Flame retardant modified asphalt, flame retardant asphalt concrete and preparation method thereof, and application of slaked lime as flame retardant

A technology of asphalt concrete and modified asphalt, which is applied in the field of flame-retardant asphalt, can solve the problems that the application has not attracted the attention of researchers, and achieve the effects of flame-retardant and smoke suppression, prolonging the ignition time of asphalt, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

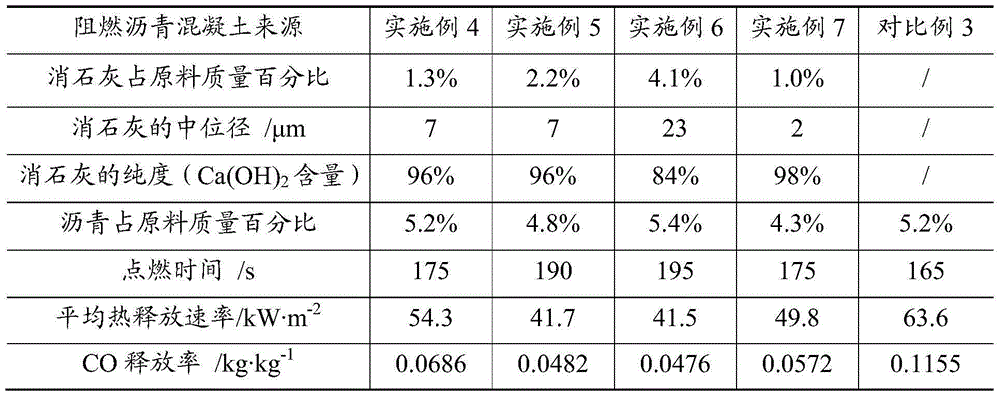

Examples

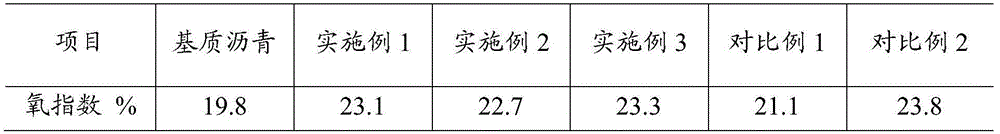

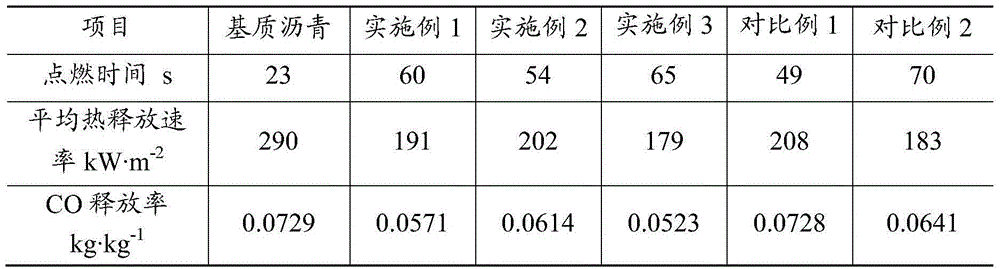

Embodiment 1

[0038] A modified flame retardant asphalt, its preparation method is as follows:

[0039] Take a certain amount of asphalt and heat it to 160±5°C; then add the asphalt into a high-shear mixer emulsifier and stir, and slowly add slaked lime (d 50 =7μm, Ca(OH) 2 Content is 96%), the consumption of slaked lime is 40% of former unmodified asphalt quality, then with the rotating speed of 5000 rev / min stirring 30min; Then with 500 rev / min stirring 15min to drive away the bubble, stop heating and cool; During the process, manual stirring was performed to prevent segregation, and the modified flame-retardant asphalt was finally obtained.

Embodiment 2

[0041] A modified flame retardant asphalt, its preparation method is as follows:

[0042] Take a certain amount of asphalt and heat it to 160±5°C; then add the asphalt into a high-shear mixer emulsifier and stir, and slowly add slaked lime (d 50 =7μm, Ca(OH) 2 Content is 96%), the consumption of slaked lime is 30% of former unmodified asphalt mass, then stirs 30min with the rotating speed of 5000 revs / min; Stirs 15mins with 500 revs / min again to drive away air bubble, stops heating and cools; During the process, manual stirring was performed to prevent segregation, and the modified flame-retardant asphalt was finally obtained.

Embodiment 3

[0044] A modified flame retardant asphalt, its preparation method is as follows:

[0045] Take a certain amount of asphalt and heat it to 160±5°C; then add the asphalt into a high-shear mixer emulsifier and stir, and slowly add slaked lime (d 50 =7μm, Ca(OH) 2 Content is 96%), the consumption of slaked lime is 50% of former unmodified asphalt quality, then with the rotating speed of 5000 rev / min stirring 30min; With 500 rev / min stirring 15min to drive away bubble, stop heating and cool; During the process, manual stirring was performed to prevent segregation, and the modified flame-retardant asphalt was finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com