Ferrous complex additive for reducing CO emission in flue gas, preparation method and application thereof

An additive and release technology, applied in application, tobacco, food science, etc., can solve problems such as short time, and achieve the effects of simple preparation, low cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

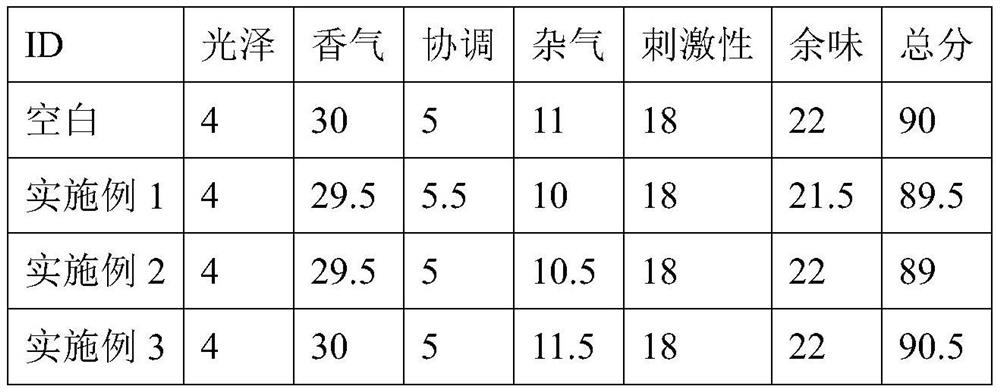

Embodiment 1

[0029] Add 1g of polyvinylpyrrolidone with a molecular weight of 1,000,000 to 100g of water, stir to dissolve it into a PVP aqueous solution, add 100g of 1wt% ferrous sulfate aqueous solution, adjust the pH value to 3 with acetic acid, and react at 30°C 5hr, the PVP-Fe(II) complex was precipitated. Filter and wash with distilled water to remove free metal ions, and dry in vacuum to obtain the PVP-Fe(II) complex additive.

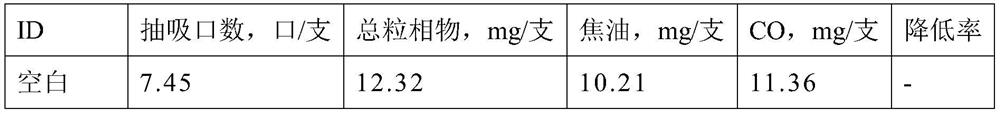

[0030] The additive is added to the mouthpiece of the cigarette in the amount of 10mg / stick, and the cigarette is made according to the conventional method. The smoke components of the prepared cigarettes were analyzed, and the blank sample was a cigarette without any materials added. The results are shown in Table 1:

[0031] Table 1 Measurement results of flue gas data

[0032] ID Number of suction ports, mouth / branch Total particulate matter, mg / cartridge Tar, mg / cartridge CO, mg / piece reduction rate blank 7.45 12.32 10.21 11...

Embodiment 2

[0034] Add 10g of vinylpyrrolidone-maleic acid copolymer with a molecular weight of 1000 into 100g of water, stir to make it dissolve into a PVP aqueous solution, add 25g of 10wt% ferrous chloride aqueous solution, and adjust the pH value to 6 with hydrochloric acid , At 60°C, react for 10 hr to precipitate the PVP-Fe(II) complex. Filter and wash with distilled water to remove free metal ions, and dry in vacuum to obtain the PVP-Fe(II) complex additive.

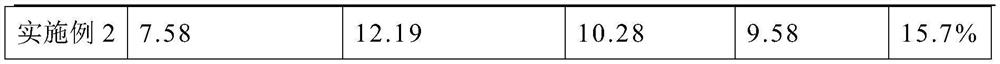

[0035] The additive is added to the mouthpiece rod of the cigarette according to the amount of 100mg / stick, and the cigarette is made according to the conventional method. The smoke components of the prepared cigarettes were analyzed, and the blank sample was a cigarette without any materials added. The results are shown in Table 2:

[0036] Table 2 Measurement results of flue gas data

[0037]

[0038]

Embodiment 3

[0040] The polyvinylpyrrolidone of 3g molecular weight 5000 and 3g molecular weight are the vinylpyrrolidone-maleic acid copolymer of 100000, join in 100g water, stir and make it dissolve into PVP aqueous solution, add the 5wt% ferrous acetate aqueous solution of 100g, use After adjusting the pH value to 4.3 with hydrochloric acid, react at 50° C. for 7 hours to precipitate the PVP-Fe(II) complex. Filter and wash with distilled water to remove free metal ions, and dry in vacuum to obtain the PVP-Fe(II) complex additive.

[0041] The additive is added to the cigarette mouthpiece rod in the amount of 50mg / stick, and the cigarette is made into a cigarette according to a conventional method. The smoke components of the prepared cigarettes were analyzed, and the blank sample was a cigarette without any materials added. The results are shown in Table 3:

[0042] Table 3 Measurement results of flue gas data

[0043] ID Number of suction ports, mouth / branch Total partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com