Simulation part load conversion method based on local actually measured strain at crack tip of actual structural part of airplane

A crack tip, measured strain technology, used in measuring devices, railway vehicle testing, instruments, etc., can solve problems such as tediousness and complex stress on actual structural parts, and achieve the effect of accurate computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

[0031] The present invention further illustrates the present invention by measuring the strain of the actual structural part of the aircraft and transforming the load of the simulated part,

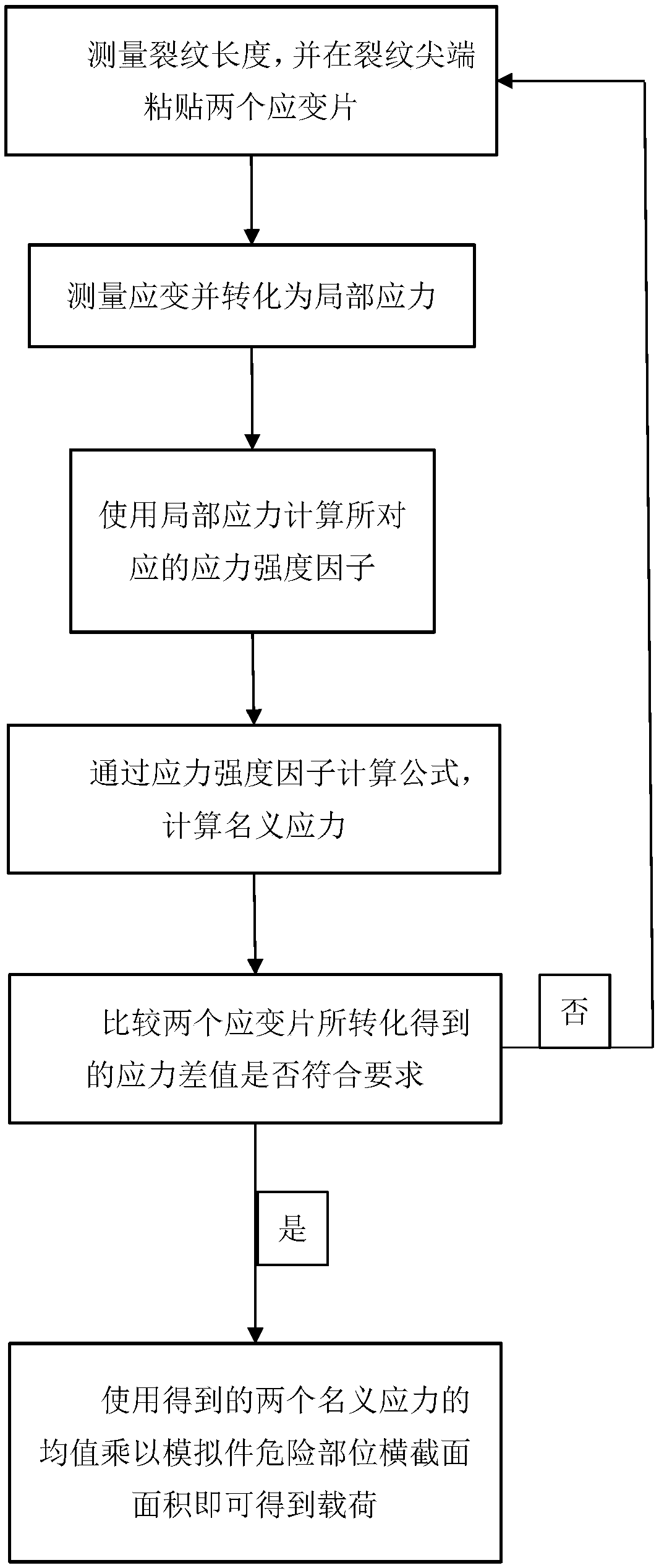

[0032] A load conversion method for simulated parts based on the local measured strain at the crack tip of an actual aircraft structural part. The specific calculation method is as follows:

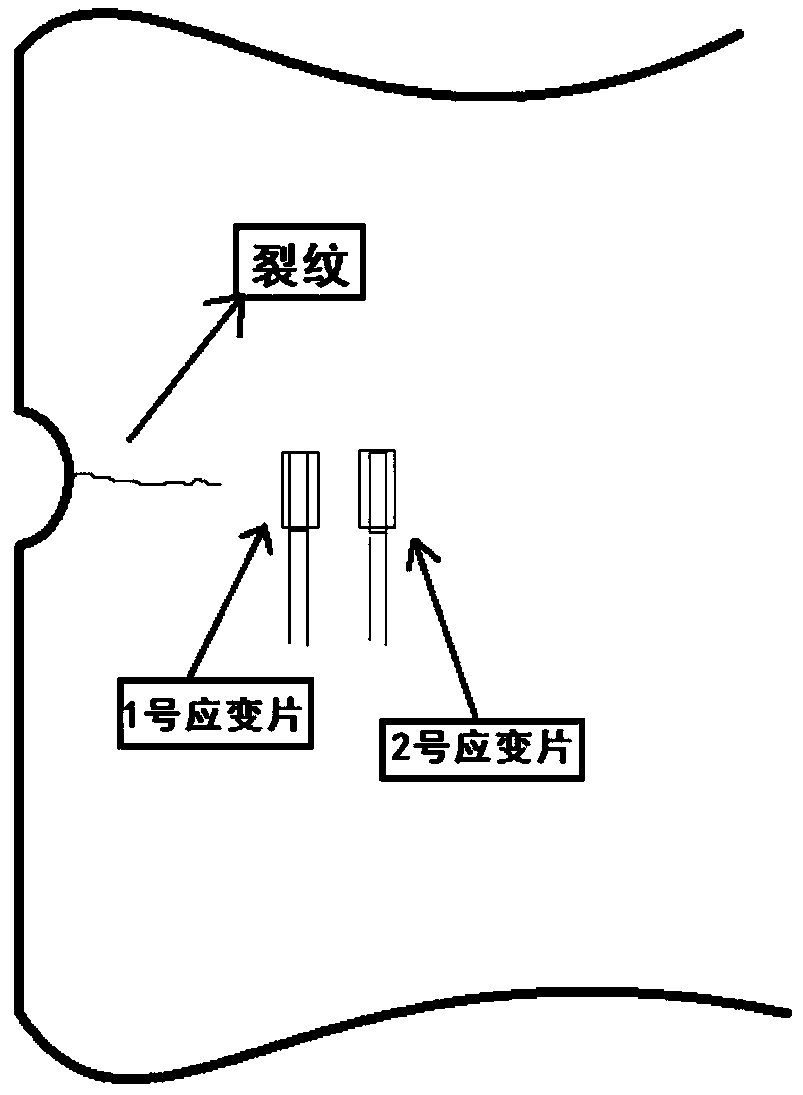

[0033] Step 1): Measure the crack length a, attach No. 1 and No. 2 strain gauges to the tip of the crack, make the measured strain direction perpendicular to the crack, and ensure that the connection of the two strain gauges is on the extension line of the crack, record No. 1 and No. 2 The distance between No. 2 strain gauge and the crack tip is r 1 and r 2 , and let r 1 and r 2 greater than 0.1 times the crack length a;

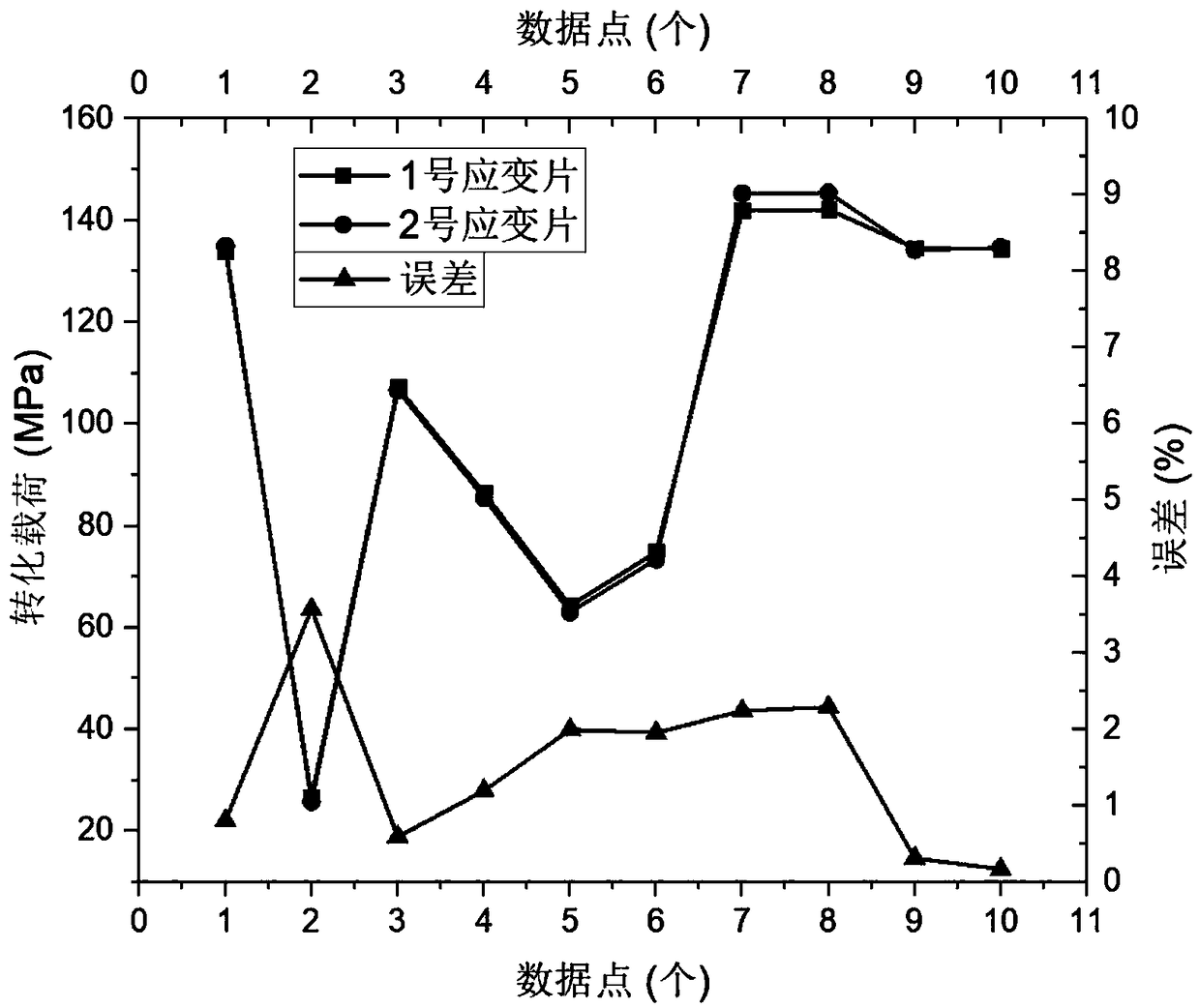

[0034] Step 2): Record the strain values measured by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com