Super capacitor and preparation method thereof

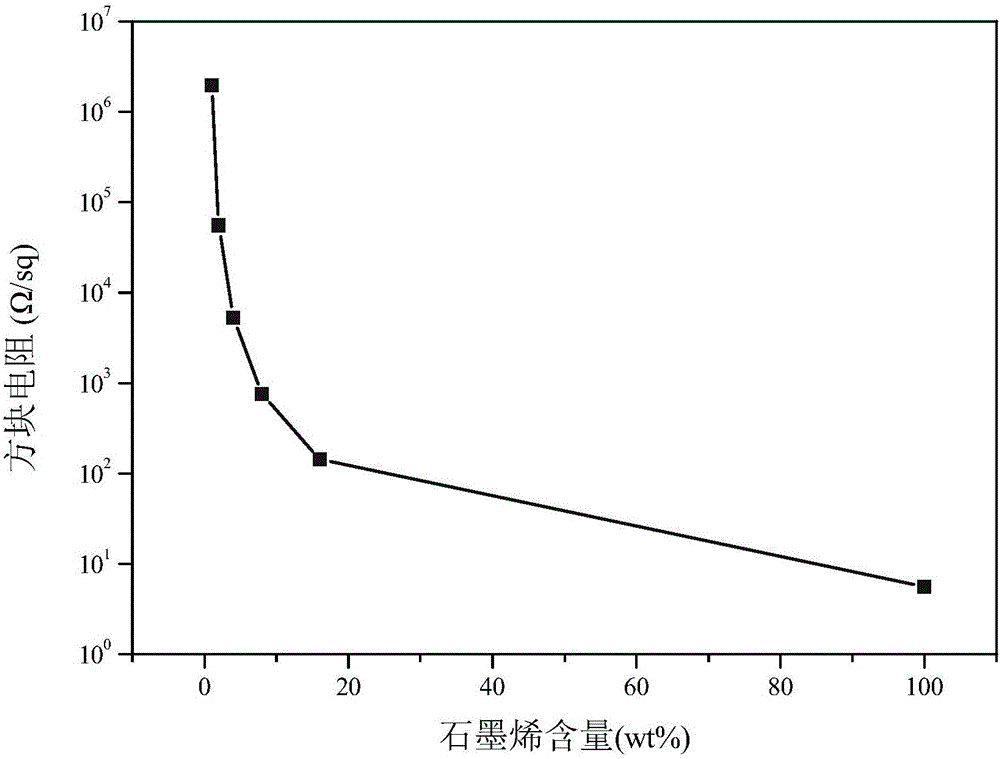

A supercapacitor, ultrasonic dispersion technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of agglomeration and stacking, difficulty in mass production, etc., to prevent agglomeration, avoid loss, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 0.192g of graphite oxide (prepared by the improved Hummers method) is added to a beaker with 80ml of ultrapure water, stirred evenly for 20min, then the beaker is transferred to the cell disruptor, and then the cell disruptor (30 ℃, 400W) ultrasonic for 10min. A graphene oxide aqueous dispersion with a graphene oxide concentration of 0.0024 g / ml was obtained.

[0035] (2) Cut 2.208g of waste newspapers (after vacuum drying) into pieces and put them into a pulp deflaking machine, add 1000ml of water to decompose at 10,000 rpm. A pulp of approximately 0.22% consistency was obtained.

[0036] (3) Add 0.01g of cationic polyacrylamide into a beaker filled with 10ml of ultrapure water, and stir at 100rpm for 12h. An aqueous solution of cationic polyacrylamide with a concentration of about 0.001 g / ml was obtained.

[0037] (4) Add 3.84ml of the cationic polyacrylamide aqueous solution in (3) to the cellulose pulp in (2), and stir slowly with a glass rod for 2 minutes. ...

Embodiment 2

[0041] (1) Add 0.192g of graphite oxide (prepared by the improved Hummers method) into a beaker containing 80ml of ultrapure water, stir evenly for 20min, then transfer the beaker to an ultrasonic cleaner, 80W, 60°C for 2h. A graphene oxide aqueous dispersion with a graphene oxide concentration of 0.0024 g / ml was obtained.

[0042] (2) Add 2.208g of coniferous wood pulp slurry (after vacuum drying) into the pulp deflaking machine, add 1000ml of water to deflank at 15,000 rpm. A softwood pulp with a consistency of about 0.22% is obtained.

[0043] (3) Add 0.01 g of chitosan quaternary ammonium salt into a beaker containing 10 ml of ultrapure water, and stir at 100 rpm for 12 h. A chitosan quaternary ammonium salt aqueous solution with a concentration of about 0.001 g / ml was obtained.

[0044] (4) Add 3.84ml of the chitosan quaternary ammonium salt aqueous solution in (3) to the cellulose pulp in (2), and slowly stir for 2 min with a glass rod. Then add the graphene oxide aqu...

Embodiment 3

[0048] (1) 0.192g of graphite oxide (prepared by the improved Hummers method) is added to a beaker with 80ml of ultrapure water, stirred evenly for 20min, then the beaker is transferred to the cell disruptor, and then the cell disruptor (30 ℃, 400W) ultrasonic for 10min. A graphene oxide aqueous dispersion with a graphene oxide concentration of 0.0024 g / ml was obtained.

[0049] (2) Add 2.208g of coniferous wood pulp slurry (after vacuum drying) into the pulp deflaking machine, add 1000ml of water to deflank at 15,000 rpm. A softwood pulp with a consistency of about 0.22% is obtained.

[0050] (3) Add 0.01g of cationic polyacrylamide into a beaker filled with 10ml of ultrapure water, and stir at 100rpm for 12h. An aqueous solution of cationic polyacrylamide with a concentration of about 0.001 g / ml was obtained.

[0051] (4) Add 3.84ml of the cationic polyacrylamide aqueous solution in (3) to the cellulose pulp in (2), and stir slowly with a glass rod for 2 minutes. Then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com