Secondary stress isolation structure applied to MEMS force sensitive device

A stress isolation and sensitive structure technology, applied in the direction of microstructure devices composed of deformable components, microstructure technology, microstructure devices, etc., can solve the problems of stress insensitivity, non-negligible, thermal characteristics mismatch, etc., to achieve The structure and process are simple, the stress isolation is comprehensive, and the effect of reducing stress sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

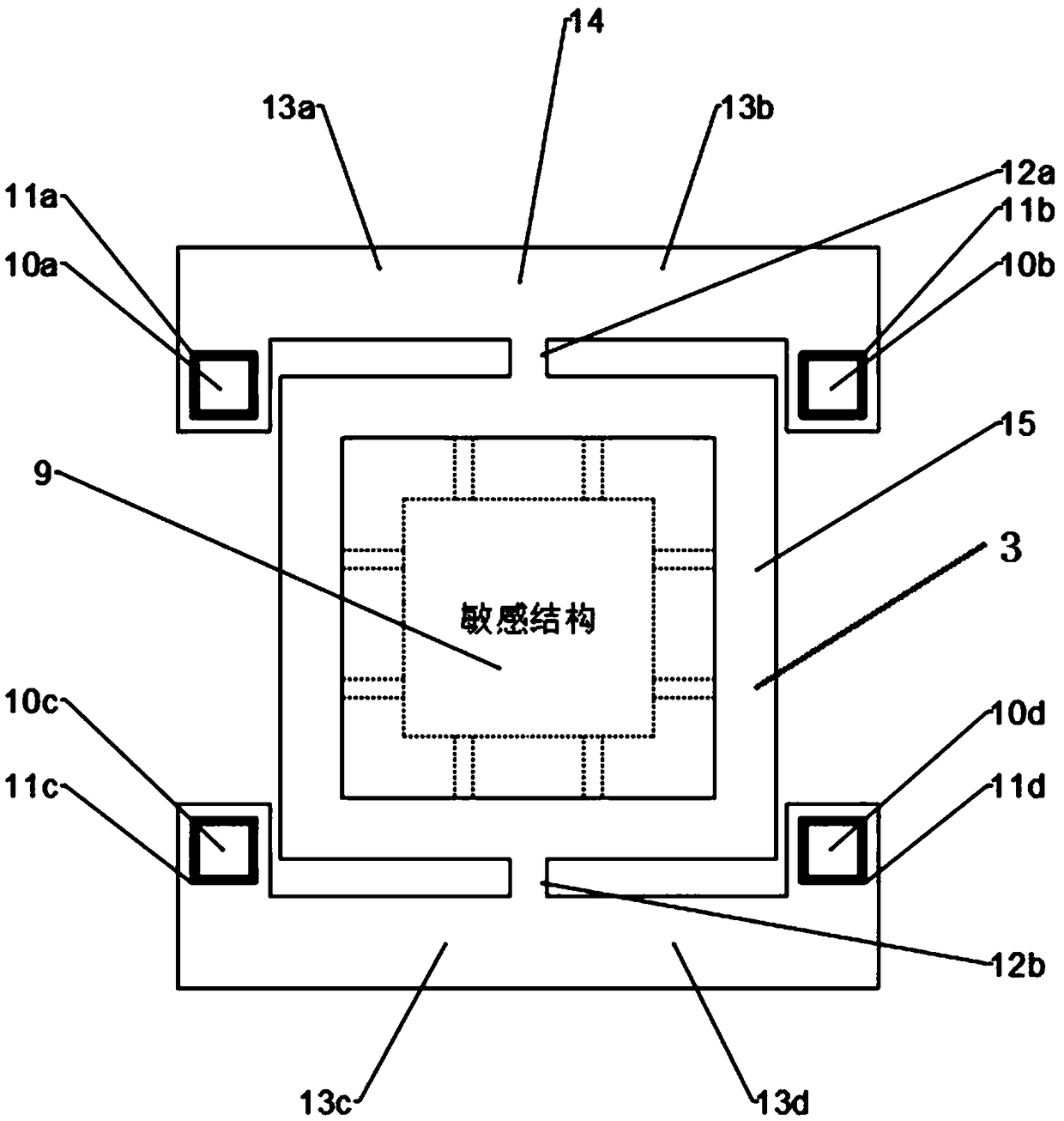

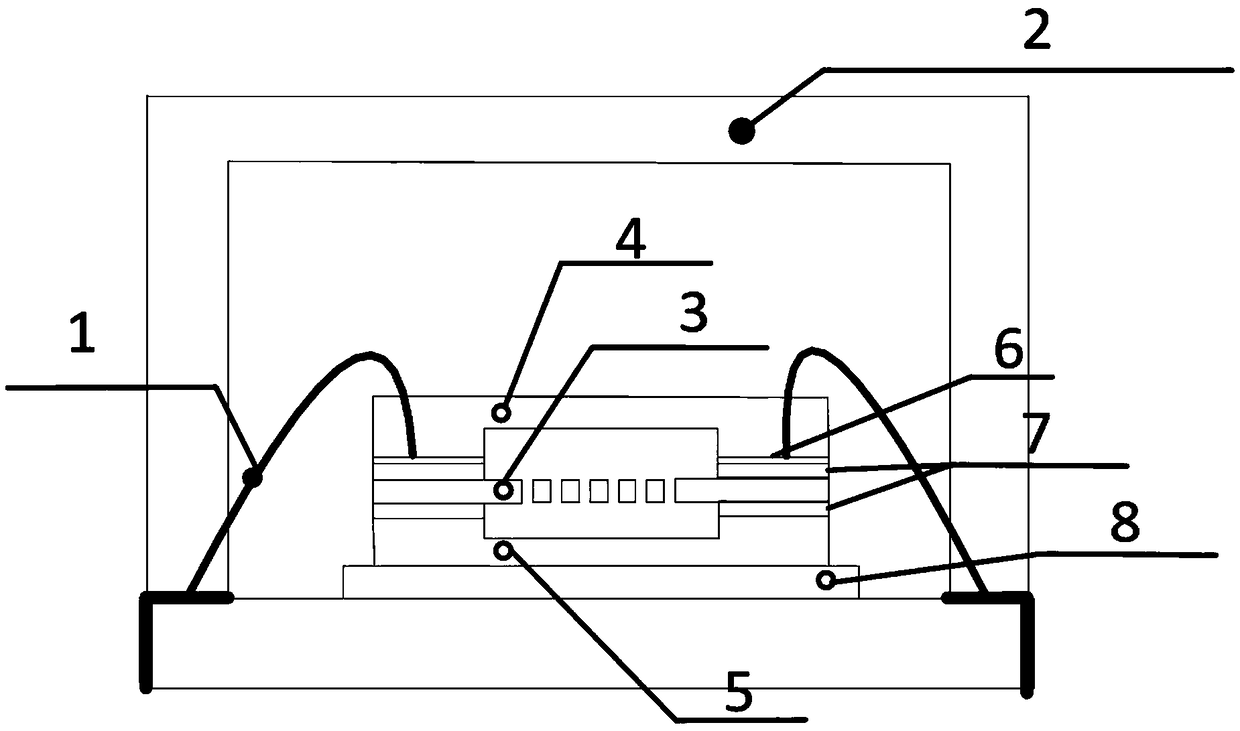

[0018] Such as figure 1 As shown, a secondary stress isolation structure 3 applied to MEMS force-sensitive devices includes an external frame structure 14 and a force-sensitive structure 9 arranged in the external frame structure 14, and the external frame structure 14 includes an internal frame 15, so The upper and lower ends of the inner frame 15 are respectively connected to the corresponding stress attenuation beam 13 through at least one stress concentration beam 12 , and the stress attenuation beam 13 is connected to the fixed anchor point 10 inside the flexible connection 11 through a plurality of flexible connections 11 .

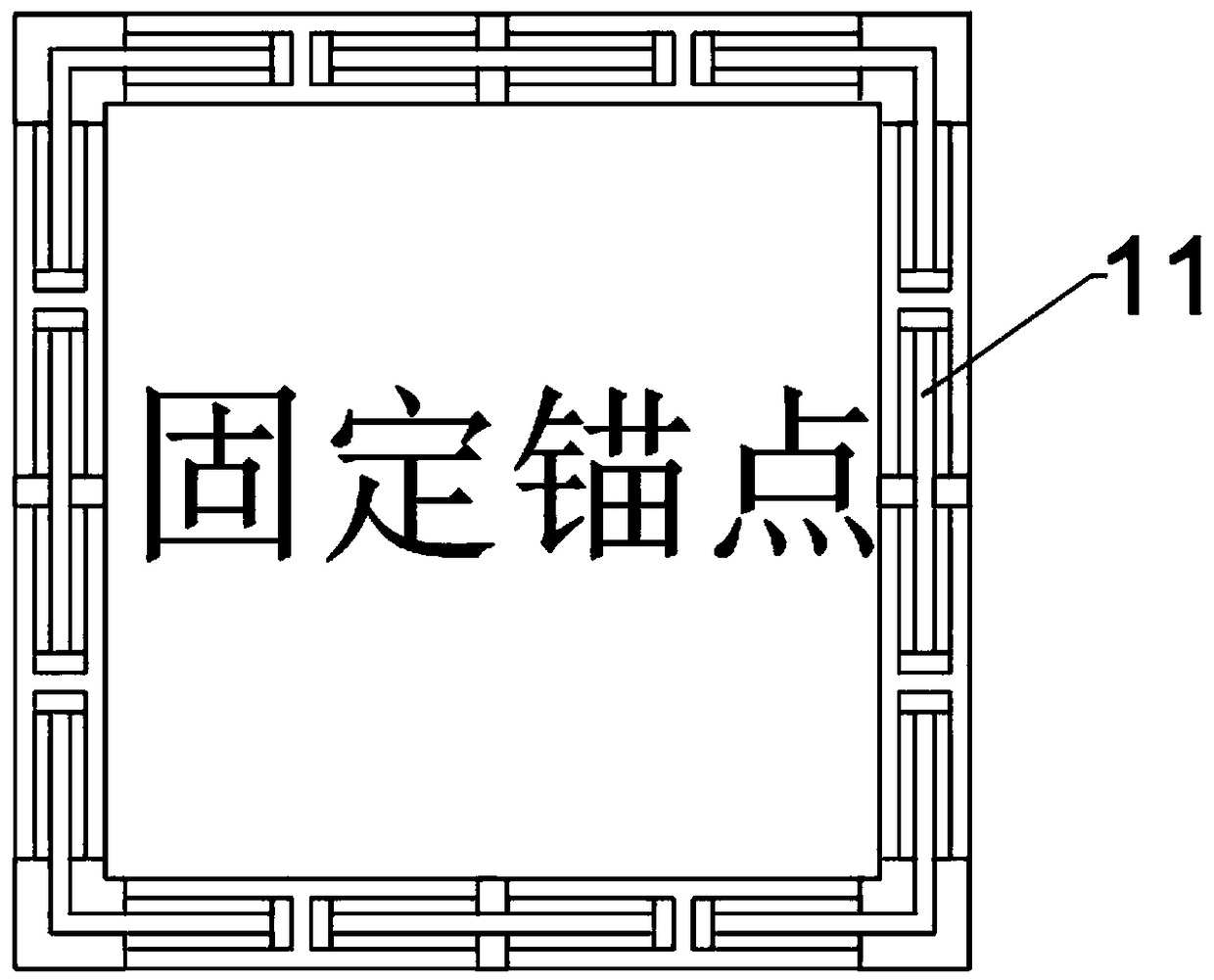

[0019] Further, the flexible connection 11 is composed of a U-shaped beam or an arched beam, such as figure 2 The flexible link 11 shown is formed by a U-shaped beam.

[0020] Further, the upper end of the inner frame 15 is connected with the upper left stress attenuation beam 13a and the upper right stress attenuation beam 13b through the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com