Crack-substrate coupling flow damage evaluating device and method by simulating formation conditions

A technology for simulating strata and evaluating devices, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc. It can solve the problem that engineering application does not have much reference value, and it is impossible to truly simulate the secondary stress around the well and the radial flow of the stratum, etc. problem, to achieve the experimental results and data real and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

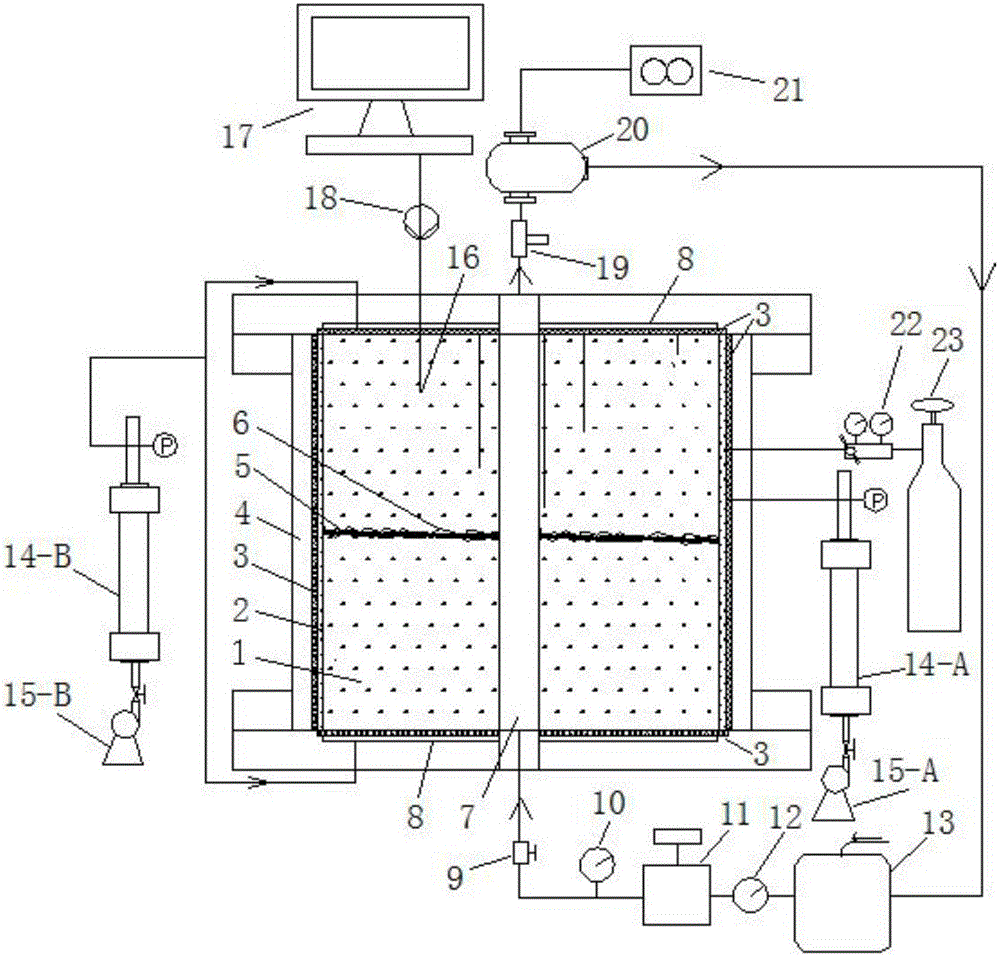

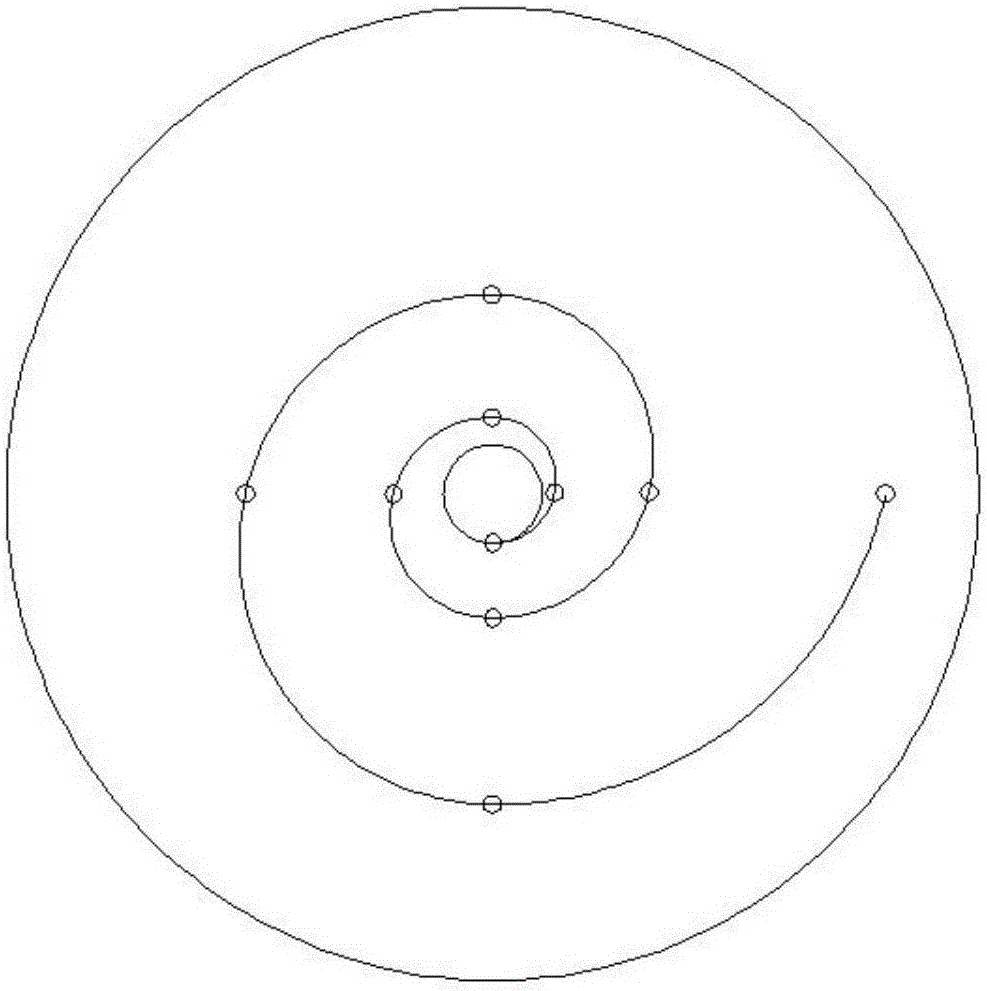

[0032] see figure 1 , figure 2 .

[0033] Fracture-matrix coupling flow damage evaluation device for simulating formation conditions, consisting of kettle body 4, rock core 1, fracture 6, simulated wellbore 7, pressurized capsule 3, electro-hydraulic cylinder one 14-A, electro-hydraulic cylinder two 14-B, Electric hydraulic pump one 15-A, electric hydraulic pump two 15-B, gas cylinder 23, resistance probe 16, pressure sensor 18, data acquisition system 17, and working fluid circulation system.

[0034] A rock core 1 is housed in the kettle body 4, and a pressurized capsule 3 is wrapped around the rock core 1. There is a cavity 8 between the pressurized capsule 3 and the kettle body 4. There are an axial pressure injection port, a confining pressure injection port and an air inlet on the kettle body. , the axial pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com