Process for improving dry strength and drainage of paper and paperboard

a technology of dry strength and drainage, applied in the field of manufacturing process of paper, paperboard, corrugated products, can solve the problems of no longer being usable glyoxylated polymer, affecting the dry strength of paper and paperboard, and suffering noticeable loss of efficiency, so as to improve the dry strength of the resulting paper product, improve the drainage effect, and improve the effect of drainag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

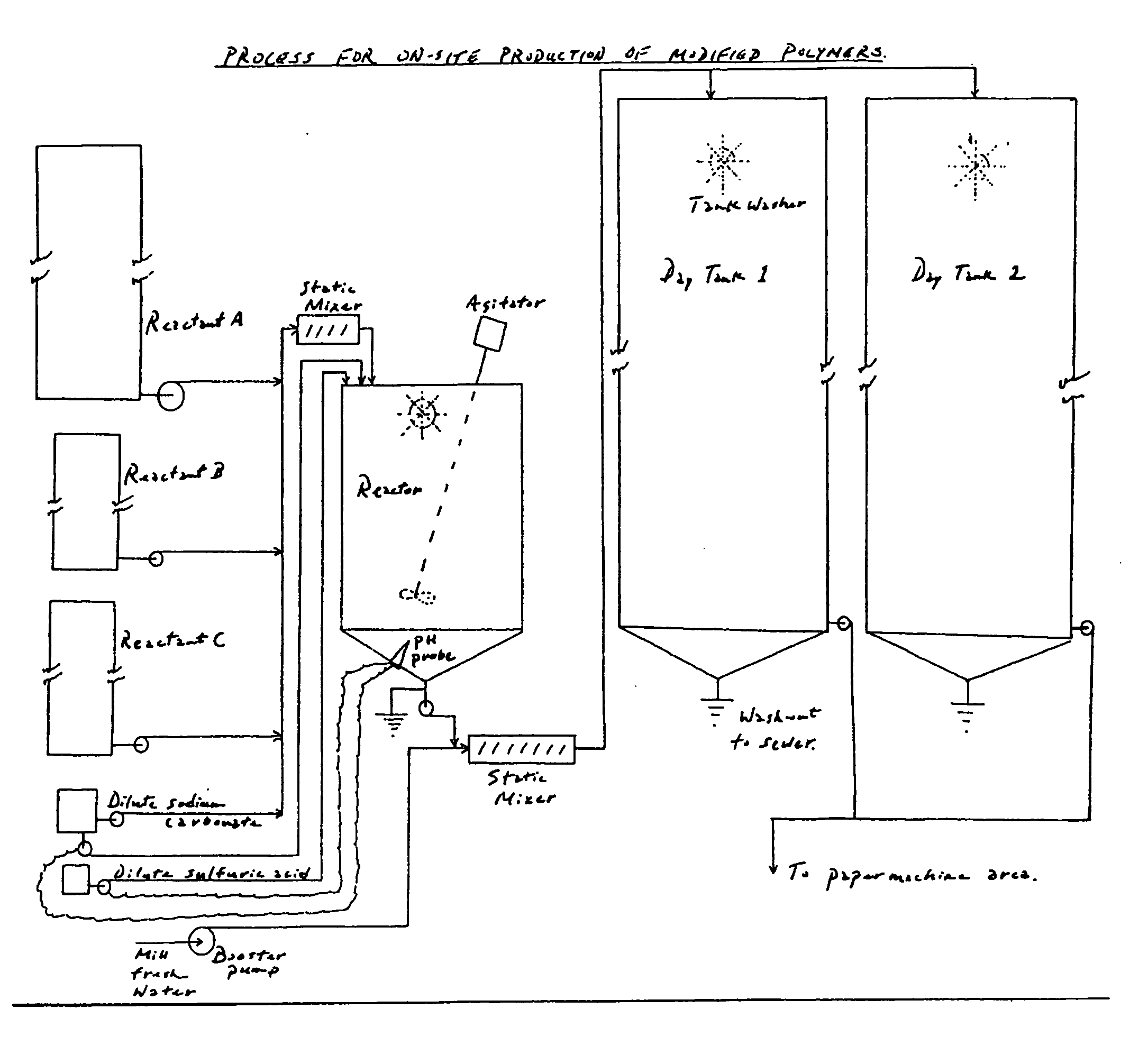

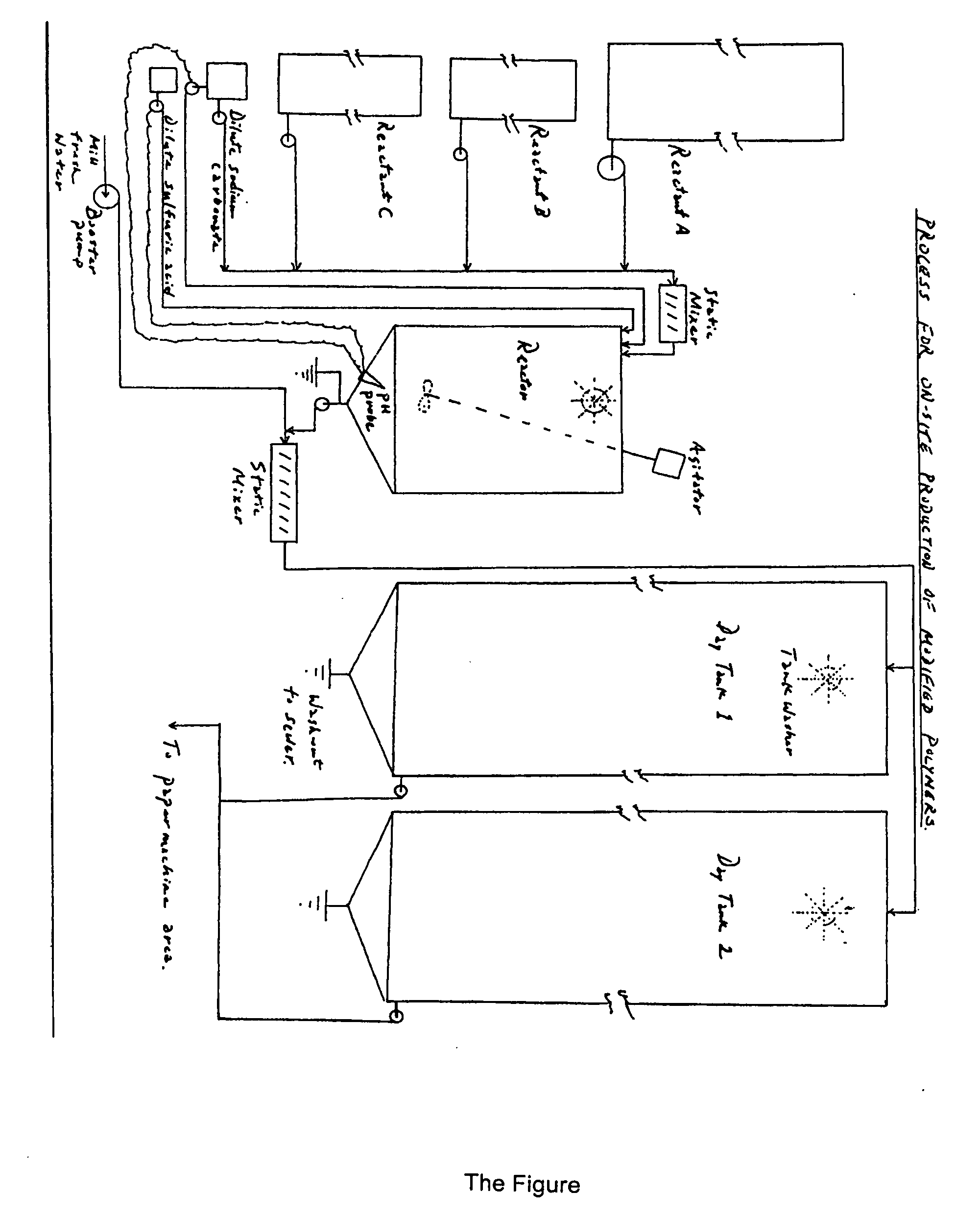

Image

Examples

example 1

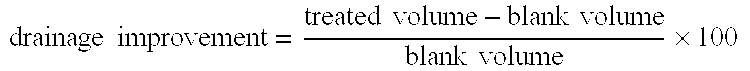

[0023] The effect of gyloxylation on polyacrylamides with varying chain lengths was determined with respect to drainage properties of a paper furnish. The laboratory conditions utilized are representative of a glyoxylation process that may be used on site in a paper mill. The following procedures were used and the results are set forth below.

[0024] Three types of polyacrylamide polymers supplied by Aquaserv, Memphis, Tenn., were selected as referenced in Table 1 below. As noted, samples PCV 005 and PCV 015 are nonionic polymers while the PCV 105 polymer has a 10% cationic charge. The polymers used were prepared using dry powders which were dispersed in deionized water at a 1.7% solids concentration. Thereafter, glyoxal supplied by Noveon, Charlotte, N.C., at a 40% solids concentration was slowly added to the polymer solution while stirring to produce a 25:75 glyoxal to polymer ratio, on a solids basis, for each reactant. The resulting solution was adjusted to a pH of between 7.8 to...

example 2

[0033] The ability of freshly glyoxylated polymers to improve drainage properties of a commercial paper furnish having a clean, open water system was also evaluated. The polymer used to evaluate drainage improvements was a copolymer consisting of a 93 mol percent of dimethyldiallyl ammonium chloride (DADMAC) and a 7 mol percent of polyacrylamide. This copolymer was obtained in an aqueous solution, therefore, it did not require dispersion in water. The glyoxylation process used was otherwise identical to that described in Example 1.

[0034] The paper furnish used was obtained from the headbox of a commercial paper machine making kraft multi-wall bag paper material. The furnish composition was a mixture of 80% unbleached, refined virgin kraft Southern Pine pulp blended with 20% old corrugated containers.

[0035] The furnish was separated into four samples as set forth in Table 3. A portion of the furnish was introduced into a Britt jar at a propeller rotation of 800 rpm, and using a scr...

example 3

[0038] The effect of the copolymer charge on drainage and floc formation was also evaluated using glyoxylated copolymers. As set forth in Table 4, the identified copolymers were used as the starting material and obtained in a liquid form. Glyoxal was added to the copolymer to achieve a 15:85 glyoxal to polymer ratio. The solution was adjusted to a pH of between 7.8 to 8.0 using dilute sodium hydroxide as described in Example 1 above. The glyoxylated copolymers were used at a level equivalent to 5 pounds of glyoxylated polymer per ton of fiber, though it is believed that a useful concentration of 3 to 5 pounds of glyoxylated polymer per ton of fiber is a useful range.

TABLE 4Polymer Identification% Polyacrylamide% DADMACCPC 1070793PC 60505050PC 60109010

[0039] The paper furnish was prepared in a laboratory using defiberized paper stocks of 98% old corrugated container and 2% old newsprint. The drainage test procedures set forth in Example 1 were used and the results set forth below i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com