Office waste paper recycling method

A technology of office waste paper and pulp, which is applied in the direction of paper recycling, processing waste paper, recycling technology, etc., can solve the problem that there is no small-scale integrated equipment for office copying waste paper to recycle office paper, the popularity is not high, and the price is not high. Philippines and other issues, to achieve the effect of facilitating promotion and use, protecting the environment and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for recycling office waste paper, comprising the steps of:

[0024] 1) Take a certain amount of office waste paper in the extractor, heat it in a constant temperature water bath at 60°C, and add a solvent for extraction. After the residual solvent in the extracted sample evaporates, adjust the concentration of the slurry to 8%, and add The waste paper is shredded in the mixer, and the shredding time is 45 minutes; during the immersion process of the waste paper, gentle friction can also be generated between the waste paper fibers to improve the shredding effect;

[0025] 2) Add SKHZYE-DPE91 biological enzyme to the crushed pulp for pretreatment before ultrasonic deinking;

[0026] 3) Put the pretreated pulp in an ultrasonic cleaning tank with a small amount of sodium silicate, sodium hydroxide and hydrogen peroxide for ultrasonic treatment for 10 minutes, control the ultrasonic treatment temperature at 40°C, and ultrasonic treatment power of 300W. The frequenc...

Embodiment 2

[0035] A method for recycling office waste paper, comprising the steps of:

[0036] 1) Take a certain amount of office waste paper in the extractor, heat it in a constant temperature water bath at 60°C, and add a solvent for extraction. After the residual solvent in the extracted sample evaporates, adjust the concentration of the slurry to 8%, and add The waste paper is shredded in the mixer, and the shredding time is 45 minutes; during the immersion process of the waste paper, gentle friction can also be generated between the waste paper fibers to improve the shredding effect;

[0037] 2) Add SKHZYE-DPE91 biological enzyme to the crushed pulp for pretreatment before ultrasonic deinking;

[0038] 3) Put the pretreated pulp in an ultrasonic cleaning tank with a small amount of sodium silicate, sodium hydroxide and hydrogen peroxide for ultrasonic treatment for 10 minutes, control the ultrasonic treatment temperature at 40°C, and ultrasonic treatment power of 300W. The frequenc...

Embodiment 3

[0047] Through the integrated device of the present invention, it can enter group office places such as schools and enterprises, and it can be made by selecting the equipment in the following table:

[0048] equipment parts

Amount (yuan)

pulper

3000

Concentration and screening device

300

Refining device

200

Detecting the refining device

100

Ultrasonic deinking device

3000

Ozone generator

60

Metering device

100

Pulp online device

100

Press drying device

1000

other devices

1000

total

8760

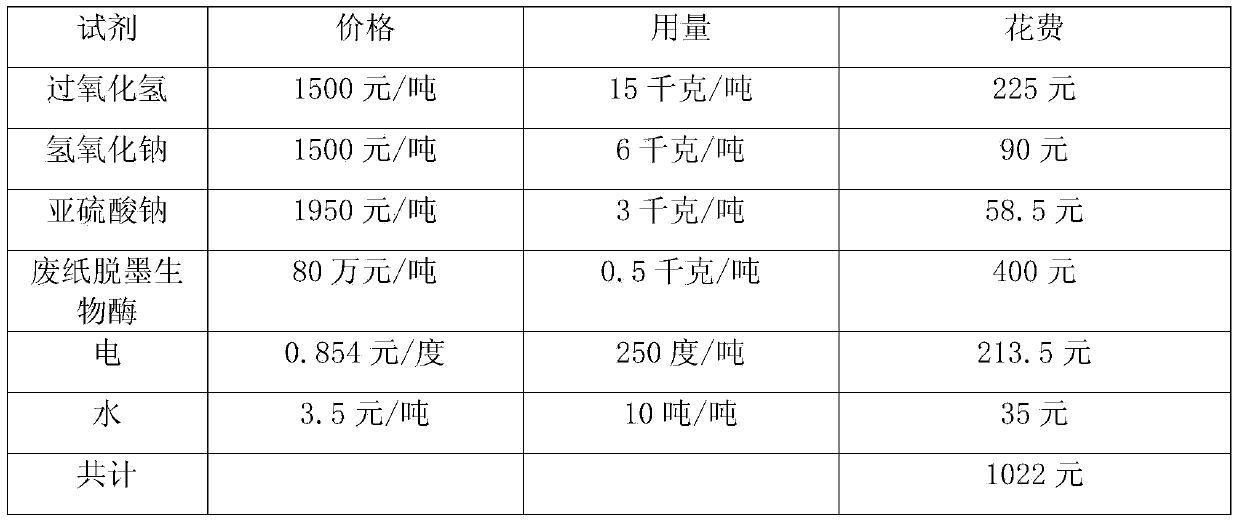

[0049] The price of using these equipment to make paper is as follows:

[0050]

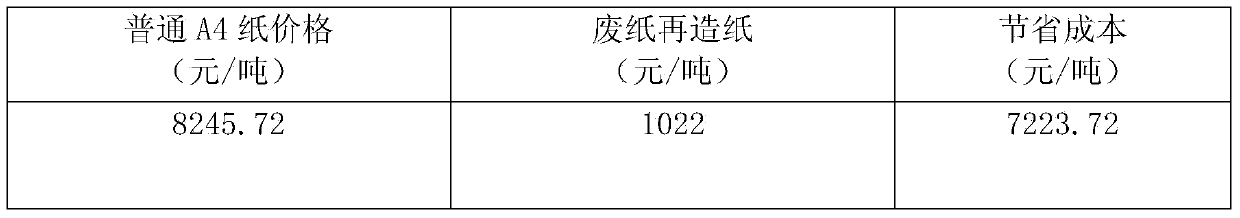

[0051] Use the inventive method to utilize these equipment remanufactured papers and common A4 paper price comparison:

[0052]

[0053] Ordinary paper mills produce office paper = raw wood cost + labor cost + high profit + waste water treatment cost + water and electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com