Plating process for low-nickel non-cyanogen alkalescent zinc-nickel alloy

An electroplating process and zinc-nickel alloy technology, applied in the field of alloy electroplating, can solve the problems of unfavorable practical application in production sites and high cost, and achieve the effects of convenient industrial application, low cost and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

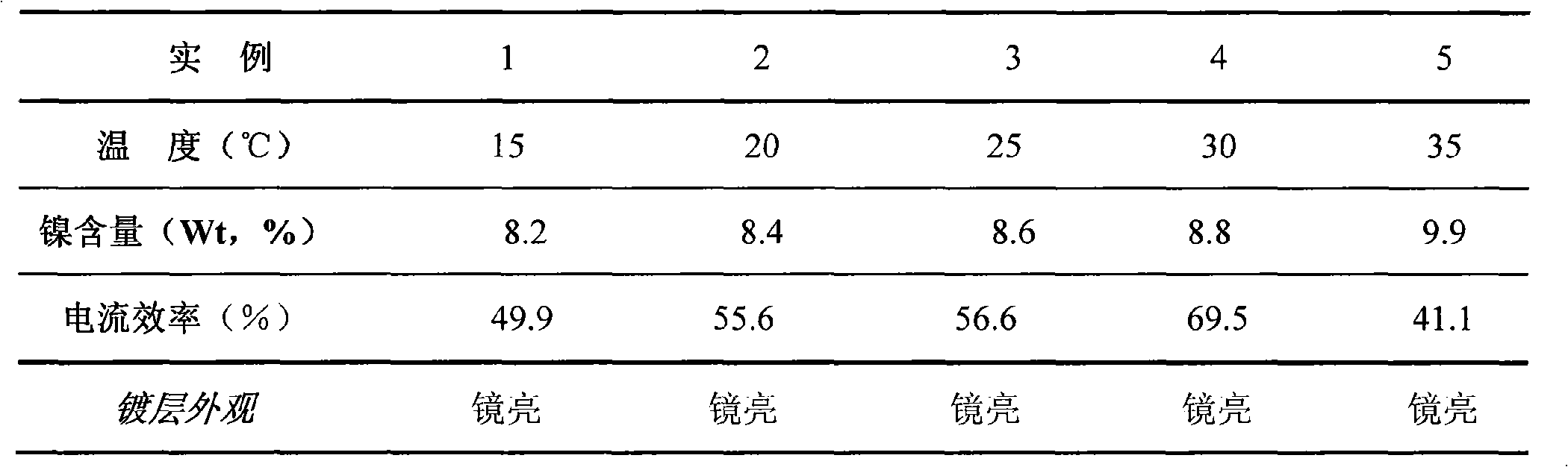

[0022] Example 1-5: Effect of Temperature on Nickel Content and Current Efficiency of Coating

[0023] Plating solution composition: add ZN-1A additive 8ml / liter, ZN-1B additive 2ml / liter, nickel complex 60ml / liter, nickel sulfate 8g / liter to the basic solution. Prepare 1 liter of solution according to the above concentration, use zinc plate or nickel plate as anode, 2 square centimeter iron plate as cathode, and use 2A / dm 2 The current density was electroplated at different temperatures for 20 minutes, and the results were as follows:

[0024]

example 6-10

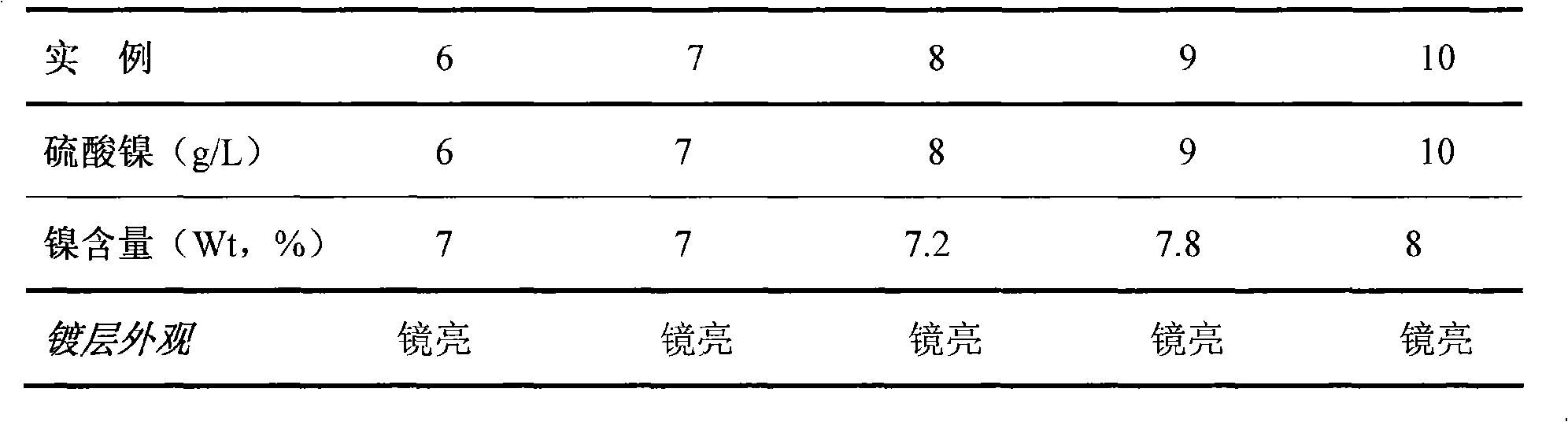

[0025] Example 6-10: The influence of the amount of nickel sulfate on the nickel content of the coating

[0026] Plating solution composition: add ZN-1A additive 8ml / liter, ZN-1B additive 2ml / liter, nickel complex 60ml / liter, nickel sulfate 8g / liter to the basic solution. Prepare 1 liter of solution according to the above concentration, use zinc plate or nickel plate as anode, 2 square centimeter iron plate as cathode, and use 2A / dm 2 The current density was electroplated at 26°C for 20 minutes, and the results were as follows:

[0027]

example 11-14

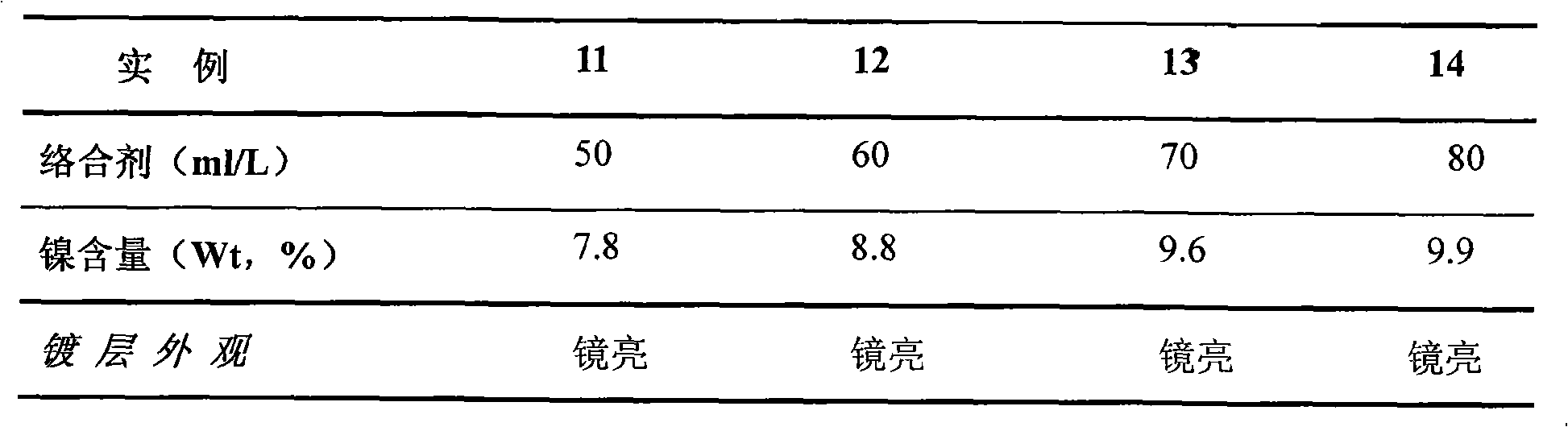

[0028] Example 11-14: The influence of the amount of complexing agent on the nickel content of the coating

[0029] Plating solution composition: add ZN-1A additive 8ml / liter, ZN-1B additive 2ml / liter, nickel sulfate 8g / liter to the basic solution, and the concentration of the complex is changed according to the test requirements. Prepare 1 liter of solution according to the above concentration, use zinc plate or nickel plate as anode, 2 square centimeter iron plate as cathode, and use 2A / dm 2 The current density was electroplated at 25°C for 20 minutes, and the results were as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com