Method for preparing quinolones compound by using pentacarbonyl iron as CO release source

A technology of iron pentacarbonyl and quinolones is applied in the synthesis field of quinolones to achieve the effects of easy control, mild reaction conditions and high atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

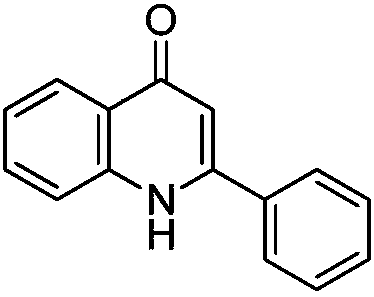

[0013] Preparation of 2-phenylquinolin-1H-4-one with the following structural formula

[0014]

[0015] 0.1095g (0.5mmol) 2-iodoaniline, 66μL (0.60mmol) phenylacetylene, 0.0056g (0.025mmol) palladium acetate, 0.3184g (1.5mmol) potassium phosphate, 0.0431g (0.5mmol) piperazine and 34μL (0.25 mmol) of iron pentacarbonyl and 3mL of anhydrous acetonitrile were added to the Shrek tube, stirred and reacted at 50°C for 10 hours, the reaction was stopped, and the reaction was naturally cooled to room temperature, separated by column chromatography to obtain solid 2-phenylquinolin-1H-4-one , its yield is 86%, and the structural characterization data are: 1 H NMR (600MHz, DMSO) δ11.72(s, 1H), 8.11(dd, J=8.0, 0.9Hz, 1H), 7.87–7.82(m, 2H), 7.78(d, J=8.3Hz, 1H) ,7.71–7.65(m,1H),7.60(dd,J=4.9,1.5Hz,3H),7.35(t,J=7.4Hz,1H),6.34(s,1H); 13 CNMR(151MHz,DMSO)δ 176.93,150.14,140.61,134.25,131.76,130.39,128.96,127.38,124.78,124.67,123.29,118.85,107.25.

Embodiment 2

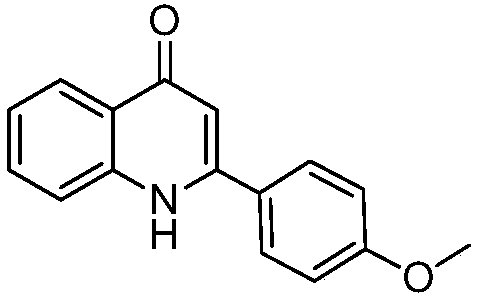

[0017] Preparation of 2-(4-methoxyphenyl)quinolin-1H-4-one with the following structural formula

[0018]

[0019] In Example 1, the phenylacetylene used was replaced with equimolar 4-methoxyphenylacetylene, and other steps were the same as in Example 1 to obtain solid 2-(4-methoxyphenyl)quinoline-1H-4- Ketone, its yield is 81%, and structural characterization data is: 1 H NMR (600MHz, DMSO) δ11.59(s, 1H), 8.09(d, J=7.9Hz, 1H), 7.79(dd, J=25.1, 8.3Hz, 3H), 7.65(t, J=7.5Hz ,1H),7.32(t,J=7.4Hz,1H),7.13(d,J=8.6Hz,2H), 6.31(s,1H),3.85(s,3H); 13 C NMR (151MHz, DMSO) δ176.83, 161.03, 149.68, 140.51, 131.59, 128.80, 126.26, 124.77, 124.64, 123.06, 118.60, 114.37, 106.47, 55.42.

Embodiment 3

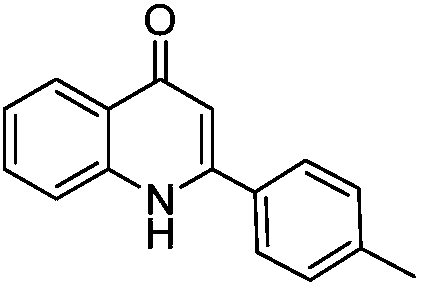

[0021] Preparation of 2-(4-methylphenyl)quinolin-1H-4-one with the following structural formula

[0022]

[0023] In Example 1, the phenylacetylene used is replaced with equimolar 4-methylphenylacetylene, and other steps are the same as in Example 1 to obtain solid 2-(4-methylphenyl)quinolin-1H-4-one, Its yield is 84%, and structural characterization data is: 1 H NMR(600MHz,DMSO)δ11.65(s,1H),8.10(d,J=7.5Hz,1H),7.81–7.61(m,4H), 7.44–7.27(m,3H),6.32(s, 1H),2.40(s,3H); 13 C NMR(151MHz,DMSO)δ176.90, 149.88,140.50,140.31,131.69,131.28,129.51,127.20,124.85,124.68,123.13,118.64, 106.91,20.86.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com