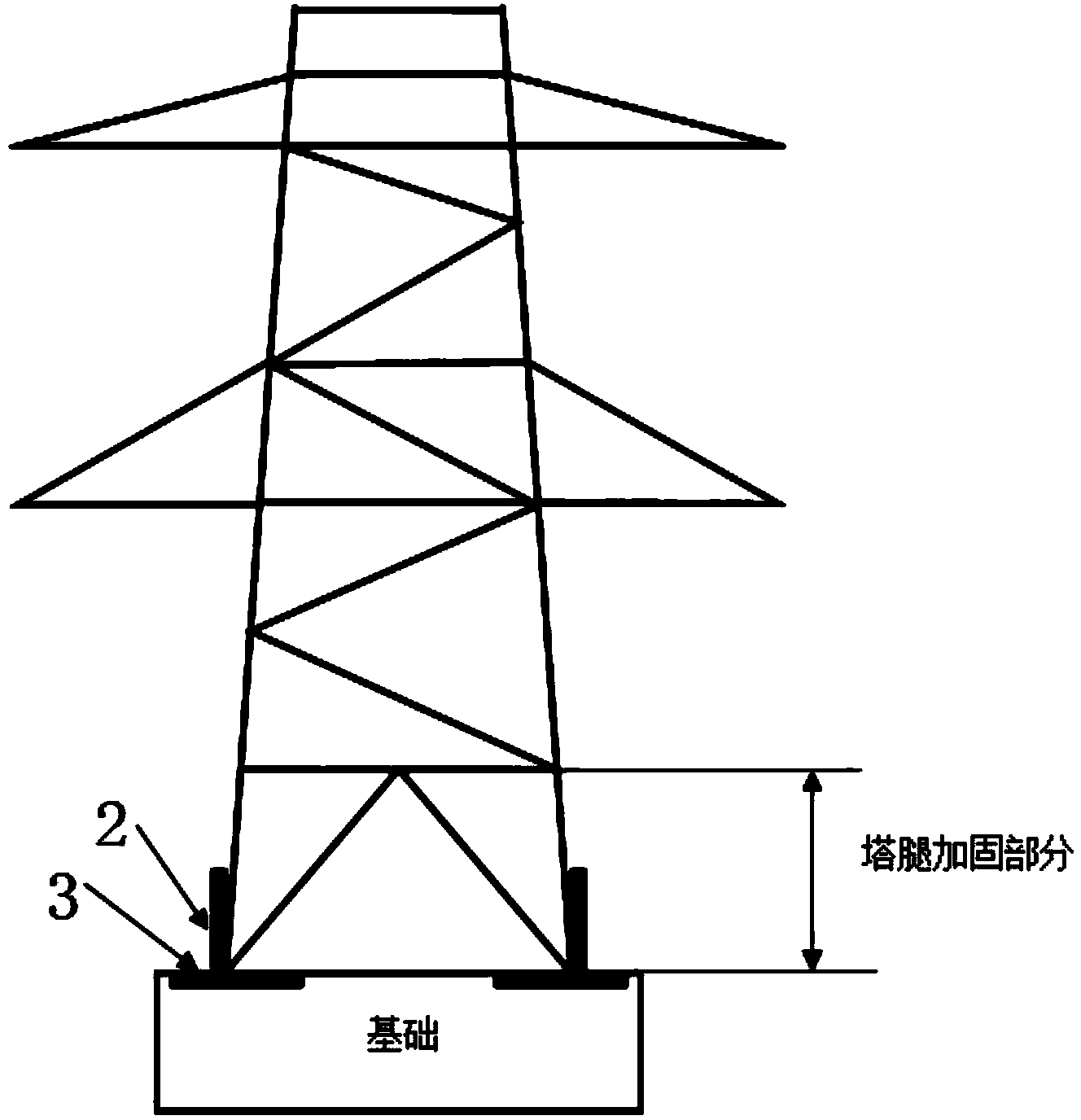

Method for field welding and strengthening of power transmission line steel angle tower leg

A technology for transmission lines and on-site welding, applied in welding equipment, towers, metal processing equipment, etc., can solve problems such as the adverse effect of the overall force on the tower, the difficulty of reinforcement, and the large number of bolts, so as to avoid the phenomenon of secondary force and avoid The effect of reducing the strength of hidden dangers and improving the safety of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

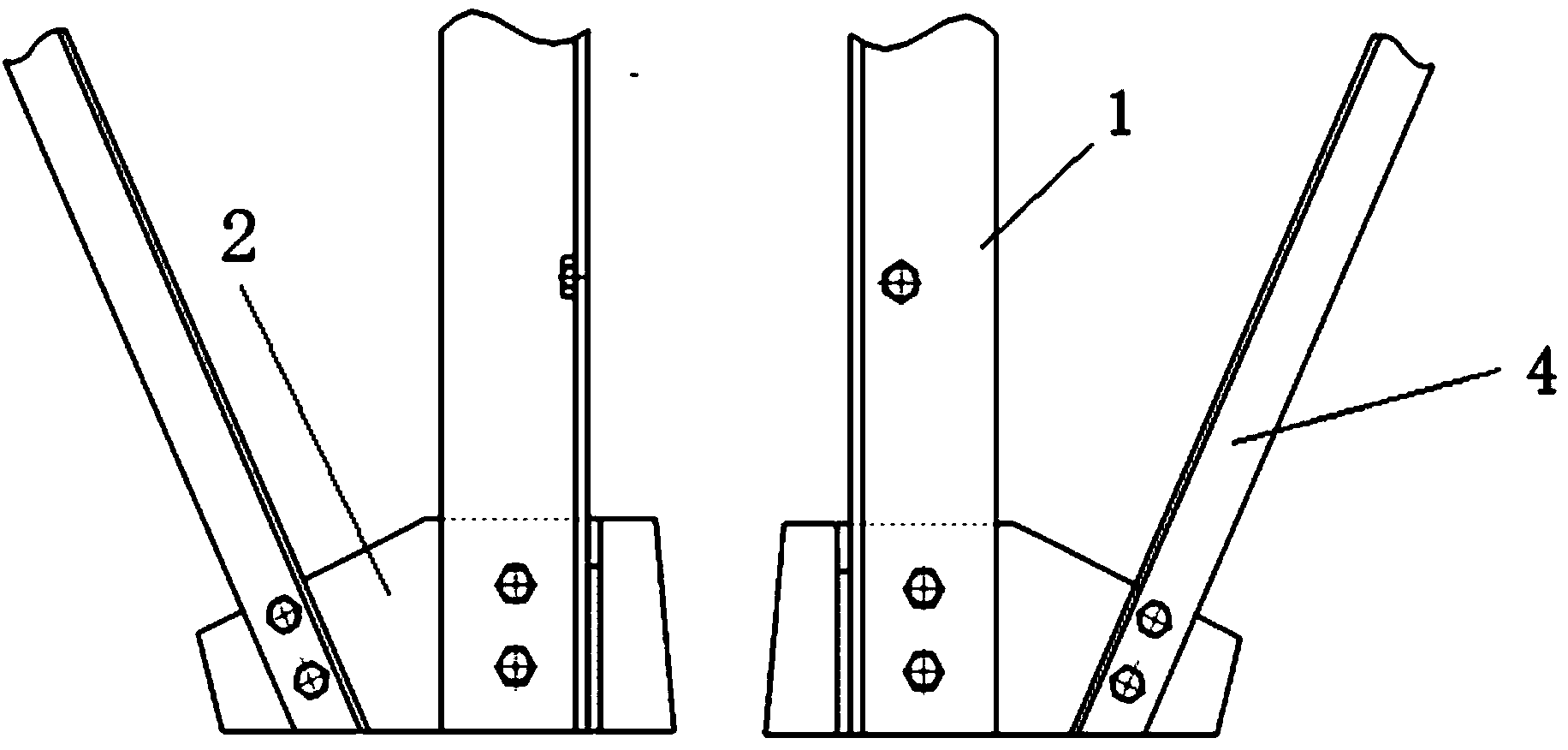

Embodiment 1

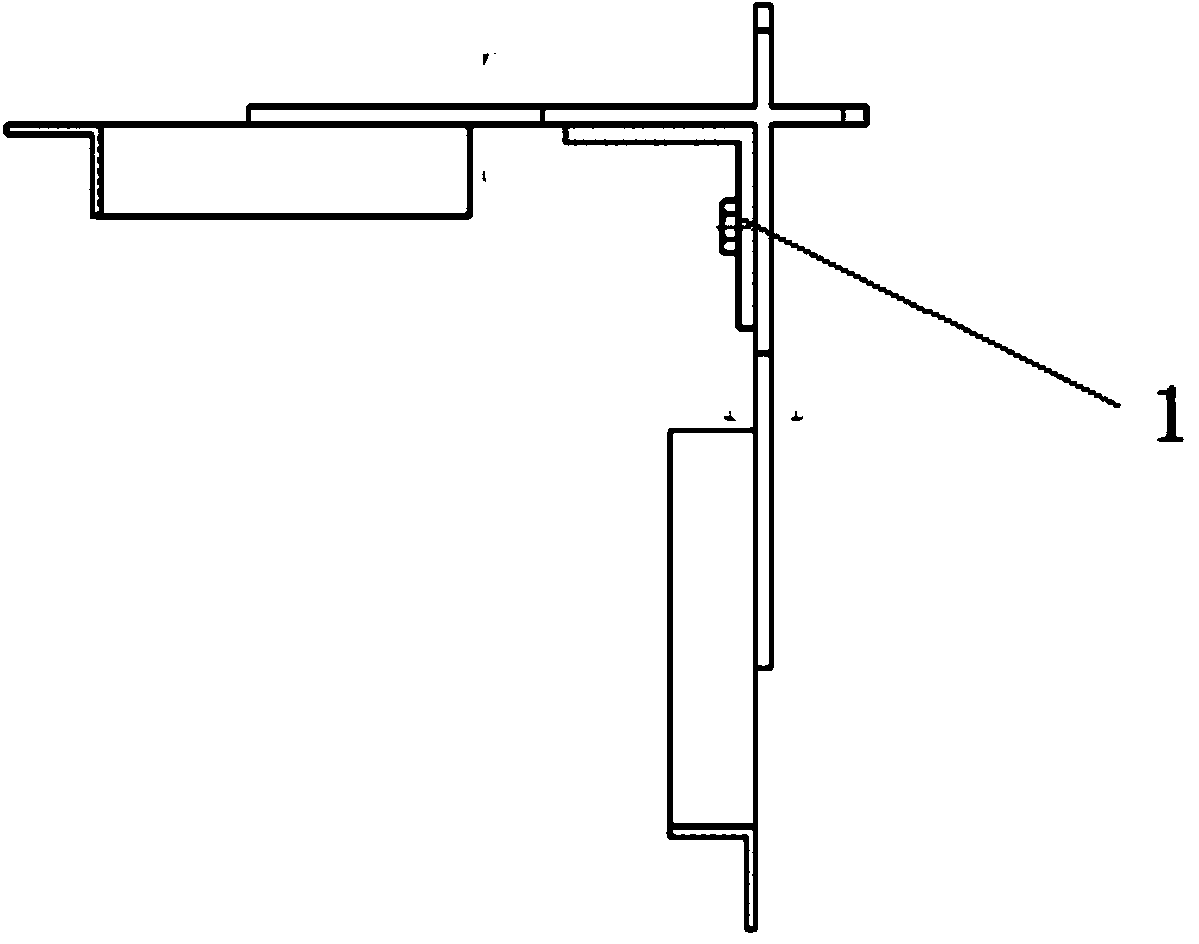

[0074] 1. According to the main material of the original tower leg, 1 size specification, select the size of the angle steel to be reinforced. The angle steel I5 and II7 selected in the size of the original tower leg main material 1 angle steel are respectively wider than the original angle steel tower leg main material angle steel side width b 6, 7mm thicker, reinforced angle steel I5 and reinforced angle steel II7 are 4, 5mm thicker than the main material angle steel edge of the original angle steel tower leg.

[0075] 2. During the reinforcement process, the connection between the reinforcement and the original angle steel tower parts is selected by welding method, the welding method is manual electrode arc welding, and the welding material is recommended to use E4303 type electrode.

[0076] 3. Welding current selection: 2.5mm diameter electrode is used, and the welding current is 60A-100A;

[0077] 4. The size of the fillet weld of the reinforcement is 3mm-8mm.

[0078] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com