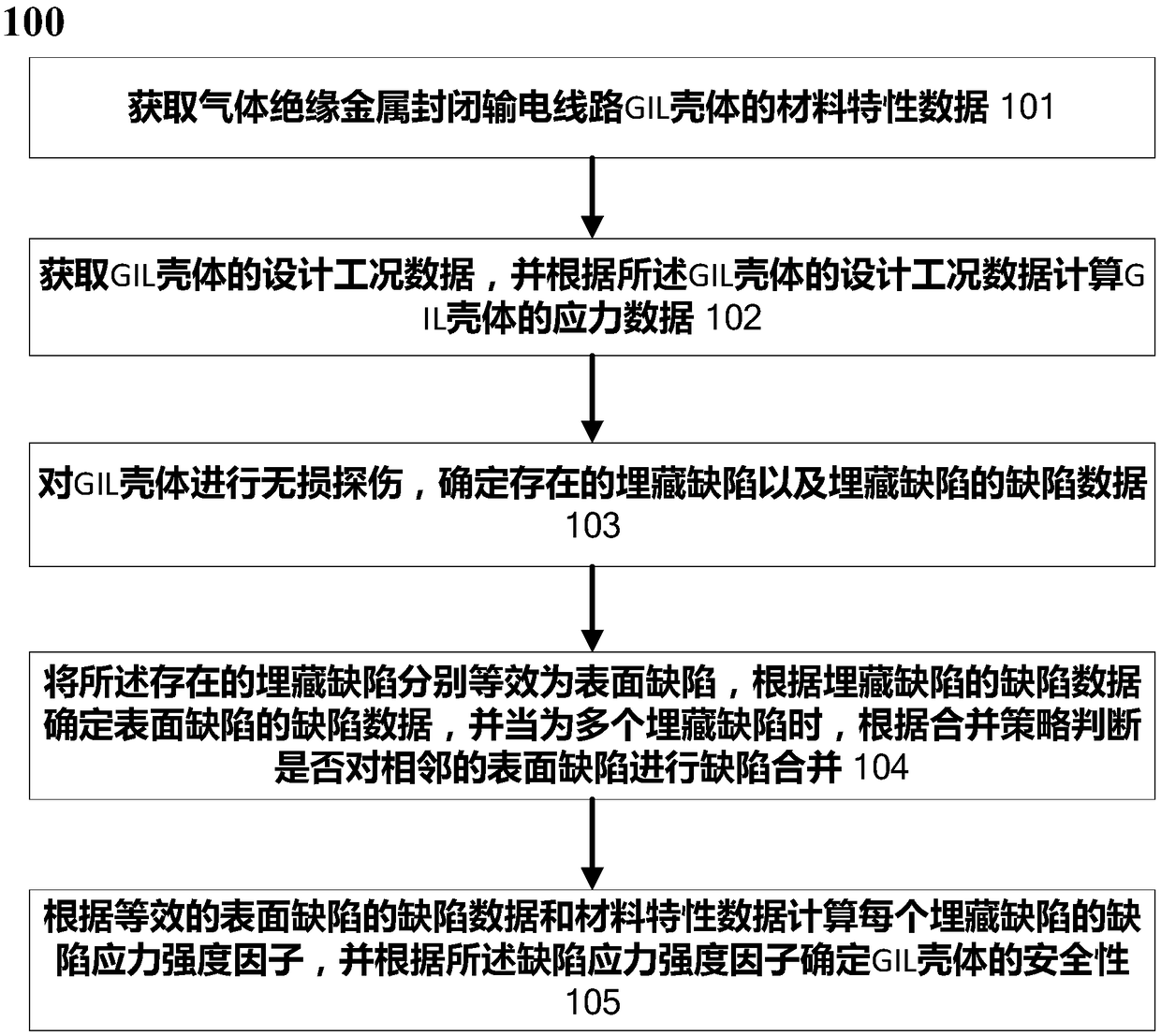

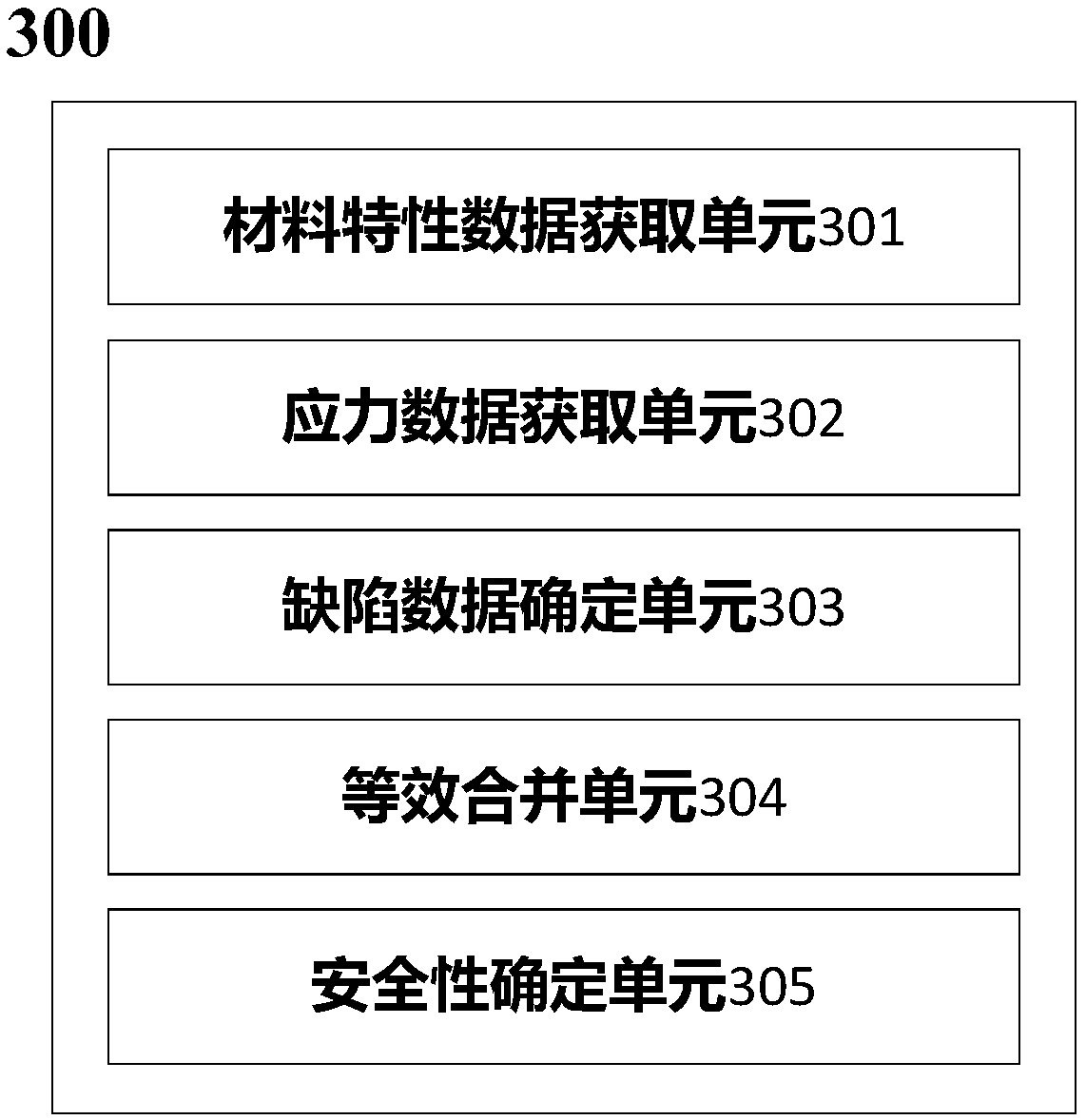

Method for determining safety of GIL shell containing buried defects and system thereof

A safety and defect technology, applied in the field of GIL shell safety, can solve problems such as GIL shell safety and remaining life evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

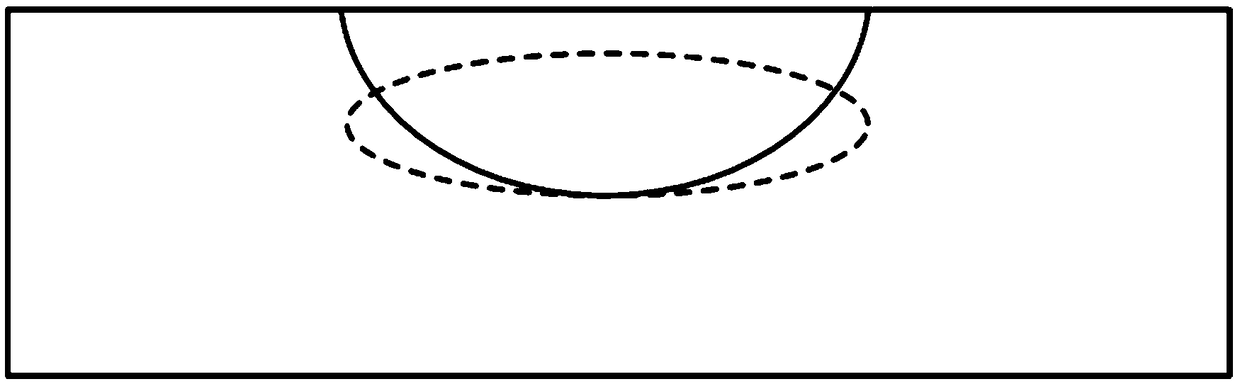

[0147] A UHV GIL shell is made of 5754 aluminum alloy, and there are two buried cracks inside the weld seam of the conventional non-destructive testing body:

[0148] Crack 1: The crack depth is a 1 = 3mm; the crack length is 2c 1 =8mm; 2mm from the outer surface of the shell;

[0149] Crack 2: The crack depth is a 2 =2.5mm; the crack length is 2c 2 =9mm; 3mm from the outer surface of the shell;

[0150] The distance between two cracks is s=6mm;

[0151] (1) Acquisition of material properties

[0152] The same batch of 5754 aluminum alloy was used for tensile, fracture toughness and fatigue performance tests to obtain the properties of the material, as follows:

[0153] GIL shell specification: 1160*16mm.

[0154] The service condition of GIL bears 0.6MPa.

[0155] Material yield strength: 150MPa; tensile strength: 240MPa

[0156] Fracture toughness: K IC =50MPa√m

[0157] Fatigue crack growth performance: da / dN=4.34×10 -5 (ΔK) 1.2 mm / cycle

[0158] (2) GIL Shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com