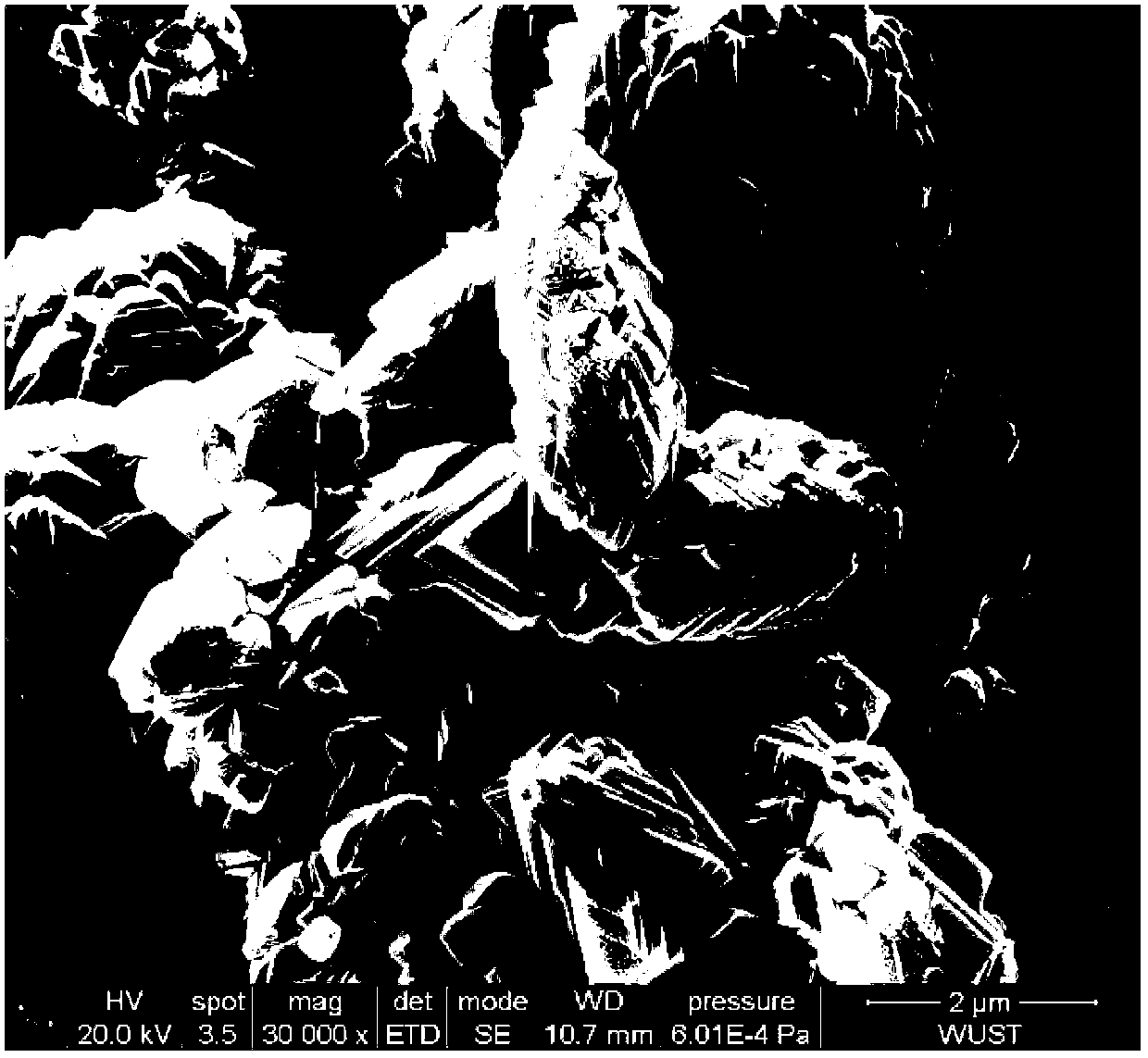

[0042] The self-assembled rod-shaped manganese-zinc ferrite magnetic material provided in this embodiment is self-assembled into submicron rods by octahedral units, and its structural formula is Mn 0.25 Zn 0.75 Fe 2 o 4 The material is obtained by calcining after mixing the reactant and the reaction medium, wherein the reactant at least includes manganese source, zinc source and iron source, and the reaction medium is a chloride salt or a mixture of two chloride salts.

[0043] In this embodiment, manganese source is manganese carbonate, oxide or soluble chloride, sulfate, zinc source is zinc carbonate, oxide or soluble chloride, sulfate, iron source is synthetic Fe 2 o 3 Powder, the reaction medium is sodium chloride, potassium chloride, or a mixture of sodium chloride and potassium chloride.

[0044] Fe in this example 2 o 3 The powder is prepared by solvothermal method, and the specific preparation method is as follows:

[0045] (1) FeCl 3 ·6H 2 O was ground into a...

Embodiment 2

[0058] The self-assembled rod-shaped manganese-zinc ferrite magnetic material provided in this embodiment is self-assembled into submicron rods by octahedral units, and its structural formula is Mn 0.5 Zn 0.5 Fe 2 o 4 , the material is obtained by calcining reactants, wherein the reactants at least include manganese source, zinc source and iron source.

[0059] In this embodiment, manganese source is manganese carbonate, oxide or soluble chloride, sulfate, zinc source is zinc carbonate, oxide or soluble chloride, sulfate, iron source is synthetic Fe 2 o 3 Powder.

[0060] Fe in this example 2 o 3 The powder is prepared by solvothermal method, and the specific preparation method is as follows:

[0061] (1) FeCl 3 ·6H 2 O was ground into a powder, which was then dissolved in deionized water to obtain solution A;

[0062] (2) NH 4 h 2 PO 4 Dissolved in deionized water to obtain solution B;

[0063] (3) Mix solution A and solution B, stir fully with a magnetic stirre...

Embodiment 3

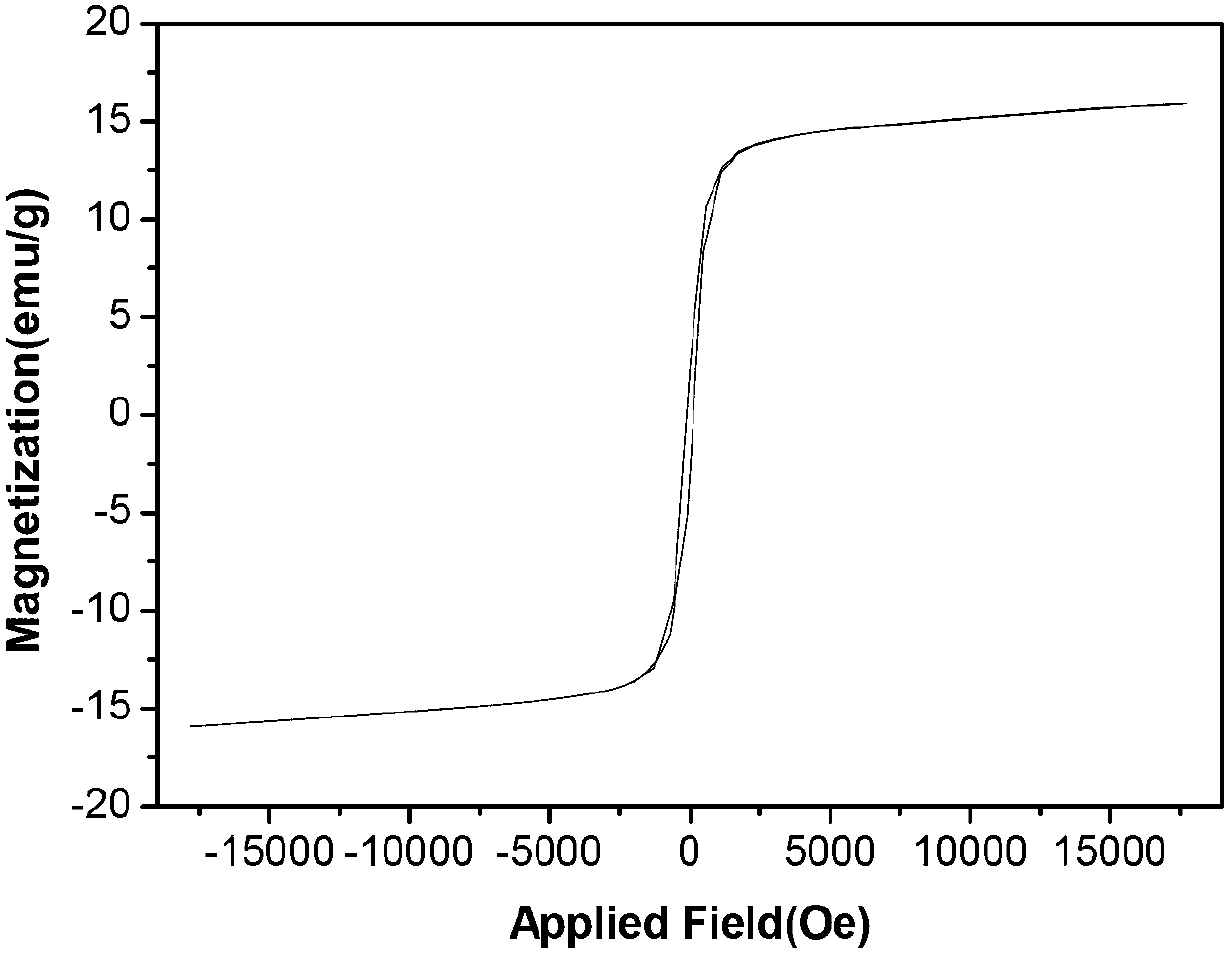

[0074] The self-assembled rod-shaped manganese-zinc ferrite magnetic material provided in this embodiment is self-assembled into submicron rods by octahedral units, and its structural formula is Mn 0.75 Zn 0.25 Fe 2 o 4 The material is obtained by calcining after mixing the reactant and the reaction medium, wherein the reactant at least includes manganese source, zinc source and iron source, and the reaction medium is a chloride salt or a mixture of two chloride salts.

[0075] In this embodiment, manganese source is manganese carbonate, oxide or soluble chloride, sulfate, zinc source is zinc carbonate, oxide or soluble chloride, sulfate, iron source is synthetic Fe 2 o 3 Powder, the reaction medium is sodium chloride, potassium chloride, or a mixture of sodium chloride and potassium chloride.

[0076] Fe in this example 2 o 3 The powder is prepared by a solvothermal method, and the specific preparation method is the same as in Example 1.

[0077] The preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com