Recycled asphalt concrete material for guaranteeing low-temperature performance and design method thereof

A technology of recycled asphalt and low-temperature performance, which is applied in the field of civil engineering, can solve the problems that limit the development of asphalt concrete recycling technology, poor low-temperature performance, and large material variability, and achieve simple and effective test and calculation methods, small material performance variation, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

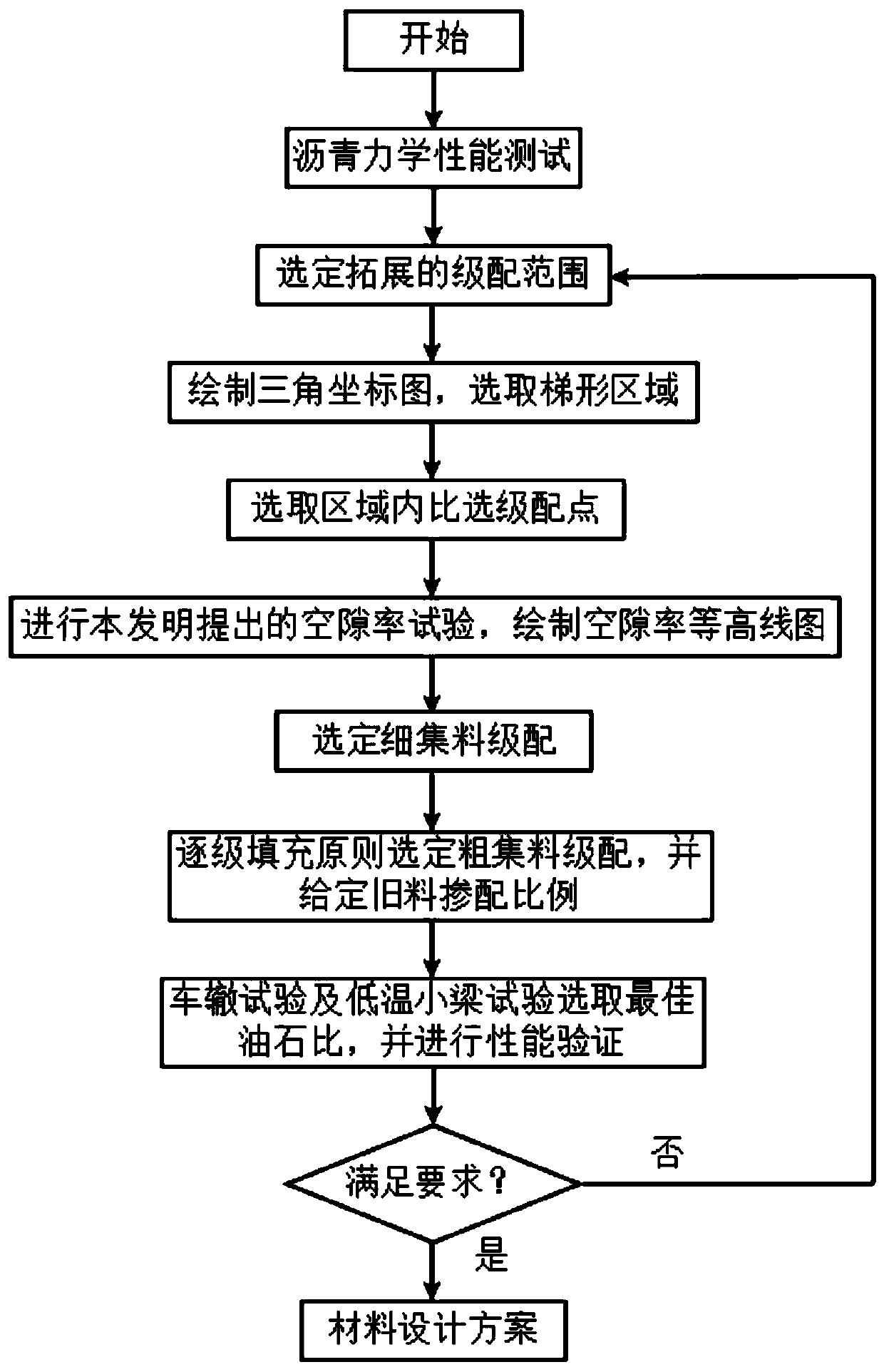

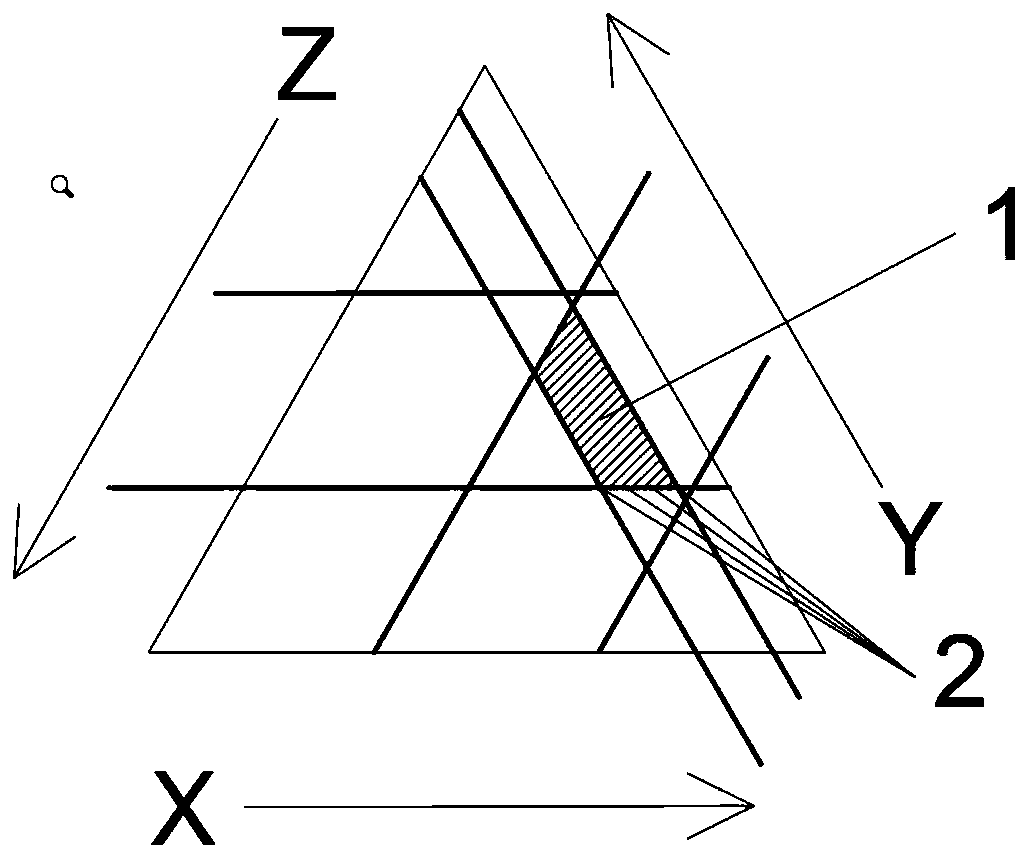

Method used

Image

Examples

example

[0045] The recycled asphalt concrete is designed according to the design method process described in the present invention, and a group of comparison tests are designed according to the median value of AC20 using all new materials, wherein AC20 is 4.0% according to the optimum asphalt ratio, and the recycled asphalt concrete is according to the materials described in the present invention The weight ratio of each material obtained by the design method is as follows.

[0046] Aggregate 56.8%;

[0047] Old material 35%;

[0048] No. 70 asphalt 4.2%;

[0049] Mineral powder 4%;

[0050] The gradation of the aggregate and the old material under the standard sieve size is shown in the table below:

[0051]

[0052] From low temperature performance, high temperature performance, three aspects of water stability performance, the recycled asphalt concrete designed by the present invention is compared with the AC20 gradation new material concrete obtained by the traditional Marsh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com