Device and method for producing cardboard paper by utilizing paper mill sludge and waste paper

A papermaking sludge and production box technology, which is applied in textiles and papermaking, recycling technology, paper, etc., can solve the problems of large land occupation, waste of resources, and secondary pollution of the environment, so as to reduce secondary pollution and save papermaking raw materials , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

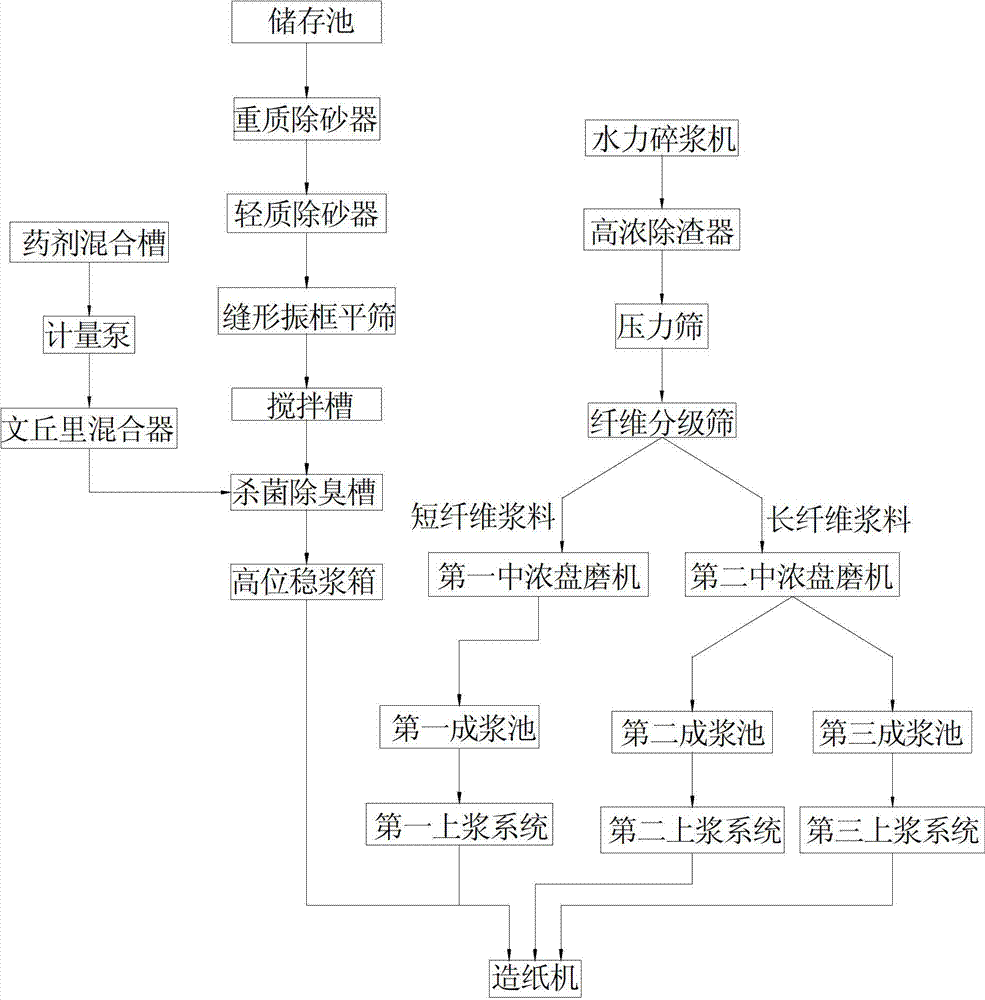

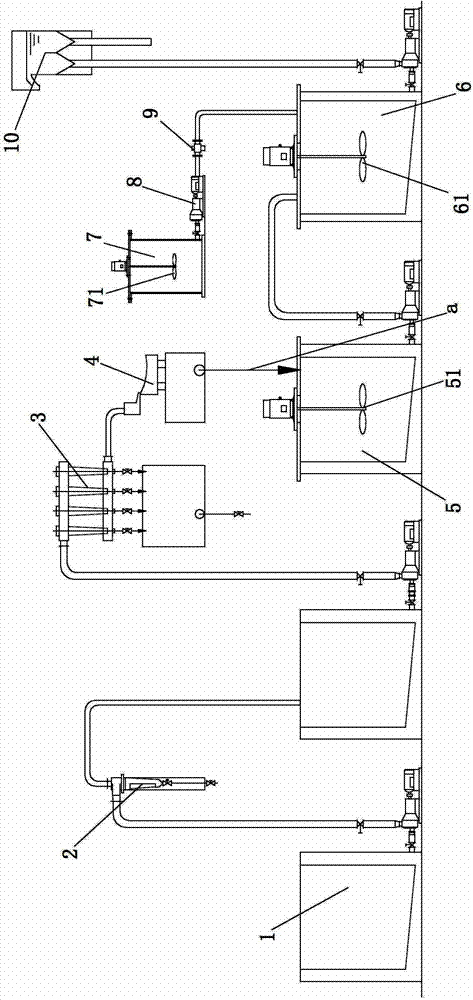

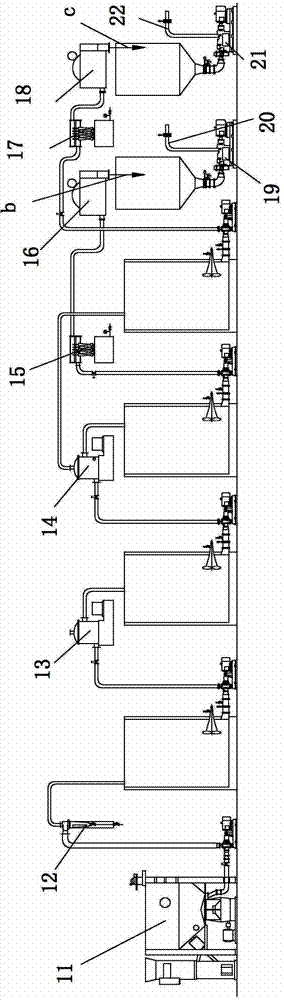

[0028] like Figure 1 to Figure 3 A device for producing containerboard using papermaking sludge and waste paper is shown, which is characterized in that it includes a waste paper pulping system, a sterilization and deodorization system, and a storage tank 1 connected in sequence, a heavy slag remover 2, a light Quality slag remover 3, vibrating frame flat screen 4, stirring tank 5, sterilizing and deodorizing tank 6 and pulp stabilization box 10; the sterilizing and deodorizing tank 6 is connected with the sterilizing and deodorizing system;

[0029] It also includes the first pulping tank, the first pulping system, the second pulping tank, the second pulping system, the third pulping tank, the third pulping system and the paper machine, and the waste paper pulping system passes through the first pulping tank The tank is connected to the first sizing system, and the first sizing system and the stock stabilization box 10 are connected to the paper machine at the same time; the...

Embodiment 2

[0047] The device and method for producing containerboard by utilizing papermaking sludge and waste paper are the same as in Example 1 except for the following features: when the pulp is mixed with short fiber pulp in the step D, the amount of pulp added is 3% of the total mass %.

[0048] The physical properties of the boxboard produced according to this embodiment are: quantitatively 180g / m 2 ;Burst resistance index is 2.1Kpa m 2 / g; the ring pressure index is 6.1N·m / g; the folding endurance is 65 times.

Embodiment 3

[0050] The device and method for producing containerboard paper utilizing papermaking sludge and waste paper are the same as in Example 1 except for the following features: when the pulp is mixed with the short fiber slurry in the step D, the amount of pulp added is 10% of the total mass %.

[0051] The physical properties of the boxboard produced according to this embodiment are: quantitatively 180g / m 2 ;Burst resistance index is 1.8Kpa m 2 / g; the ring pressure index is 5.5N·m / g; the folding endurance is 57 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com