Real-time hole forming cigarette paper and application of real-time hole forming cigarette paper in reducing CO and tar releasing amount of mainstream smoke

A real-time pore-forming technology for mainstream cigarette smoke, applied in application, tobacco, papermaking, etc., can solve problems such as increasing the probability of disease occurrence, decreasing blood oxygen delivery, reducing oxygen concentration, etc., to reduce the release amount and maintain the tar release amount , the effect of reducing CO emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

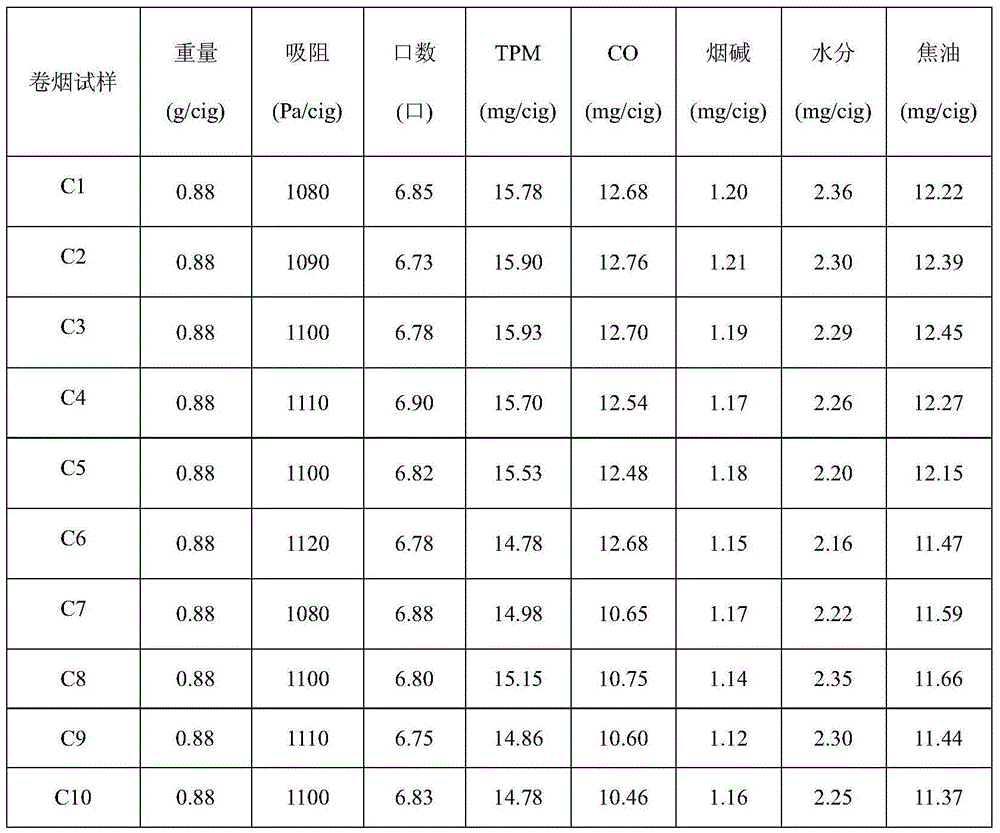

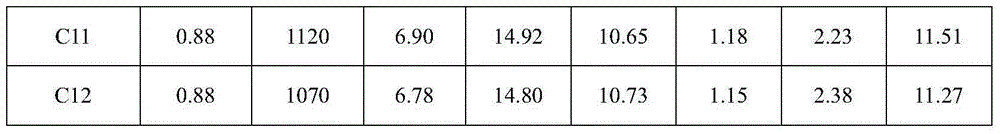

Embodiment 1

[0034] Take 150 kg of softwood pulp, 300 kg of hardwood pulp, 30 kg of MOF-Fe with a particle size of 30-300nm, add 400 kg of calcium carbonate for beating and papermaking, and prepare 10% potassium citrate and 6% lemon Sodium acid mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method, and the cigarette paper is controlled on the equipment. The parameters are: Quantitative 27g m -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00g m -2 (No. P7). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusivity of the paper for t...

Embodiment 2

[0036] Get 160 kilograms of softwood pulp, 320 kilograms of hardwood pulp, 15 kilograms of MOF-Fe, 10 kilograms of MOF-Ca, add 420 kilograms of calcium carbonate for pulping and papermaking, and prepare 10% potassium citrate and 6% citric acid Sodium mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method, and the parameters of the cigarette paper are controlled on the equipment For: Quantitative 27g m -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00g m -2 (No. P8). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusiv...

Embodiment 3

[0038] Get 190 kilograms of softwood pulp, 330 kilograms of hardwood pulp, 15 kilograms of MOF-Fe, 15 kilograms of MOF-Zn, add 450 kilograms of calcium carbonate for beating and papermaking, and prepare 10% potassium citrate and 6% citric acid Sodium mixed additive solution, the prepared additive solution is evenly added to the cigarette paper in the sizing section of the cigarette paper production through the metering rod film transfer sizing machine, and the cigarette paper is produced according to the conventional papermaking method, and the parameters of the cigarette paper are controlled on the equipment For: Quantitative 27g m -2 , the air permeability is 60CORESTA, the amount of additive added in the cigarette paper is 1.00g m -2 (No. P9). The paper diffusivity was tested by Sodim's automatic paper diffusivity meter. The test process for the change of the diffusivity of the test paper before and after heating is as follows: mark the test area when testing the diffusiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com