Thermoplastic vulcanizate compression stress relaxation reversible recovery behavior characterization method

A thermoplastic vulcanizate, compressive stress technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, instruments, etc., can solve problems such as qualitative and quantitative characterization methods that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

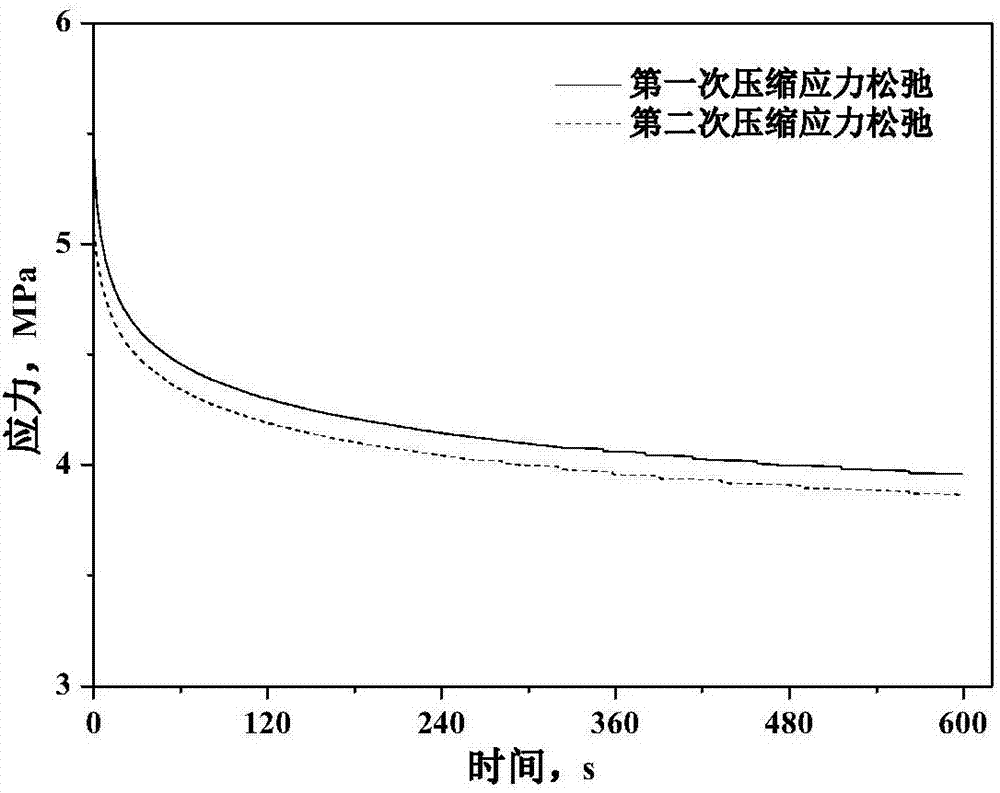

[0017] Example 1: Characterization of reversible recovery from compressive stress relaxation of EVA / NBR thermoplastic vulcanizates

[0018] Prepare cylindrical EVA (ethylene-vinyl acetate copolymer resin) / NBR (nitrile rubber) (mass ratio = 30 / 70) vulcanized rubber samples by molding method, and the samples should not have air bubbles, impurities and damage.

[0019] (1) Use GT-TCS-2000 electronic tensile machine to apply 50% strain on the cylindrical thermoplastic vulcanizate sample, and then test its stress relaxation behavior for the first time at room temperature. The test time is 10 minutes. height h 0 =9.86mm, when compressed to the specified compressive strain, the height is h s =4.93mm, record the stress-time relationship curve;

[0020] (2) After the first stress relaxation behavior test, the cylindrical sample was taken out from the universal testing machine, placed in a vacuum oven for heat treatment at 70°C for 30 minutes, and then taken out and cooled to room tem...

Embodiment 2

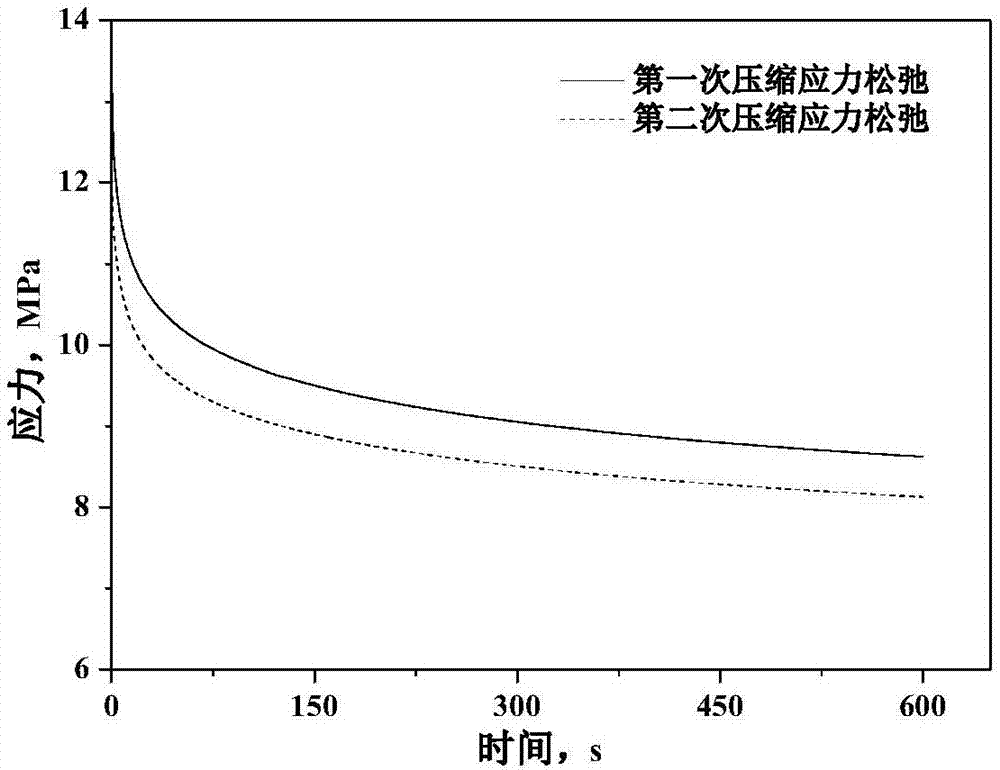

[0024] Example 2: Characterization of reversible recovery from compressive stress relaxation of PP / EPDM thermoplastic vulcanizates

[0025] Prepare cylindrical PP (polypropylene) / EPDM (ethylene propylene diene rubber) (mass ratio = 40 / 60) vulcanized rubber samples by molding method, and the samples should not have air bubbles, impurities and damage.

[0026] (1) Use GT-TCS-2000 electronic tensile machine to apply 50% strain on the cylindrical thermoplastic vulcanizate sample, and then test its stress relaxation behavior for the first time at room temperature. The test time is 10 minutes. height h 0 =9.99mm, when compressed to the specified compressive strain, the height is h s =4.995mm, record the stress-time relationship curve;

[0027] (2) After the first stress relaxation behavior test, the cylindrical sample was taken out from the universal testing machine, placed in a vacuum oven for heat treatment at 120°C for 30 minutes, and then taken out and cooled to room temperatu...

Embodiment 3

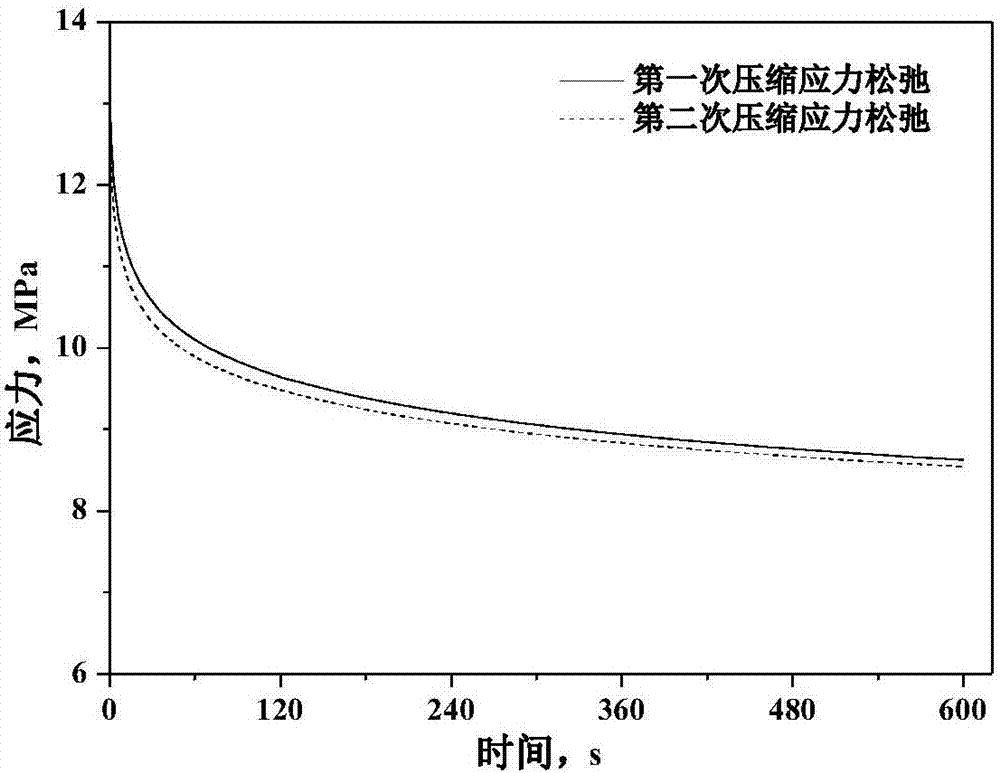

[0031] Example 3: Characterization of reversible recovery from compressive stress relaxation of PP / EPDM thermoplastic vulcanizates

[0032] Prepare cylindrical PP / DPDM (mass ratio = 40 / 60) vulcanized rubber samples by molding method, and the samples should not have air bubbles, impurities and damage.

[0033] (1) Use GT-TCS-2000 electronic tensile machine to apply 50% strain on the cylindrical thermoplastic vulcanizate sample, and then test its stress relaxation behavior for the first time at room temperature. The test time is 10 minutes. height h 0 =9.970mm, when compressed to the specified compressive strain, the height is h s =4.985mm, record the stress-time relationship curve;

[0034] (2) After the first stress relaxation behavior test, the cylindrical sample was taken out from the universal testing machine, placed in a vacuum oven for heat treatment at 140°C for 30 minutes, and then taken out and cooled to room temperature. At this time, the cylindrical sample height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com