Secondary stress loading test device convenient for reinforcing structure under constant load and manufacturing method of secondary stress loading test device

A technology of loading test device and secondary force, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Inexpensive and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

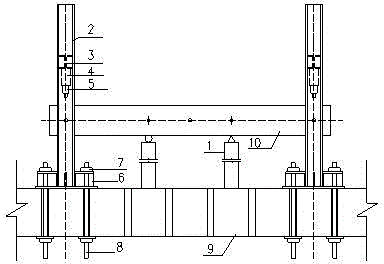

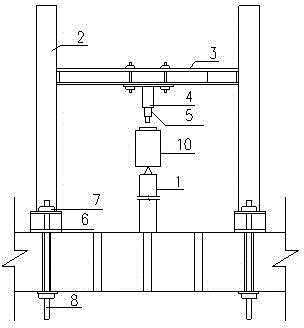

[0026] like Figure 1-5 As shown, a secondary force loading test device that is convenient for structural load reinforcement includes a base 1 that is fixedly connected to a rigid ground 9, and both sides of the base 1 are provided with load-bearing frames 2, and the load-bearing The lower part of the frame 2 is provided with a support 6, and the support 6 is fixedly connected with the rigid ground 9, and the support frame 2 is provided with a crossbeam 3 parallel to the rigid ground 9, and a jack 4 is hung upside down on the crossbeam 3, so that The jack 4 is perpendicular to the rigid ground 9 , a force sensor 5 is arranged on the jack 4 , and a test beam 10 is arranged between the jack 4 and the base 1 , and the test beam 10 is hinged to the jack 4 and the base 1 .

[0027] In this embodiment, the specific connection method between the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com