Photoresponse oil-water separation filter paper and preparation method thereof

A light-responsive, oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problem that polymers do not have environmental responsiveness, and achieve the effect of easy control of experimental conditions and improved adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

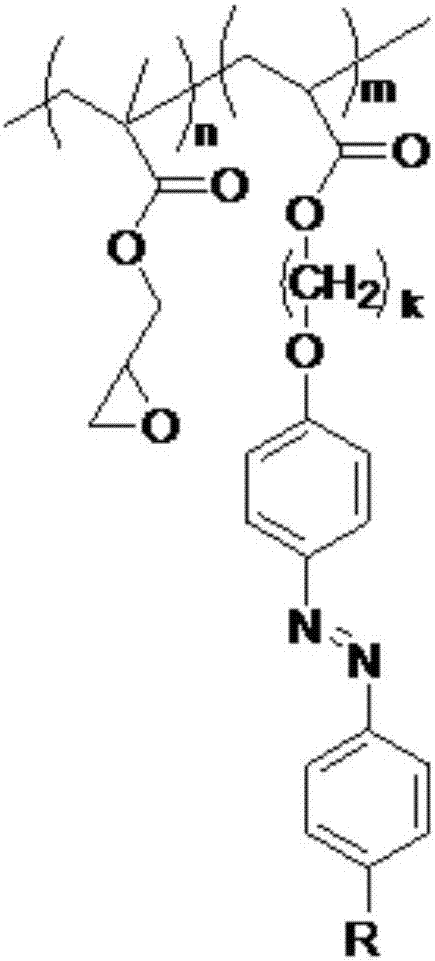

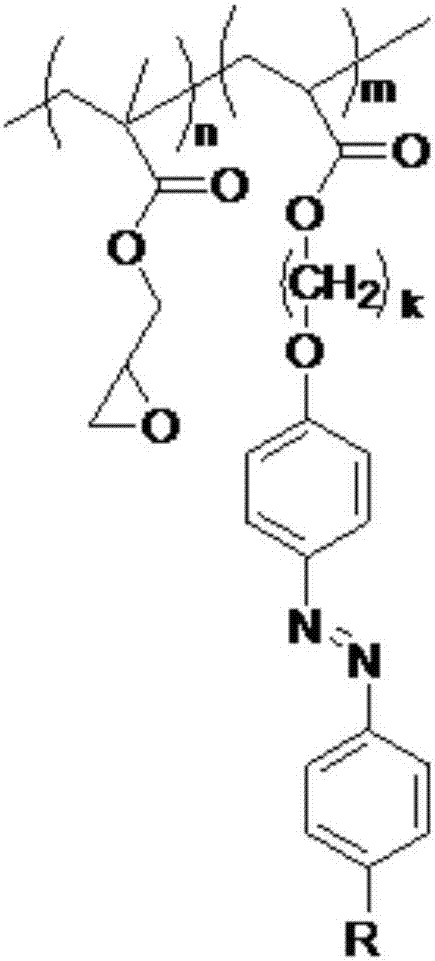

[0024] (1) Preparation of glycidyl methacrylate-6-[4-(4-ethoxyphenylazo)phenoxy]hexyl acrylate copolymer

[0025] In terms of molar ratio, glycidyl methacrylate, 6-[4-(4-ethoxyphenylazo)phenoxy]hexylacrylate, initiator azobisisobutyronitrile (AIBN) were mixed with 10 : The molar ratio of 90:1 is mixed and dissolved in a certain volume of anisole, and the reaction container is subjected to liquid nitrogen freezing-vacuumizing-nitrogen gas treatment, and the cycle is three times. Under nitrogen protection, the reaction vessel was placed in a constant temperature oil bath at 65° C., and reacted for 10 h under electromagnetic stirring. After the system was cooled, an appropriate amount of tetrahydrofuran was added to dilute the product and precipitated in petroleum ether. After re-dissolving and precipitating, vacuum-dry at room temperature for 24 hours to obtain glycidyl methacrylate-6-[4-(4-ethoxyphenylazo)phenoxy]hexylacrylate copolymer.

[0026] (2) In terms of weight ratio,...

Embodiment 2

[0030] (1) Preparation of glycidyl methacrylate-6-[4-(4-ethoxyphenylazo)phenoxy]hexyl acrylate copolymer

[0031] The preparation method is the same as in Example 1.

[0032] (2) In terms of weight ratio, 1.5g of nano-silica particles (with a particle size of 20 to 60 nanometers), 1.0g of glycidyl methacrylate-6-[4-(4-ethoxyphenylazo ) phenoxy]hexyl acrylate copolymer, 0.2g of ethylenediamine, and 50mL of tetrahydrofuran were mixed, and ultrasonicated for 30min until uniformly dispersed;

[0033](3) Completely immerse medium-speed qualitative filter paper (average pore size 30-50 microns) in the mixture, ultrasonically disperse it for 30 seconds, take it out and dry it naturally for 24 hours.

[0034] (4) The oil-water separation experiment is the same as in Example 1.

Embodiment 3

[0036] (1) Preparation of glycidyl methacrylate-6-[4-(4-ethoxyphenylazo)phenoxy]hexyl acrylate copolymer

[0037] The preparation method is the same as in Example 1.

[0038] (2) In terms of weight ratio, 2g of nano-silica particles (with a particle size of 50 to 100 nanometers), 1.0g of glycidyl methacrylate-6-[4-(4-ethoxyphenylazo) Phenoxy]hexyl acrylate copolymer, 0.2g of ethylenediamine, 50mL of tetrahydrofuran were mixed, ultrasonicated for 30min until uniformly dispersed;

[0039] (3) Completely immerse medium-speed qualitative filter paper (average pore size 30-50 microns) in the mixture, ultrasonically disperse it for 30 seconds, take it out and dry it naturally for 24 hours.

[0040] (4) The oil-water separation experiment is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com