High-cleanliness economical microemulsion metal cutting fluid

A kind of metal cutting fluid, economical technology, applied in the direction of lubricating composition, etc., can solve the problems of reducing the service life of tools and grinding wheels, shortening the service life of cutting fluid, affecting the surface roughness of workpieces, etc., so as to save the amount of raw liquid used and improve processing Effect of precision and surface finish, excellent cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

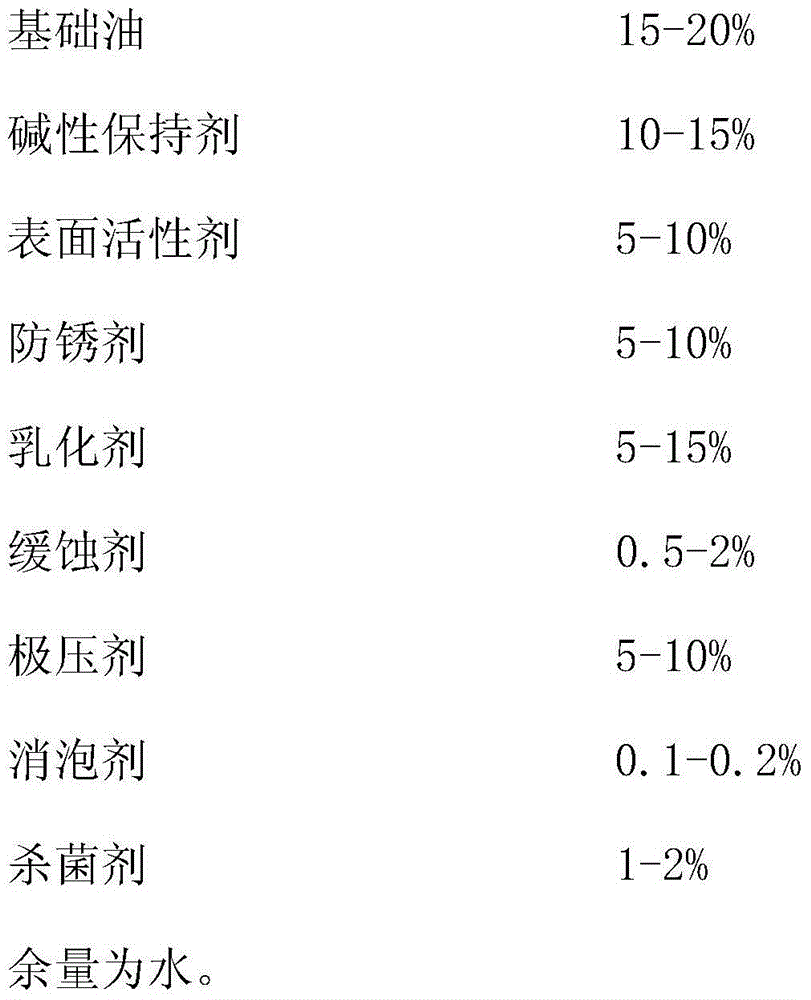

[0023] A highly clean, economical micro-emulsion metal cutting fluid, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0024]

[0025]

[0026] Wherein, the base oil is paraffin base oil; the alkaline retaining agent is one or more of isopropanolamine, triethanolamine, monoethanolamine, 2-amino, 2-methyl propanol, such as isopropanolamine, A mixture of triethanolamine; the surfactant is a mixture of sodium petroleum sulfonate and fatty alcohol polyoxyethylene ether; the antirust agent is one of boric acid, sebacic acid, lauric acid, ammonium sulfonate, boric acid ester and oleic acid A mixture of two or more, such as a mixture of boric acid, lauric acid, and ammonium sulfonate; the emulsifier is one or more of animal oleic acid, vegetable oleic acid, polymerized oleic acid, isomerized cetyl alcohol, and tall oil A mixture of two or more, such as animal oleic acid, vegetable oleic acid, and polymeriz...

Embodiment 2

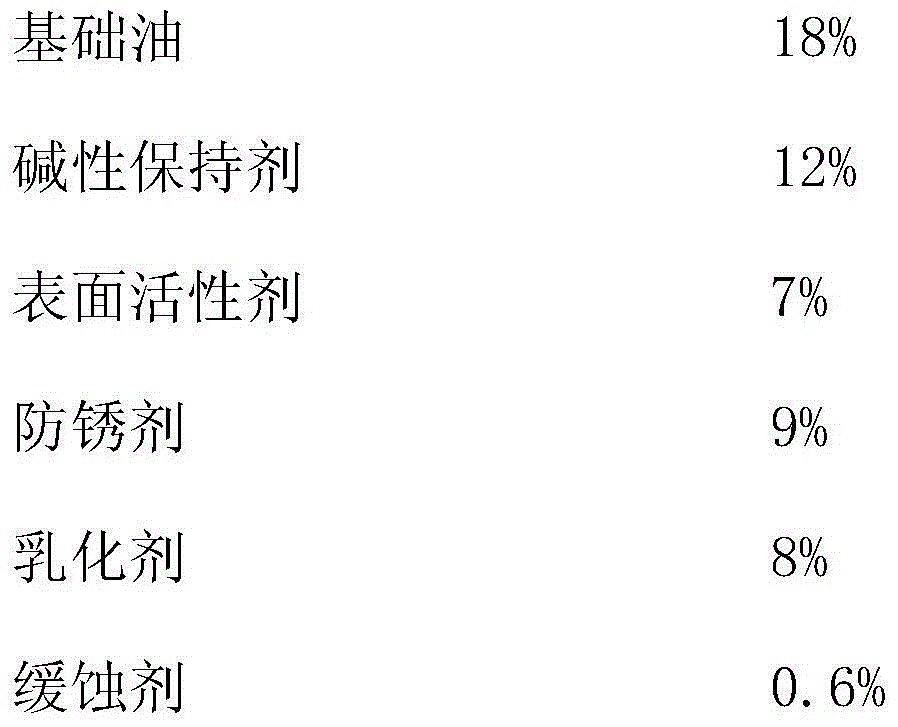

[0028] A highly clean, economical micro-emulsion metal cutting fluid, wherein each raw material component is calculated by weight percentage, and its composition and content are as follows:

[0029]

[0030]

[0031] Among them, the base oil is naphthenic oil; the alkaline retaining agent is a mixture of monoethanolamine, 2-amino, 2-methyl propanol; the surfactant is a mixture of sodium petroleum sulfonate and fatty alcohol polyoxyethylene ether; The rust agent is a mixture of sebacic acid, lauric acid, and oleic acid; the emulsifier is a mixture of vegetable oleic acid, polymerized oleic acid, and tall oil acid; the corrosion inhibitor is methyl benzotriazole; the extreme pressure agent is phosphoric acid ester, A mixture of chlorine-containing polymers; the defoamer is modified dimethylsiloxane; the fungicide is methylisothiazolinone.

Embodiment 3

[0033]

[0034] Among them, the base oil is paraffin oil; the alkaline retaining agent is isopropanolamine; the surfactant is a mixture of sodium petroleum sulfonate and fatty alcohol polyoxyethylene ether; the antirust agent is ammonium sulfonate and borate Mixture; emulsifier is a mixture of isomerized cetyl alcohol and tall oil acid; corrosion inhibitor is phosphoric acid ester; extreme pressure agent is sulfurized fatty acid ester; defoamer is polyether; fungicide is methyl benzoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com