Special ecological board decoration base paper and preparation method thereof

A technology for decorating base paper and ecological board, applied in the field of papermaking, can solve the problems of high light fastness and difficulty in titanium dioxide, and achieve the effects of prolonging the service life, improving the retention rate and increasing the affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

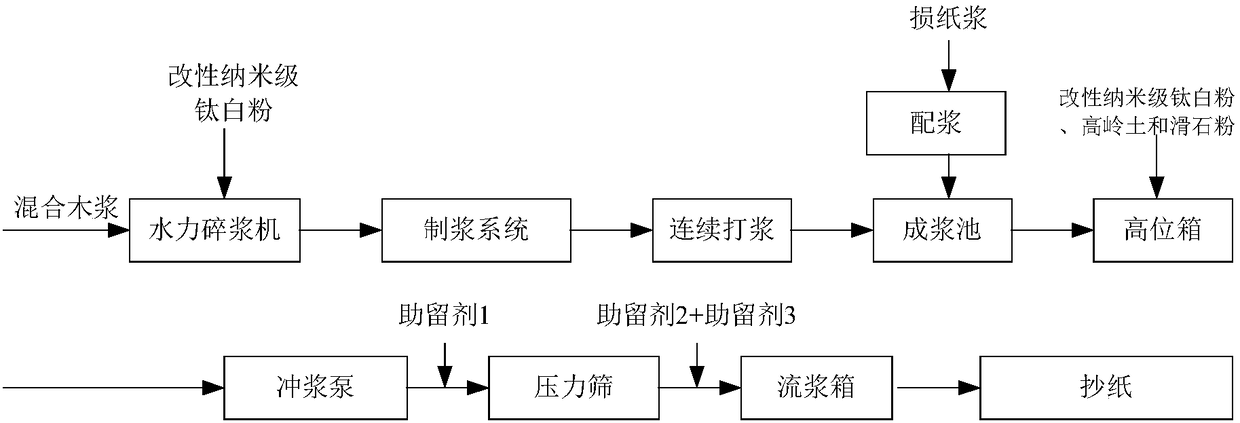

Method used

Image

Examples

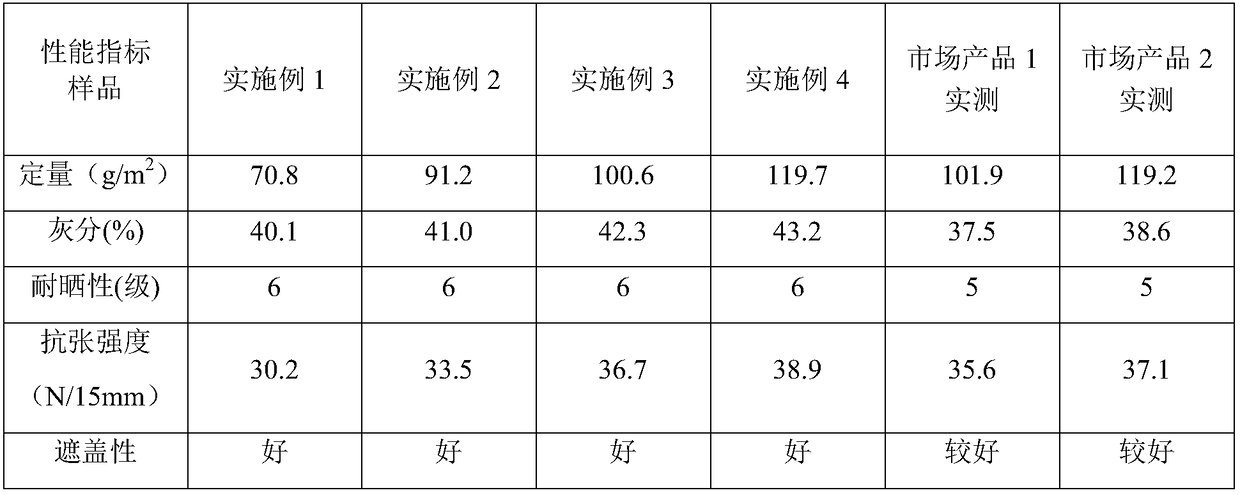

Embodiment 1

[0028] A special decorative base paper for ecological boards in this embodiment is composed of pulp, composite fillers and multi-component retention aids, and the mass-number ratio of the pulp, composite fillers and multi-component retention aids is 1:0.51:0.002 ;

[0029] The pulp is composed of bleached hardwood sulfite pulp, bleached softwood kraft pulp, bleached broadleaf chemical mechanical pulp and broken paper pulp, and the ratio of parts by mass is: bleached hardwood sulfite pulp: bleached softwood pulp Kraft pulp: bleached mechanical pulp: broken pulp = 1: 0.7: 0.2: 0.05; the average fiber length of the bleached broad-leaved wood pulp is 1.0 mm; the broken pulp is recycled in the production process pulp;

[0030] The composite filler is composed of modified nano-scale titanium dioxide, kaolin and talcum powder, and the mass-to-number ratio is: modified nano-scale titanium dioxide: kaolin: talc powder is 1:0.1:0.1. The modifier of the modified nano-titanium dioxide i...

Embodiment 2

[0039] A special decorative base paper for ecological boards in this embodiment is composed of pulp, composite fillers and multi-component retention aids, and the mass-number ratio of the pulp, composite fillers and multi-component retention aids is 1:0.53:0.006 ;

[0040] The pulp is composed of bleached hardwood sulfite pulp, bleached softwood kraft pulp, bleached broadleaf chemical mechanical pulp and broken paper pulp, and the ratio of parts by mass is: bleached hardwood sulfite pulp: bleached softwood pulp Kraft pulp: bleached mechanical pulp: broken pulp = 1: 0.75: 0.25: 0.06; the average fiber length of the bleached broad-leaved wood pulp is 1.5mm; the broken pulp is regenerated from the production process pulp;

[0041] The composite filler is composed of modified nano-scale titanium dioxide, kaolin and talcum powder, and its mass-number ratio is: modified nano-scale titanium dioxide: kaolin: talc powder is 1:0.2:0.2, and the modified nano-titanium The modifying agen...

Embodiment 3

[0050] A special decorative base paper for ecological boards in this embodiment is composed of pulp, composite filler and multi-component retention aid, and the mass-number ratio of pulp, composite filler and multi-component retention aid is 1:0.55:0.01;

[0051] The pulp is composed of bleached hardwood sulfite pulp, bleached softwood kraft pulp, bleached broadleaf chemical mechanical pulp and broken paper pulp, and the ratio of parts by mass is: bleached hardwood sulfite pulp: bleached softwood pulp Kraft pulp: bleached mechanical pulp: broken paper pulp = 1: 0.8: 0.3: 0.08; the average length of the fibers of the bleached broad-leaved wood chemical pulp is 2.0mm; the broken paper pulp is recycled in the production process pulp;

[0052] The composite filler is composed of modified nano-scale titanium dioxide, kaolin and talcum powder, and the mass-to-number ratio is: modified nano-scale titanium dioxide: kaolin: talc powder is 1:0.3:0.3. The modifier of the modified nano-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com