AIP (Aluminum Isopropoxide) type nonionic surfactant as well as preparation method and application thereof

A non-ionic surface and active agent technology, applied in chemical paint/ink remover, coating, organic chemistry, etc., can solve the problem that the deinking agent cannot meet the production of high-grade recycled paper, and achieve good application prospects and whiteness High, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

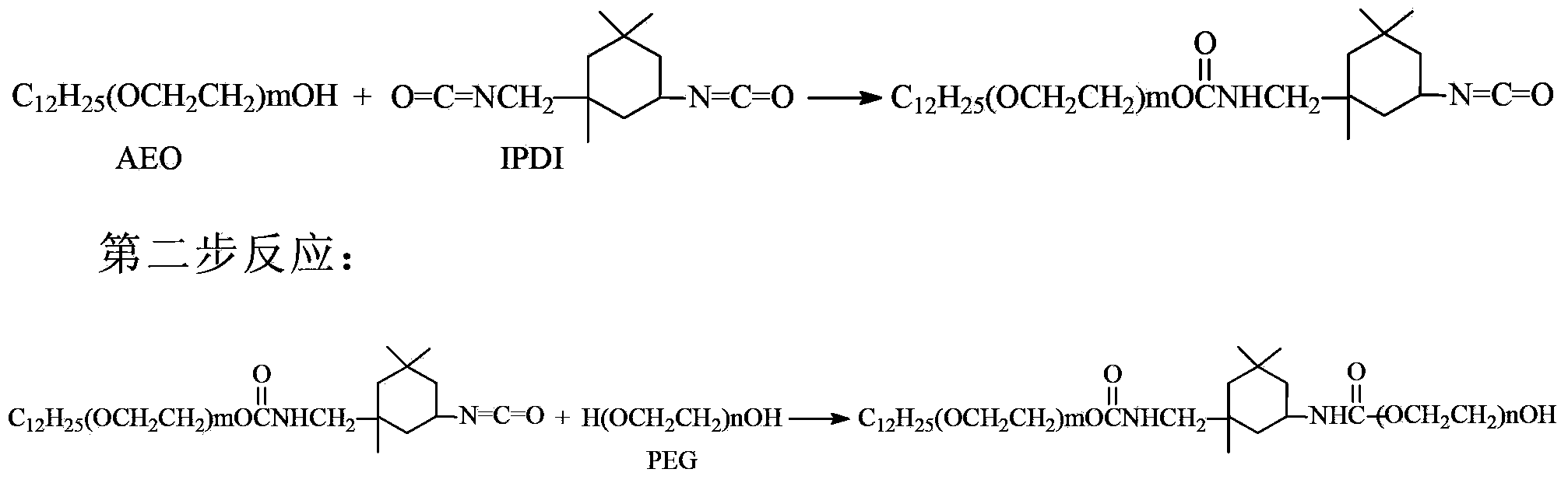

[0032] 1) Add 1 mol of isophorone diisocyanate (IPDI) into the reactor and heat to 50°C at a stirring speed of 250r / min;

[0033] 2) Then, at a stirring speed of 500r / min, slowly drop 1mol of lauryl polyoxyethylene ether-3 (AEO-3) into the reactor at a dropping speed of 15d / min, and continue to stir and keep warm for 60 minutes after the dropping;

[0034] 3) Add 1mol PEG-200 into the reactor quickly within 3s at a stirring speed of 250r / min, continue the reaction at 60°C for 90min until the end of the reaction, and then cool down to room temperature to obtain AIP-type non- ionic surfactant. The AIP type nonionic surfactant prepared in Example 1 is used alone as a deinking agent for waste paper deinking, and is denoted as AIP-1 (m=3, n=4 in the structural formula).

Embodiment 2

[0036] 1) Add 1mol of isophorone diisocyanate (IPDI) into the reactor and heat to 50°C at a stirring speed of 200r / min;

[0037] 2) Then, at a stirring speed of 400r / min, slowly drop 1mol of lauryl polyoxyethylene ether-3 (AEO-3) into the reactor at a dropping speed of 10d / min, and continue to stir and keep warm for 60 minutes after the dropping;

[0038] 3) Add 1 mol of PEG-400 into the reactor quickly within 5s at a stirring speed of 200r / min, continue to react at 70°C for 105min until the end of the reaction, and then cool down to room temperature to obtain AIP-type non- ionic surfactant. The AIP type nonionic surfactant prepared in Example 2 is used alone as a deinking agent for waste paper deinking, and is denoted as AIP-2 (m=3, n=9 in the structural formula).

Embodiment 3

[0040] 1) Add 1 mol of isophorone diisocyanate (IPDI) into the reactor and heat to 50°C at a stirring speed of 250r / min;

[0041] 2) Then, at a stirring speed of 500r / min, slowly drop 1mol of lauryl polyoxyethylene ether-3 (AEO-3) into the reactor at a dropping speed of 15d / min, and continue to stir and keep warm for 60 minutes after the dropping;

[0042] 3) Add 1mol PEG-600 into the reactor quickly within 3s at a stirring speed of 250r / min, continue the reaction at 80°C for 120min until the end of the reaction, and then cool down to room temperature to obtain AIP-type non- ionic surfactant. The AIP type nonionic surfactant prepared in Example 3 is used alone as a deinking agent for waste paper deinking, and is denoted as AIP-3 (m=3, n=13 in the structural formula).

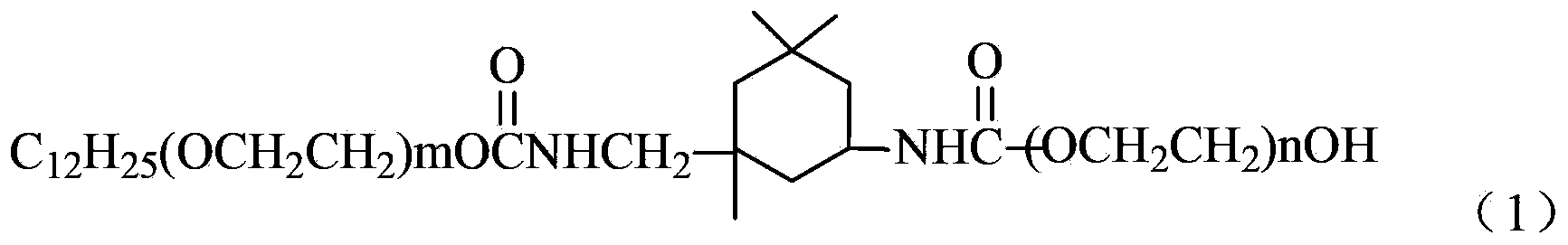

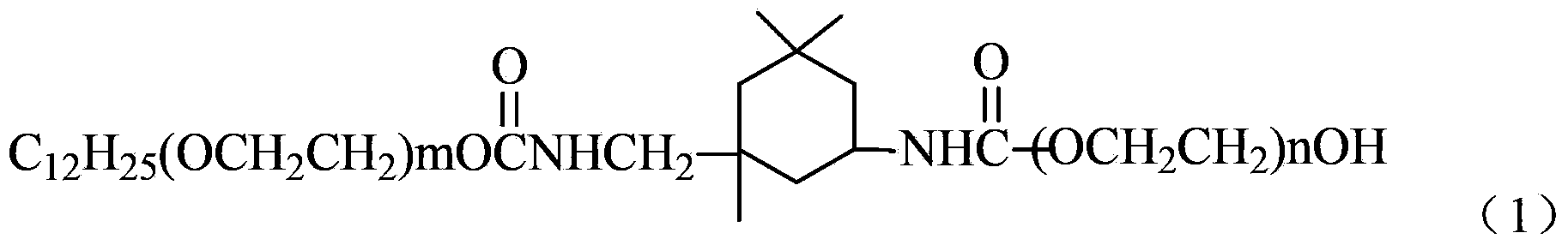

[0043] The molecular structure of AIP-3 is as follows:

[0044]

[0045] Next, AIP-3 was analyzed by IR and 1H NMR.

[0046] 1. IR analysis

[0047] By performing IR analysis on the target product AIP-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com