Modified active carbon additive for reducing CO release amount in flue gas and preparation method and application thereof

An activated carbon and release technology, applied in the application, tobacco, e-liquid filter and other directions, can solve the problem of short time, and achieve the effect of simple preparation, good application prospect and reduction of CO release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 1g of polyvinylpyrrolidone with a molecular weight of 1,000,000 to 100g of water, stir to dissolve it into a PVP aqueous solution, add 100g of 1wt% cuprous sulfate aqueous solution, adjust the pH value to 5.0 with acetic acid, and react at 45°C 6hr, the PVP-Cu(I) complex was precipitated. Filtrate, wash the filter residue with water to remove free metal ions, and dry in vacuum to obtain the PVP-Cu(I) complex.

[0034] Add 1g of PVP-Cu(I) complex to 100g of ethanol to form a uniform solution, add 10g of coconut shell activated carbon, stir at room temperature for 30min, filter, and dry the filter residue to obtain an improvement in the amount of CO released in the flue gas. Activated carbon additive;

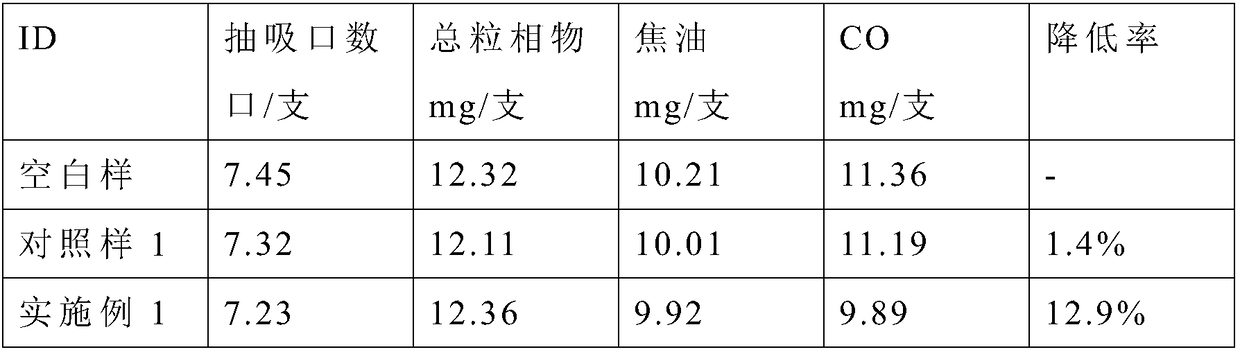

[0035] Add the modified activated carbon into the cigarette mouthpiece rod in an amount of 50 mg / piece, and make a cigarette according to a conventional method. The prepared cigarettes were analyzed for smoke components, and at the same time, a blank sample and a con...

Embodiment 2

[0039] Add 10g of vinylpyrrolidone-maleic acid copolymer with a molecular weight of 1000 into 100g of water, stir to dissolve it into a PVP aqueous solution, add 25g of 10wt% cuprous chloride aqueous solution, and adjust the pH value to 5.0 with hydrochloric acid , At 45°C, react for 6 hours to precipitate the PVP-Cu(I) complex. Filtrate, wash the filter residue with water to remove free metal ions, and dry in vacuum to obtain the PVP-Cu(I) complex.

[0040] Add 10g of PVP-Cu(I) complex to 100g of ethanol to form a uniform solution, add 10g of wood chip activated carbon, stir at room temperature for 30min, filter, and dry the filter residue to obtain a modification that reduces the amount of CO released in the flue gas Activated carbon additive;

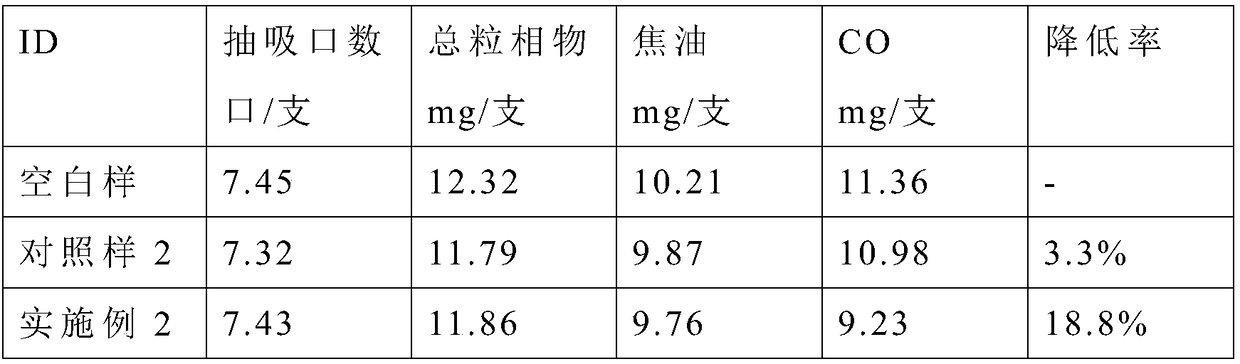

[0041] Add the modified active carbon into the cigarette mouthpiece rod in the amount of 100 mg / stick, and make a cigarette according to a conventional method. The smoke components of the prepared cigarettes were analyzed, and at t...

Embodiment 3

[0045] The polyvinylpyrrolidone of 3g molecular weight 5000 and 3g molecular weight are the vinylpyrrolidone-maleic acid copolymer of 100000, join in 100g water, stir and make it dissolve into PVP aqueous solution, add the 5wt% cuprous acetate aqueous solution of 100g, use After adjusting the pH value to 5.0 with hydrochloric acid, react at 45° C. for 6 hours to precipitate the PVP-Cu(I) complex. Filtrate, wash the filter residue with water to remove free metal ions, and dry in vacuum to obtain the PVP-Cu(I) complex.

[0046] Add 3g of PVP-Cu(I) complex to 100g of ethanol to form a uniform solution, add 1g of walnut shell activated carbon, stir at room temperature for 30min, filter, and dry the filter residue to obtain an improvement in the amount of CO released in the flue gas. Activated carbon additive;

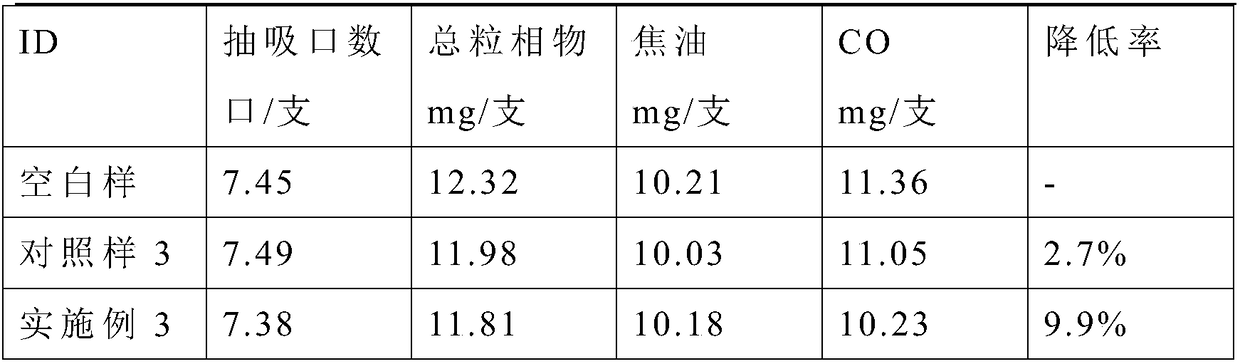

[0047] The modified activated carbon was added to the cigarette mouthpiece in an amount of 10 mg / piece, and a cigarette was made according to a conventional method. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com