A kind of preparation method of oil-water separation membrane for strong acid, strong alkali and high salt environment

A technology of oil-water separation membrane and strong acid, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of complex preparation process, difficult operation, unusability, etc., achieve stable separation efficiency, easy control of experimental conditions, and synthesis The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

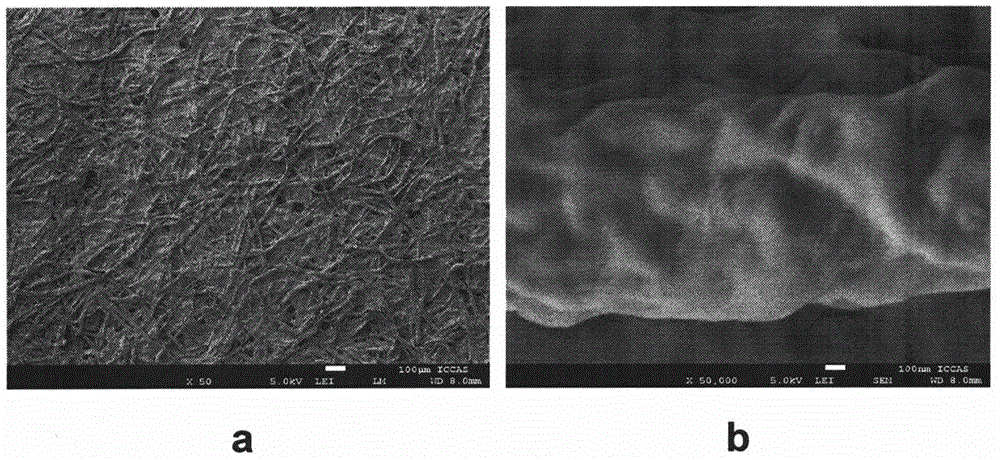

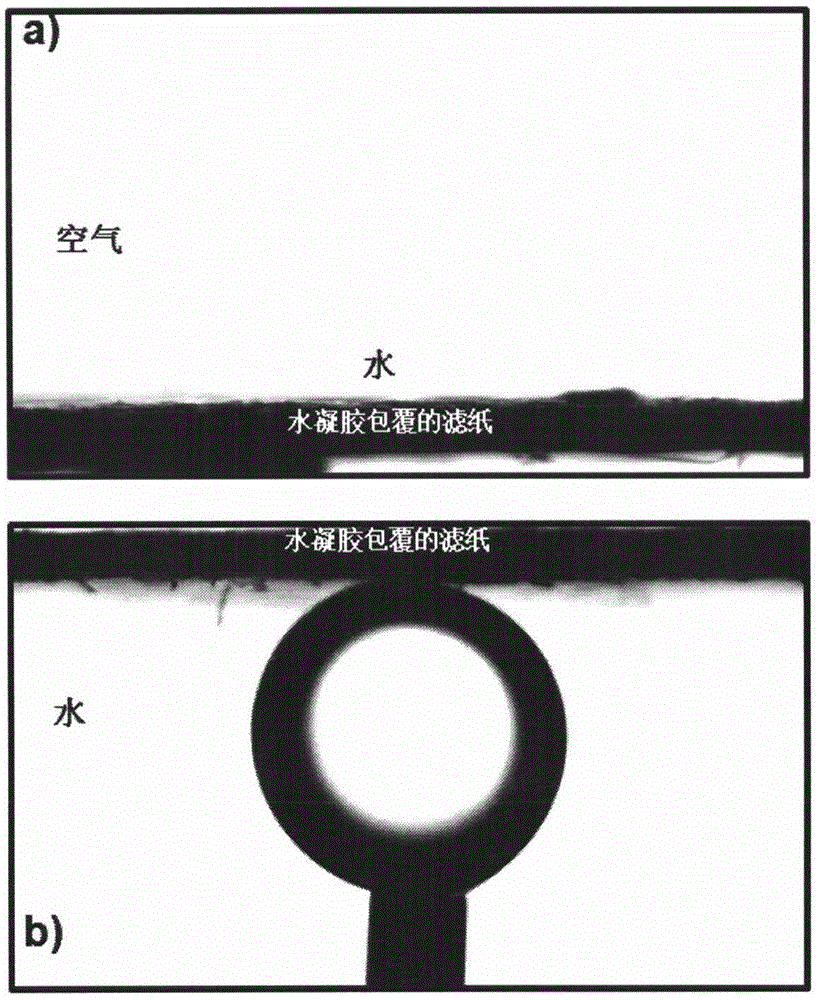

Method used

Image

Examples

Embodiment 1

[0032] a) preparing a polyvinyl alcohol aqueous solution with a concentration of 4%, and adjusting its pH to 2;

[0033] b) Measure 10mL of polyvinyl alcohol aqueous solution, and soak the qualitative medium-speed filter paper in the aqueous solution of hydrophilic polymer for 30min;

[0034] c) introducing the soaked cellulose filter paper into a solution containing glutaraldehyde, and reacting for 12 hours at a temperature of 25°;

[0035] d) The cross-linked filter paper is repeatedly washed with ethanol and deionized water to remove unreacted cross-linking agent and water-soluble polymer, and finally the cross-linked filter paper is dried to constant weight to obtain special wettability Oil-water separation membrane.

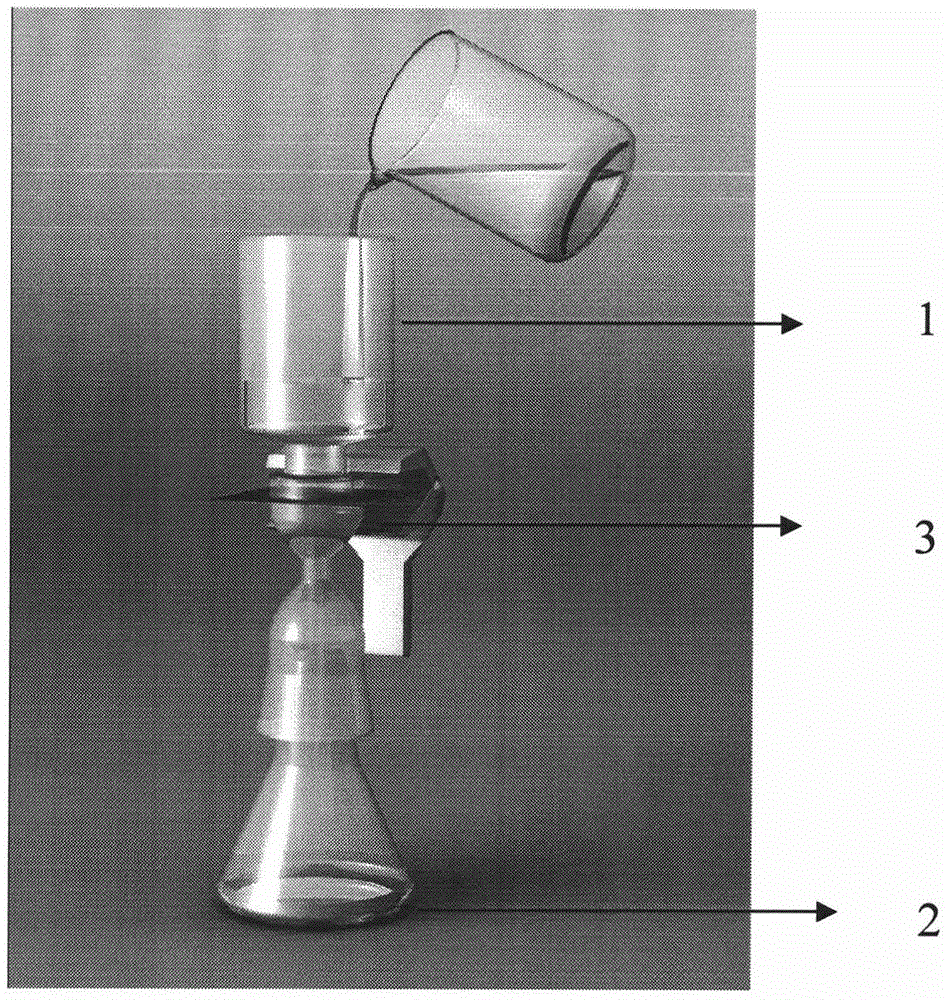

[0036] e) Use such as figure 2 The shown oil-water separation device is used for oil-water separation, and the dried gel filter paper is placed between two glass vessels (such as figure 2 shown), gasoline and 8M concentrated sulfuric acid aqueous soluti...

Embodiment 2

[0038] a) preparing a polyvinyl alcohol aqueous solution with a concentration of 2%, and adjusting its pH to 4;

[0039] b) Measure 10mL of polyvinyl alcohol aqueous solution, and soak the qualitative medium-speed filter paper in the aqueous solution of hydrophilic polymer for 30min;

[0040] c) introducing the soaked cellulose filter paper into a solution containing glutaraldehyde, and reacting for 24 hours at a temperature of 40°;

[0041] d) The cross-linked filter paper is repeatedly washed with ethanol and deionized water to remove unreacted cross-linking agent and water-soluble polymer, and finally the cross-linked filter paper is dried to constant weight to obtain special wettability Oil-water separation membrane.

[0042] f) Use such as figure 2 The shown oil-water separation device is used for oil-water separation, and the dried gel filter paper is placed between two glass vessels (such as figure 2 shown), gasoline and 10M sodium hydroxide aqueous solution are mi...

Embodiment 3

[0044] a) preparing a polyvinyl alcohol aqueous solution with a concentration of 2%, and adjusting its pH to 1;

[0045] b) Measure 10mL of polyvinyl alcohol aqueous solution, and soak the qualitative medium-speed filter paper in the aqueous solution of hydrophilic polymer for 30min;

[0046] c) introducing the infiltrated cellulose filter paper into a solution containing glyoxal, and reacting for 12 hours at a temperature of 50°C;

[0047] d) The cross-linked filter paper is repeatedly washed with ethanol and deionized water to remove unreacted cross-linking agent and water-soluble polymer, and finally the cross-linked filter paper is dried to constant weight to obtain special wettability Oil-water separation membrane.

[0048] g) use such as figure 2 The shown oil-water separation device is used for oil-water separation, and the dried gel filter paper is placed between two glass vessels (such as figure 2 shown), gasoline and saturated sodium chloride aqueous solution ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com