Newsprint for affset print

A technology of offset printing and newsprint, which is applied in papermaking, paper coating, textiles and papermaking, etc. It can solve the problems of easy powder falling, high oil absorption, unsuitability, etc., and achieve the effect of good ink fixation and good opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

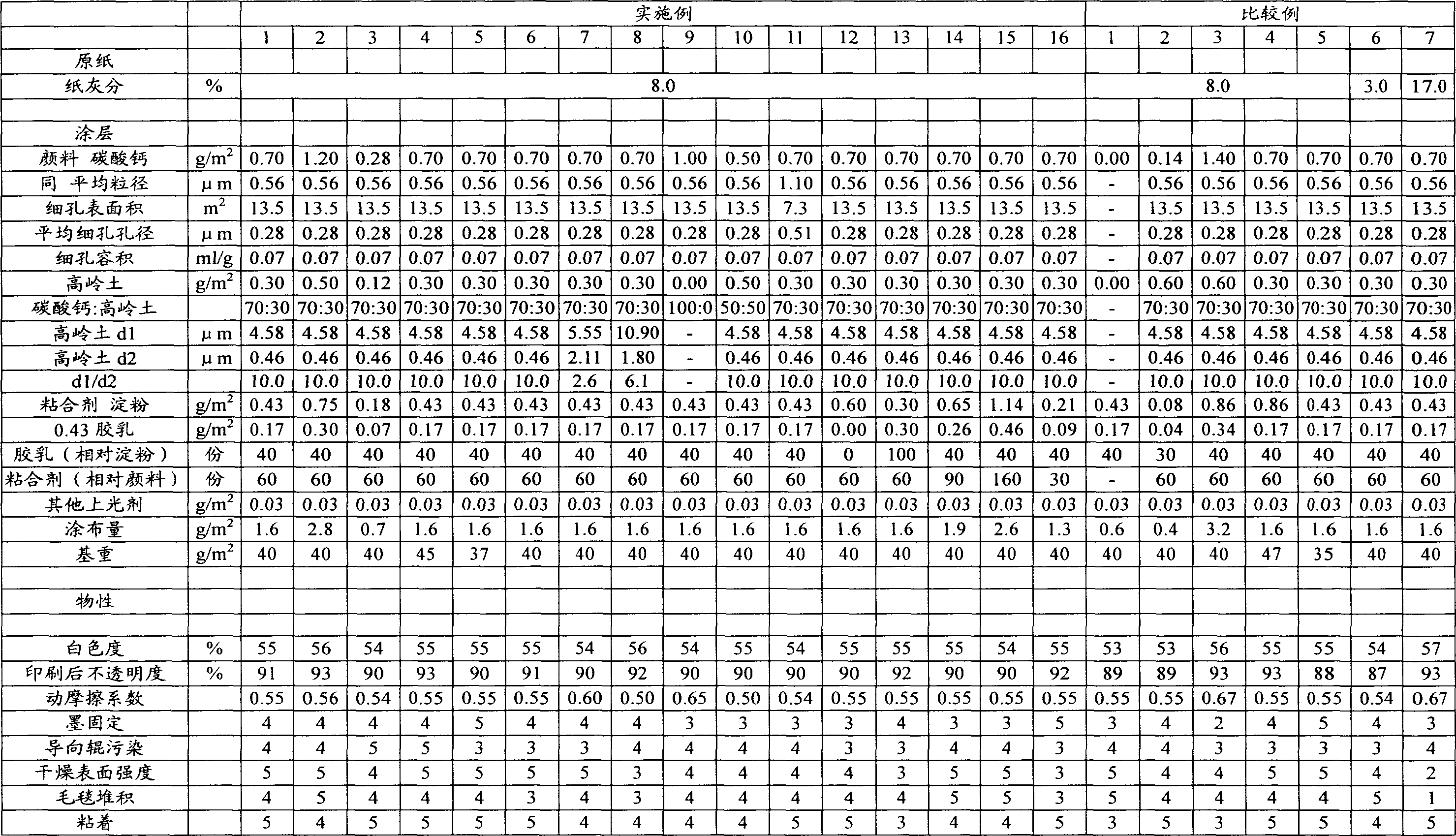

Examples

Embodiment 1

[0122] Base paper: 10 parts of coniferous kraft pulp, 20 parts of preheated mechanical pulp, and 70 parts of deinked waste paper pulp are mixed and macerated, and the degree of freedom is adjusted to 120mlCSF (Canadian standard degree of freedom, below) with a refiner (Refiner). To the raw pulp of CSF), 0.5% of cationized starch (trade name: P3Y, manufactured by PIRAABSTARCH Co., Ltd.) was added to absolute dry pulp, and talc (NTP-2, manufactured by Nippon Talc Co., Ltd.) was added as seasoning 2%, white carbon (self-made) 2%, papermaking pH is adjusted to 5 with alum. The obtained paper stock was made into paper using a paper machine in the twin-wire form (MH specification).

[0123] Coating: As a coating solution, 70 parts of calcium carbonate (A), 30 parts of kaolin (C), 43 parts of oxidized starch (manufactured by Oji Engineering Co., Ltd.), latex (styrene-butadiene copolymer, trade name : T-2635R, manufactured by JSR Co., Ltd., water-dispersible adhesive) 17 parts, surfa...

Embodiment 2

[0129] In the coating process, except that the coating amount of the pigment layer is 2.8g / m 2 Newsprint for offset printing was obtained in the same manner as in Example 1 except for coating.

Embodiment 3

[0131] In the coating process, except that the coating amount of the pigment layer is 0.7g / m 2 Newsprint for offset printing was obtained in the same manner as in Example 1 except for coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com