Automated guided vehicle for rolls of newsprint

A technology for conveying vehicles and paper rolls, applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high energy consumption, heavy lifting platform, difficult maintenance of rolling wheels and lifting unit 240, etc. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

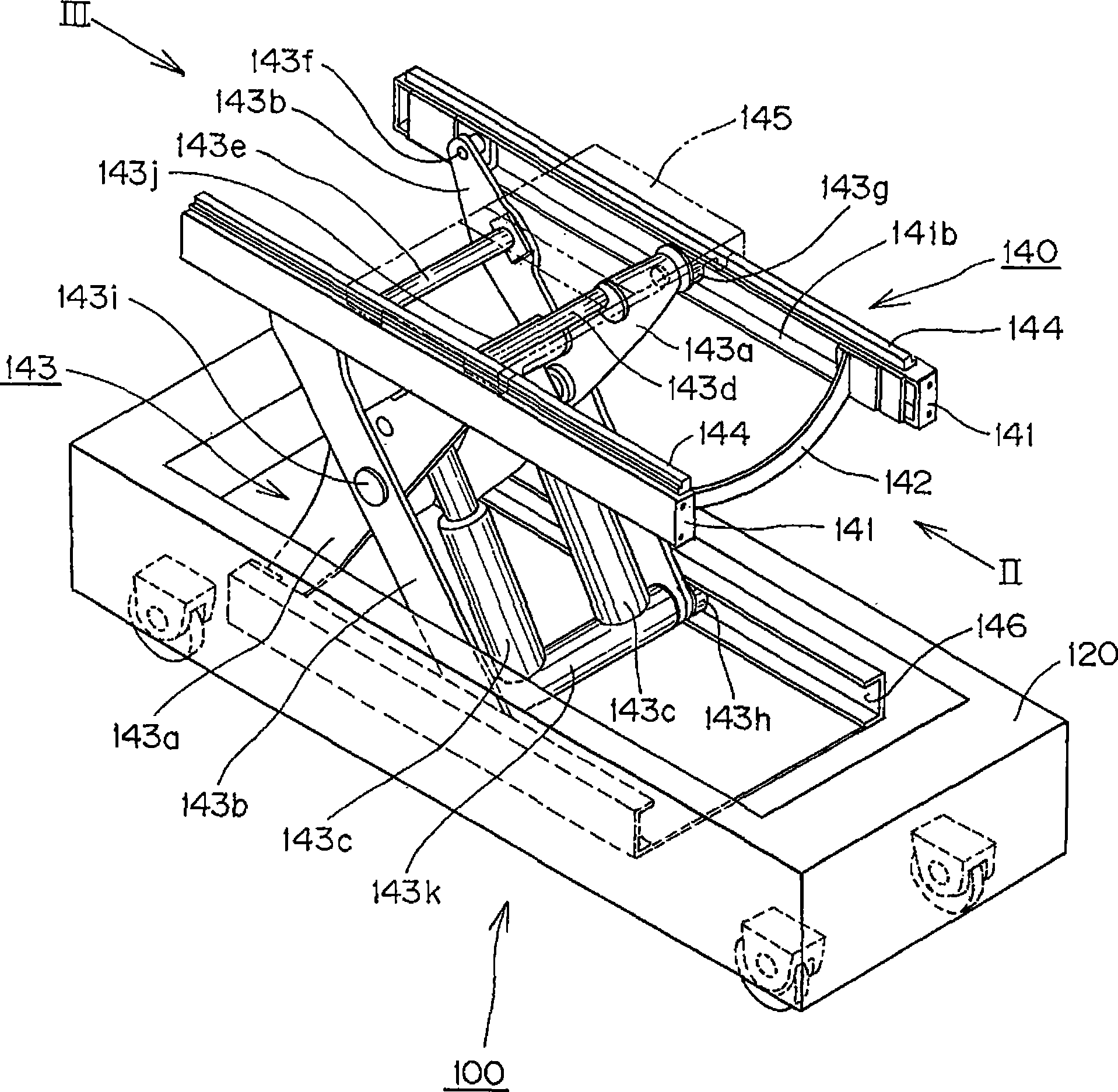

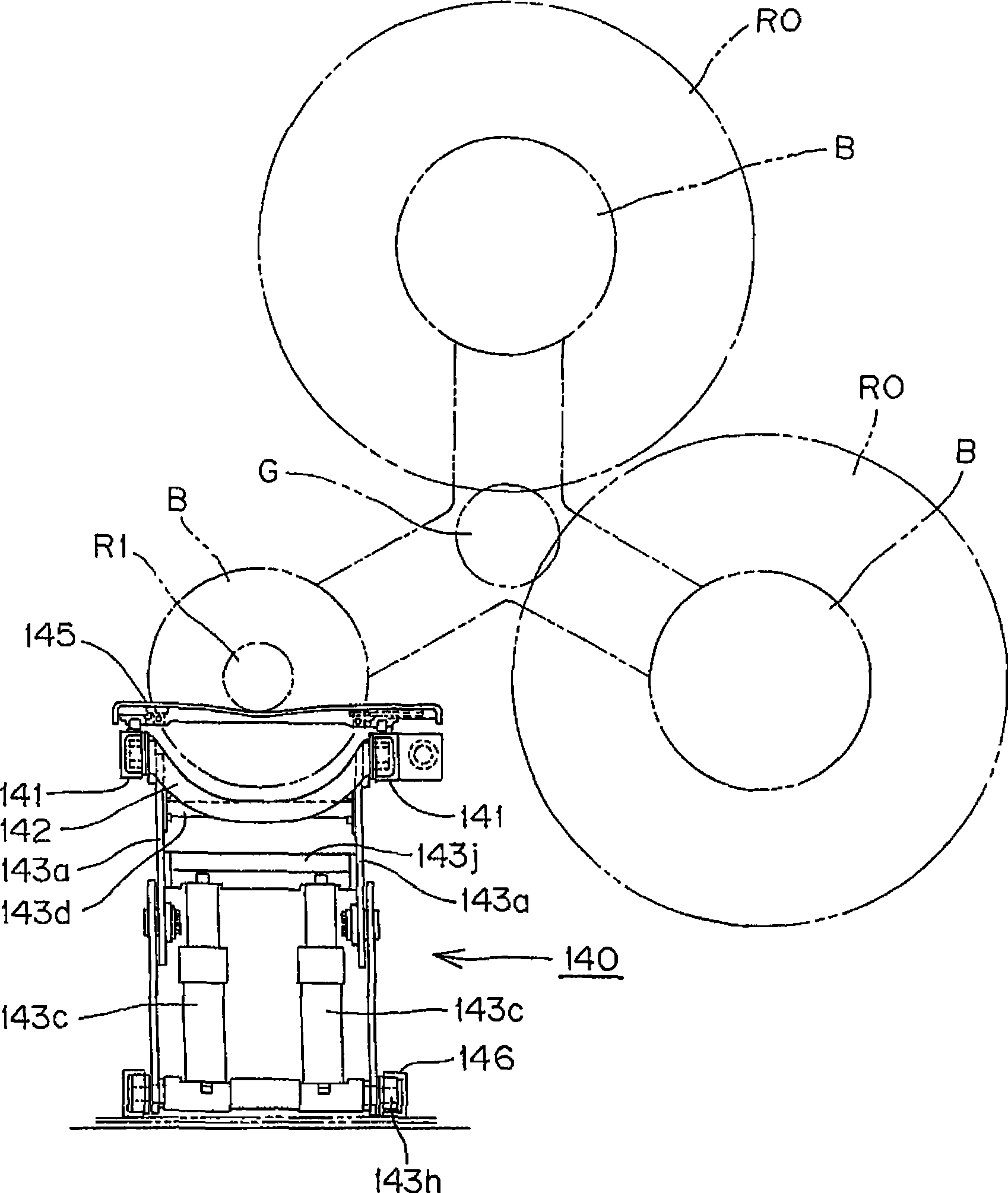

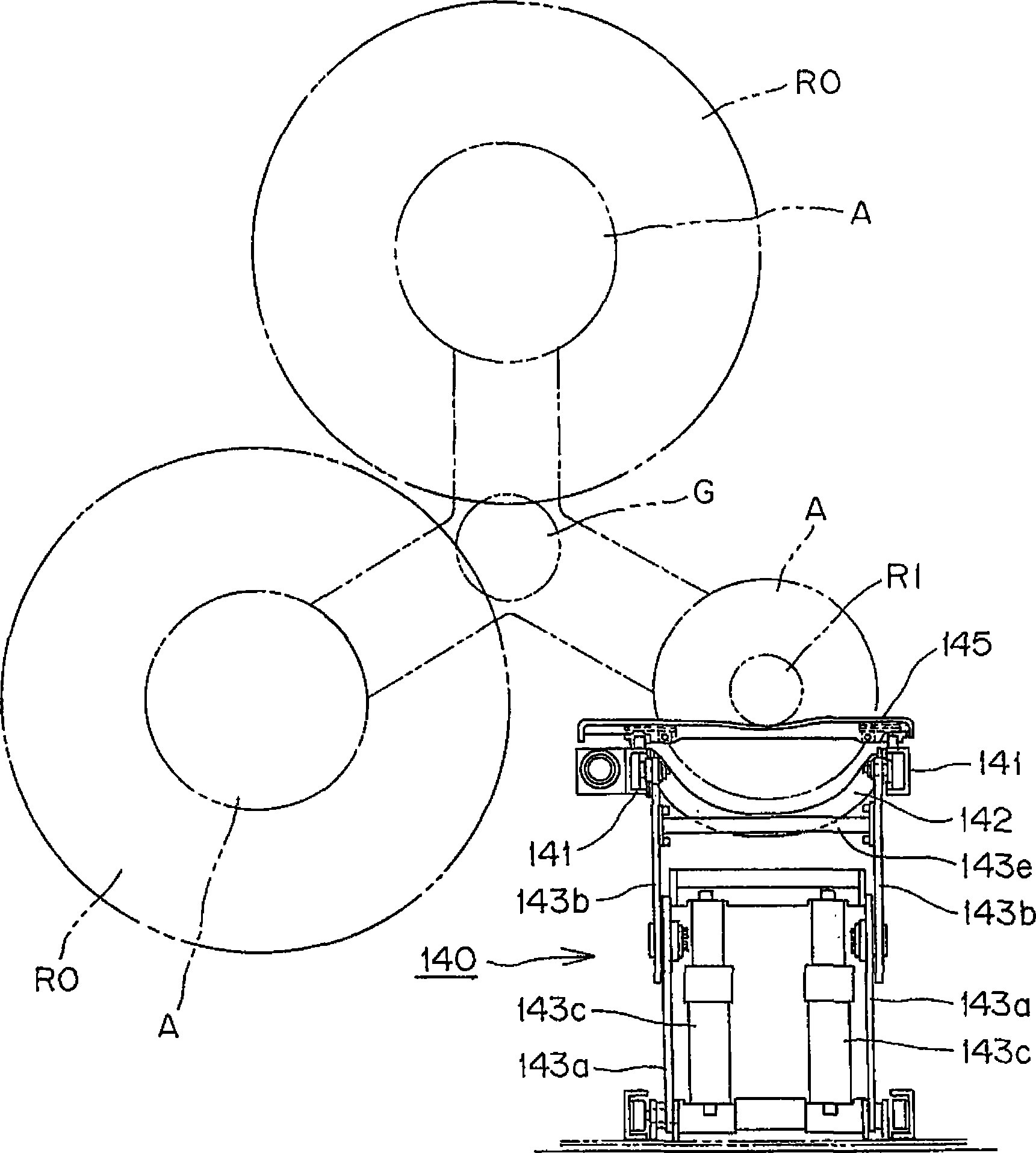

[0032] based on Figure 1 to Figure 6 An example of the present invention will be described. figure 1 It is an overall perspective view of the unmanned transport vehicle of the present invention. figure 2 is seen from the direction of arrow II figure 1 The side view of the relationship between the lifting unit of the unmanned conveyor vehicle and the paper feeding device of the rotary printing press shown, image 3 is seen from arrow III figure 1 The side view of the relationship between the lifting unit of the unmanned conveyor vehicle and the paper feeding device of the rotary printing press shown. in addition, Figure 4 It is a side view when the D-roll newspaper roll R1 in use is to be mounted on the paper feeding device of the rotary printing machine with the left end aligned by the unmanned transport vehicle of the present invention. Figure 5 It is a side view when the D-roll newspaper roll R1 in use has been left-aligned and mounted on the paper feeder of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com