Chemi-mechanical pulp manufacturing technology

A chemical-mechanical and pulping technology, applied in pulp bleaching, cellulose pulp post-processing, washing/replacing pulp treatment liquid, etc., can solve the problems of small scale of production capacity, low bleaching efficiency, and high system operating costs, and achieve extrusion Good impregnation effect, improve overall efficiency and reduce energy consumption for refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

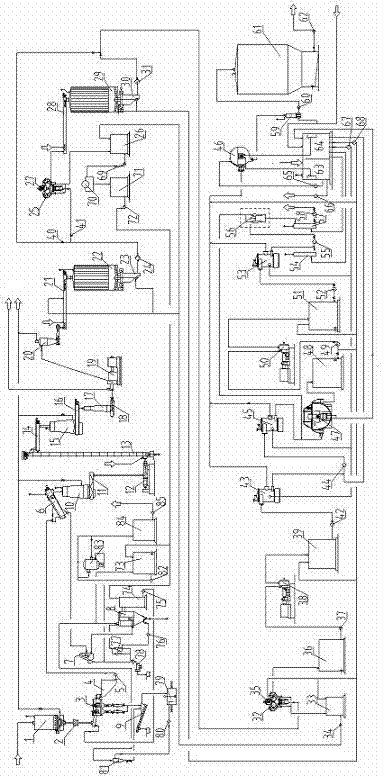

[0071] Examples such as figure 1 As shown, a chemical-mechanical pulping process, which is named "ECMP-Efficient Chemi-mechanical pulp" (ECMP-Efficient Chemi-mechanical pulp) pulping process, includes wood chip washing steps, extrusion impregnation steps, refining, Bleaching and pulp washing steps, screening purification and pulp residue regrinding steps, pulp concentration and storage steps, water recycling steps and chemical use control steps;

[0072] A. Wood chip washing steps are:

[0073] Using the principle of steam condensation and vacuum to make the wood chips further absorb water to increase and balance the moisture of raw materials, and at the same time filter and dehydrate the washed wood chips / water suspensions to achieve the dryness required by subsequent equipment, and perform online purification of the washing water.

[0074] Specifically: the qualified wood chips from the material preparation section enter the wood chip bin 1 and stay for 10-20 minutes, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com