Method for producing environment-friendly regenerated bobbin body paper by using paper mill sludge of newsprint

A technology of papermaking sludge and bobbin base paper, which is applied in the direction of waste addition, secondary cellulose fiber, etc., can solve the problems of energy waste, high cost of raw materials, unfavorable reuse, resource utilization, etc., and achieve the goal of saving clean water resources, Low cost and the effect of reducing water cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

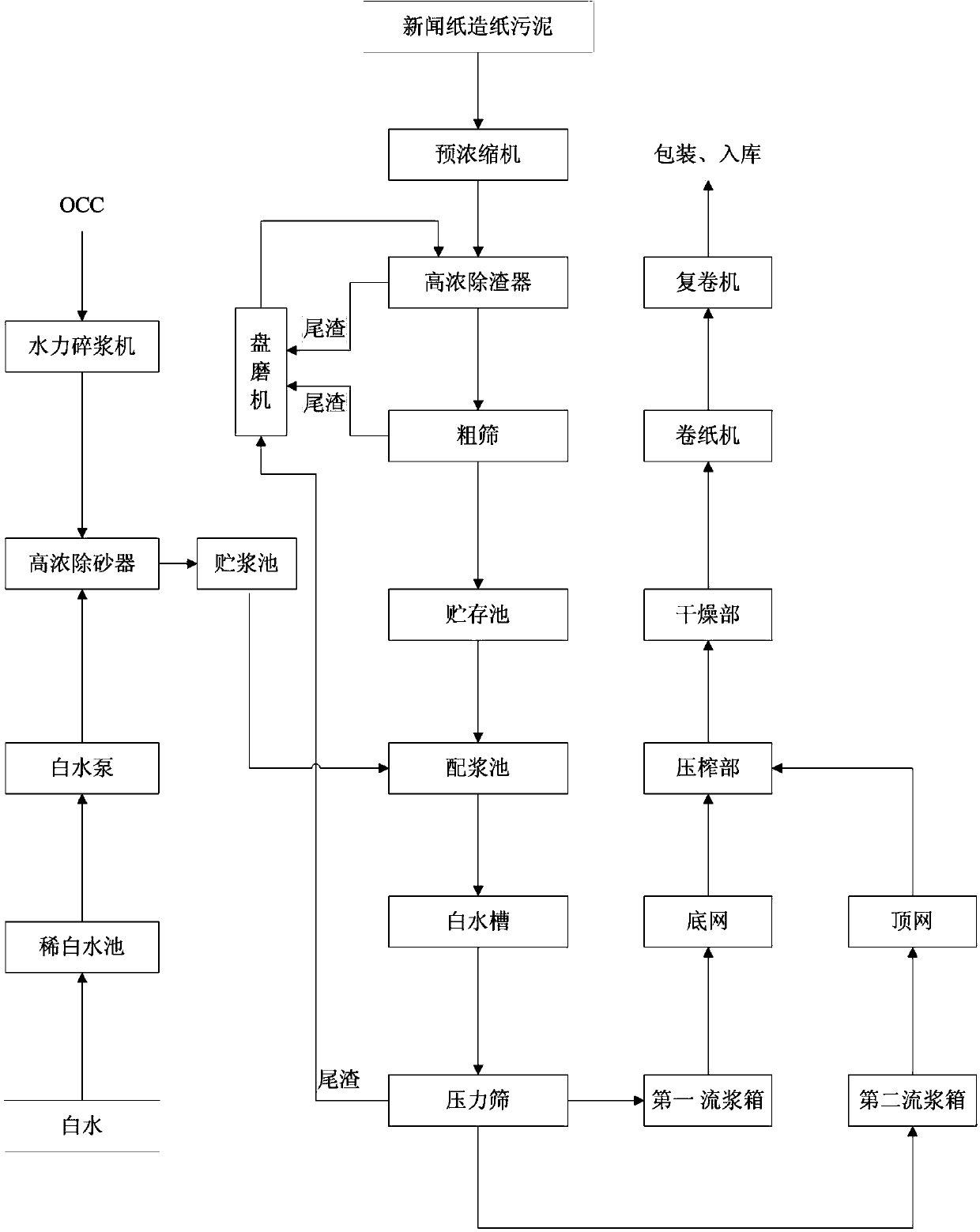

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 Shown, the method that utilizes newsprint papermaking sludge of the present invention to produce environment-friendly regenerated bobbin base paper may further comprise the steps:

[0016] 1) Treatment of newsprint papermaking sludge: Newsprint papermaking sludge is sent to a pre-thickener, and the newsprint papermaking sludge is concentrated to a predetermined concentration through the pre-thickener, and the concentrated newsprint papermaking sludge is sent to a high-concentration slag remover for deslagging. The newsprint papermaking sludge obtained after slag enters the coarse screen for further screening, and the screened newsprint papermaking sludge enters the storage tank; among them, the final control of the process parameters is as follows: the pulp concentration of the high-concentration deslaggi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dryness | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com