Method for determining constitutive parameters of butt welded pipe welding seam in biaxial stress state

A bidirectional stress, straight seam welded pipe technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of inability to obtain the constitutive parameters of welded pipe welds

Active Publication Date: 2011-04-06

NORTHWESTERN POLYTECHNICAL UNIV

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

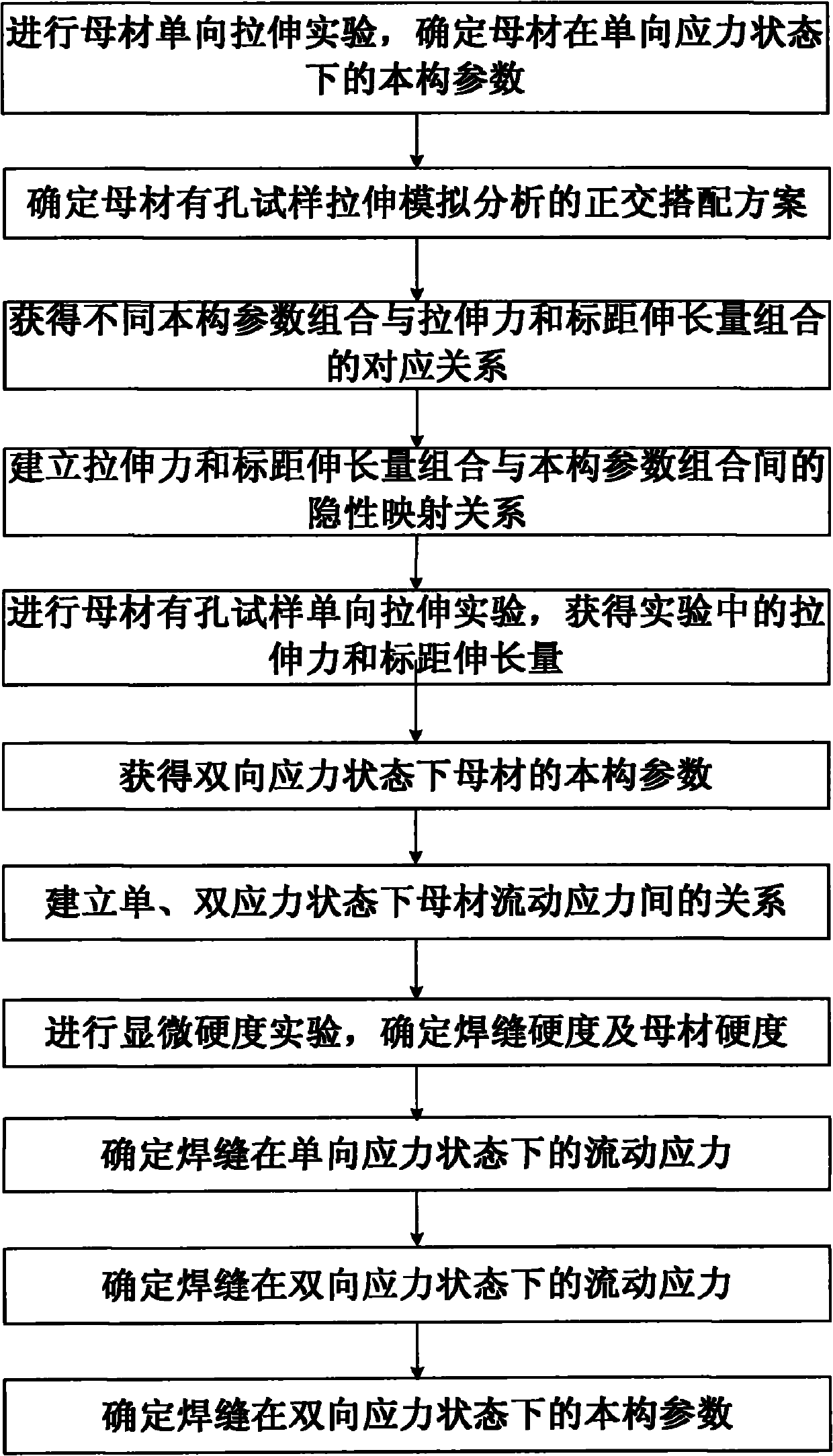

[0006] In order to overcome the problem that the existing technology cannot obtain the constitutive parameters of welded pipe welds under the state of bidirectional stress, the present invention proposes a method for determining the constitutive parameters of welded seams of straight seam welded pipes under the state of bidirectional stress

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

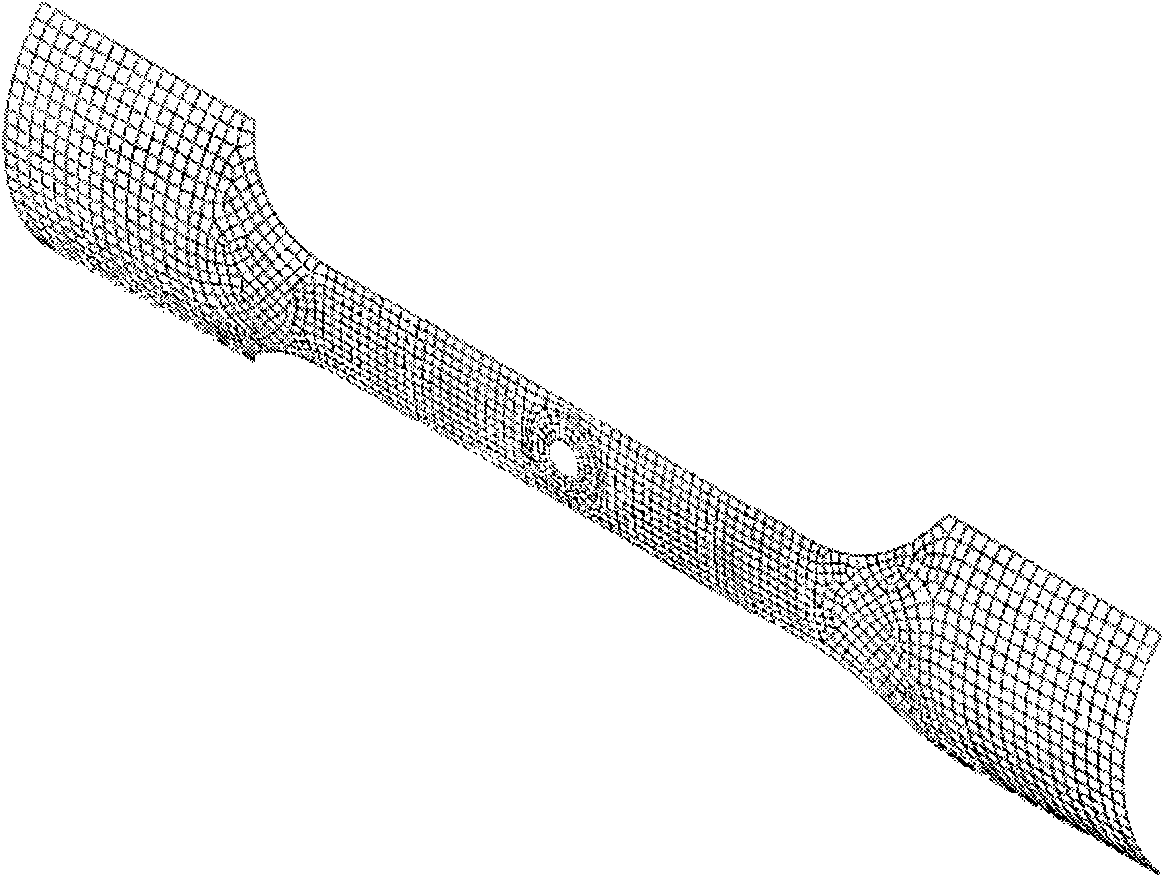

[0050] This embodiment is to determine the weld seam constitutive parameters of the QSTE340 two-way stress state with a specification of 78×2.7mm. The specific determination steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| strength coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a method for determining constitutive parameters of a butt welded pipe welding seam in the biaxial stress state, which comprises the following steps of: determining the constitutive parameters of the parent metal in the uniaxial stress state, thereby determining the range of the parent metal strength factor K<sim> in the perforated sample tensile finite element analogy, and the range of the hardening index n<sim>; and by determining the variation ranges of the strength factor and the hardening index, obtaining the relationship between different constitutive parameter combinations (K<sim>, n<sim>) and the combinations (F<sim>, Delta l<sim>) of tensile force and gauge length elongation, and establishing a recessive mapping relationship between the combination (F, Delta l) of tensile force and gauge length elongation and the constitutive parameter combination (K, n), thereby obtaining the constitutive parameters of the welding seam in the biaxial stress state. The method induces the planar biaxial tension stress state, which is more approximate to the true stress state of pipe deformation, in the uniaxial tension process of a perforated sample, can be used for accurately and efficiently determining the constitutive parameters of the welding seam ductility of a butt welded pipe, and is beneficial to enhancing the forming quality and the forming limit of the welded pipe.

Description

technical field [0001] The invention relates to the field of plastic forming of straight seam welded pipes, in particular to a method for determining the constitutive parameters of the weld seams of the straight seam welded pipes under the bidirectional stress state, and the technology can also be extended to the determination of the constitutive parameters of the weld seams of tailor welded blanks. Background technique [0002] Due to the characteristics of low cost, short cycle time and toughness, the bending parts of longitudinal welded pipes have been widely used in the automobile industry. The main difference between the welded pipe and the seamless pipe lies in the significant difference between the properties of the weld and the base metal, and the influence on the plastic forming performance is mainly reflected in the significant difference between the strength coefficient K and the hardening index n in the constitutive parameters of the weld and the base metal. The ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

Inventor 詹梅杨合刘静

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com