Part service life prediction method comprehensively considering fatigue strength influence factors

A fatigue strength factor and fatigue strength technology, applied in the field of fatigue strength, can solve the problem of difficulty in obtaining size coefficient and surface coefficient, and achieve the effect of reducing design cost and time and simplifying the design process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is illustrated in conjunction with the accompanying drawings.

[0038] The present invention is further illustrated by performing life prediction on a cyclically loaded complex helical spring.

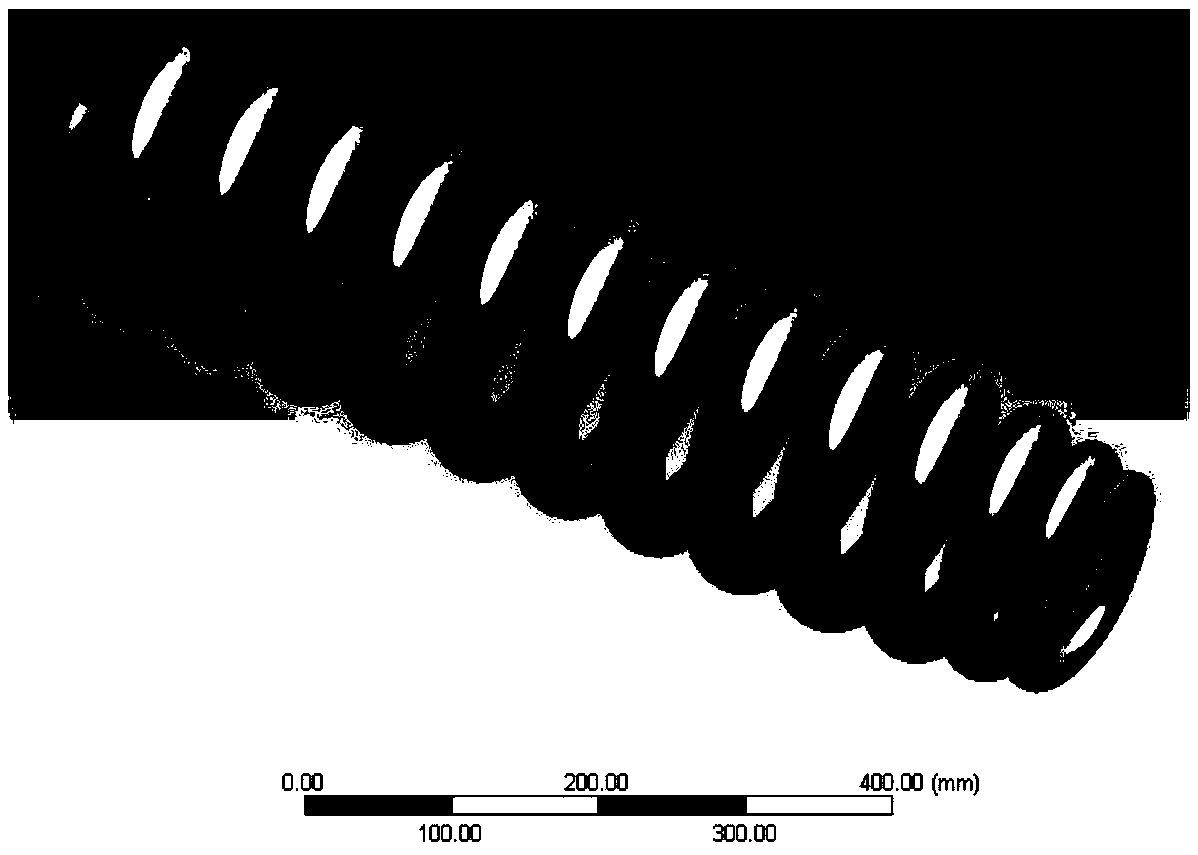

[0039] The geometry of the helical spring is as figure 1 As shown, the material is 60Si2CrVA.

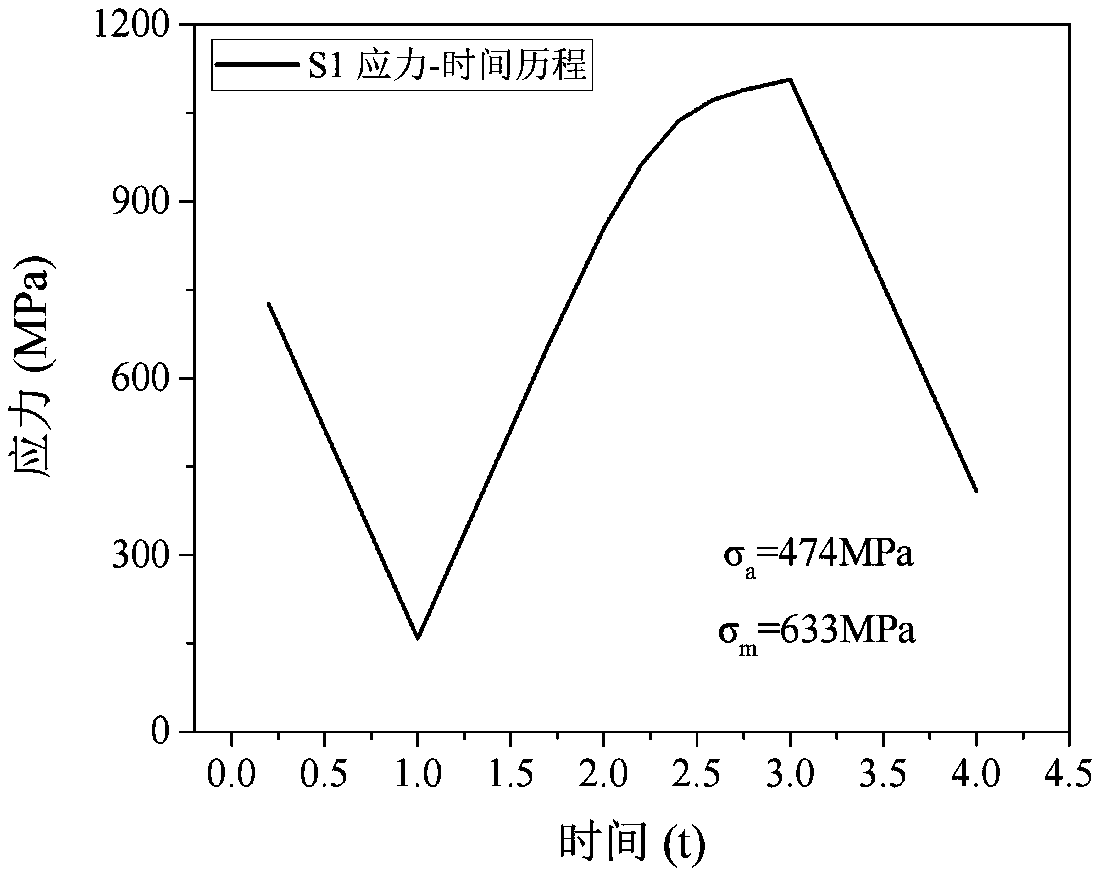

[0040] The loading parameters and fatigue life of the bench fatigue test of the coil spring are shown in Table 1.

[0041] Table 1 Loading parameters and fatigue life of bench fatigue test

[0042]

[0043] A component life prediction method that comprehensively considers factors affecting fatigue strength, characterized in that: the implementation steps of the method are as follows:

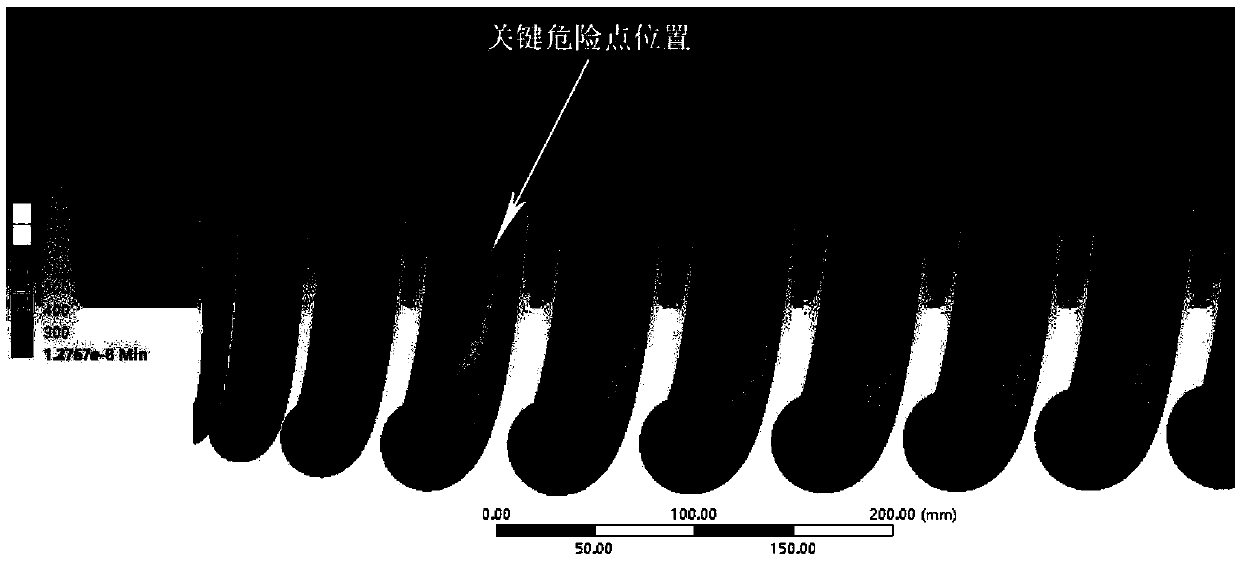

[0044] Step (1): Use the finite element method to conduct a static analysis of the component structure to determine the location of the key dangerous point where the component is weak;

[0045] A compressive displacement load of 86 mm is applied to the coil spring, and its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com