Production process for reducing CO release amount of paper-making reconstituted tobacco and reconstituted tobacco

A technology of reconstituted tobacco leaf and production process, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of high emission and influence on the use of medium and high-end cigarettes, and improve the physical structure, reduce the content of tar and nicotine, and improve the quality of cigarettes. The effect of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

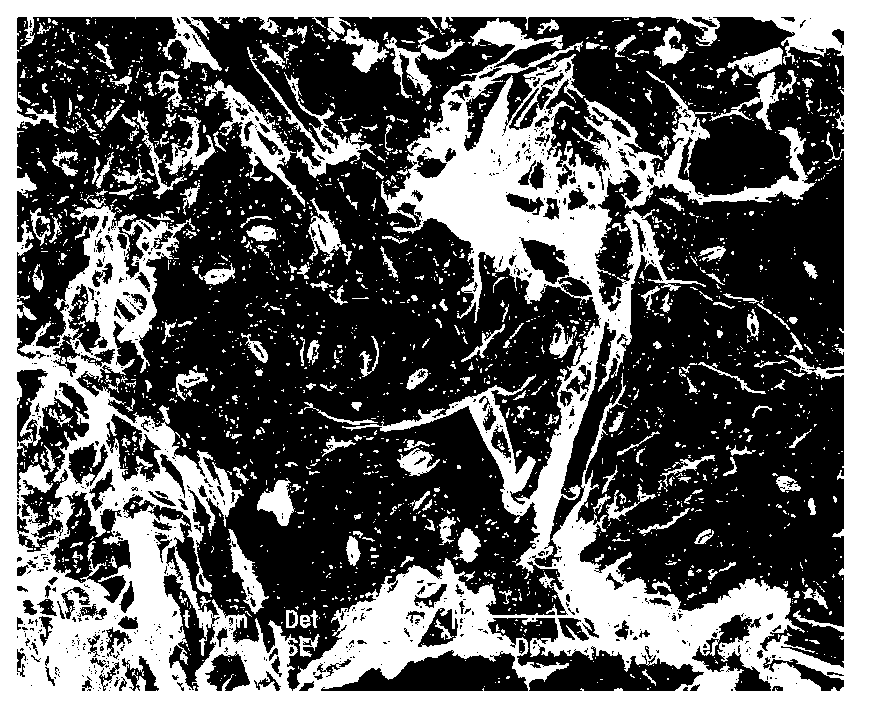

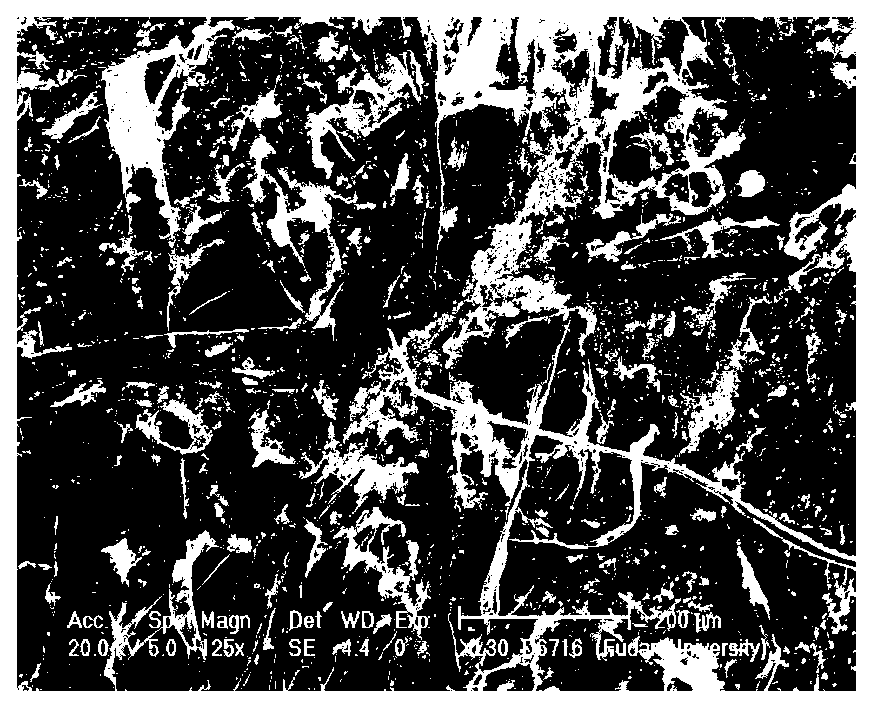

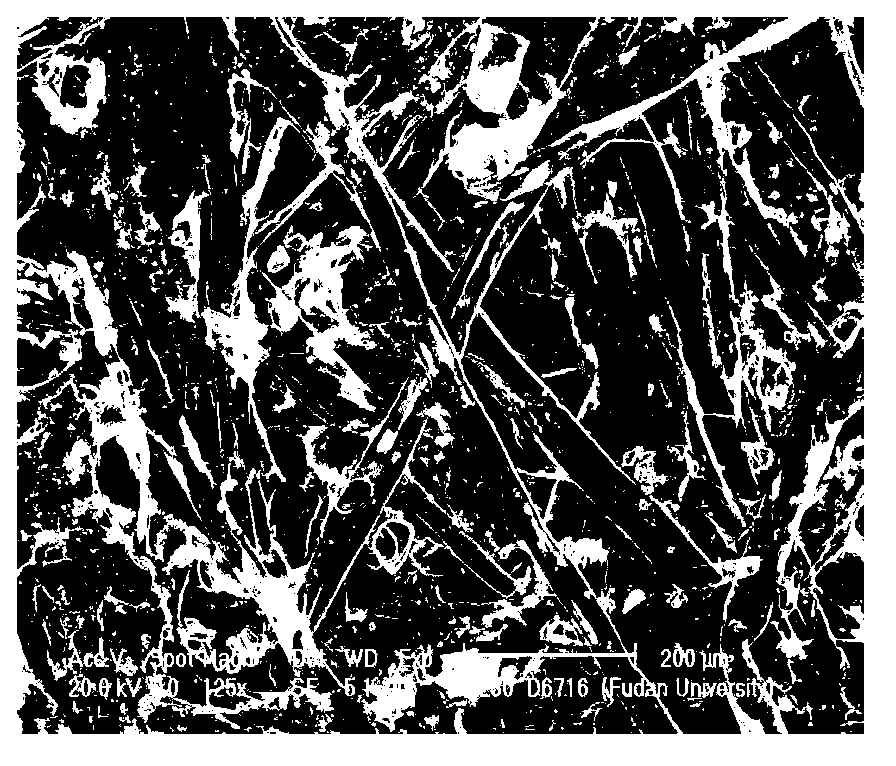

Image

Examples

Embodiment 1

[0024] Small scale experiment:

[0025] Raw materials and their performance parameters:

[0026] Tobacco pulp: beating degree is 25°SR, taken from the production workshop site;

[0027] Wood pulp: beating degree is 32°SR, taken from the production workshop site;

[0028] Filler: PCC, 400 mesh GCC, 600 mesh GCC and 800 mesh GCC, all food grade;

[0029] Retention aid: cationic guar gum, food grade, with a positive charge density of 3.1 mmol / g.

[0030] Instruments and equipment:

[0031] Standard deflattering machine: fiber disintegrator, Changchun Yueming GBJ-A type, Changchun Mingyue Small Testing Machine Co., Ltd.

[0032] Standard film copying device: fast film copying device, P95854KW (RK-2A) type, Austrian PTI;

[0033] Circulating water vacuum pump: Shanghai Yukang SHB-IIIA, Shanghai Yukang Science and Education Instrument Equipment Co., Ltd.

[0034] Shredding machine: Zhengzhou Hengde QS-2A type, Zhengzhou Hengde General Machinery Co., Ltd.

[0035] Electronic a...

Embodiment 2

[0048] Big line experiment:

[0049] Raw material is identical with embodiment 1, and each section processing parameter of large line experiment is as follows:

[0050] 1) Extraction section:

[0051] project Process requirements Feeding formula (Shanghai raw material) Tobacco stem: stem label: mixed piece: mixed powder = 4.5:0.5:3:2 Tobacco stem pre-extraction dosage 450kg / can Tobacco stem pre-extraction time 30min Tobacco stem pre-extraction water addition 1500kg / can Tobacco stem pre-extraction water temperature 65~70℃ Tablets, Final Feeding Quantity Stem stick 50kg / can; mixed slice 300kg / can; mixed powder 200kg / can Primary and secondary extraction time 20min First and second extraction water addition Level 1 4800±300kg / can; Level 2 3300kg / can Primary and secondary extraction water temperature Level 1 60~65℃; Level 2 65~70℃ First-stage double-screw discharge dryness >25% Single screw defibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com