Measuring method for real stress-strain curve of metal welding structure

A true stress-strain, metal welding technology, applied in the field of materials, can solve the problems of surface strain and deformation, the difficulty of stress-strain relationship, the inability to accurately measure the stress-strain curve, etc., to achieve the effect of ensuring uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

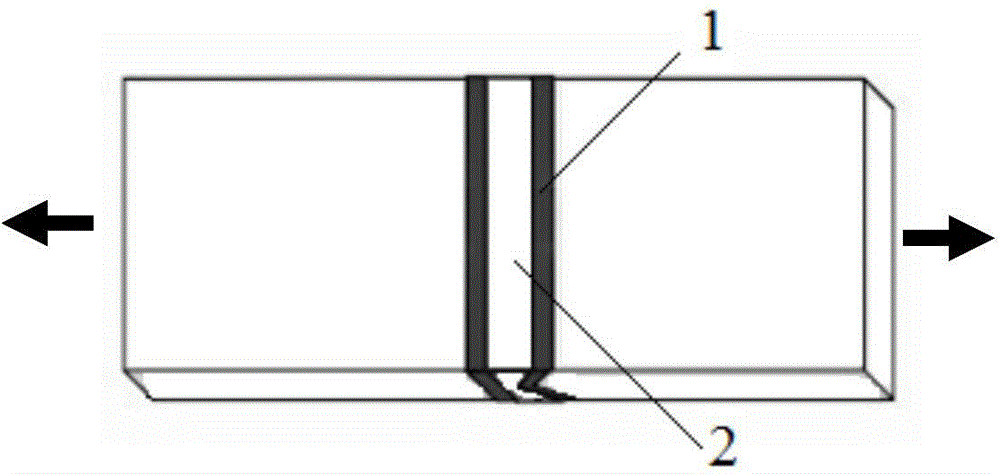

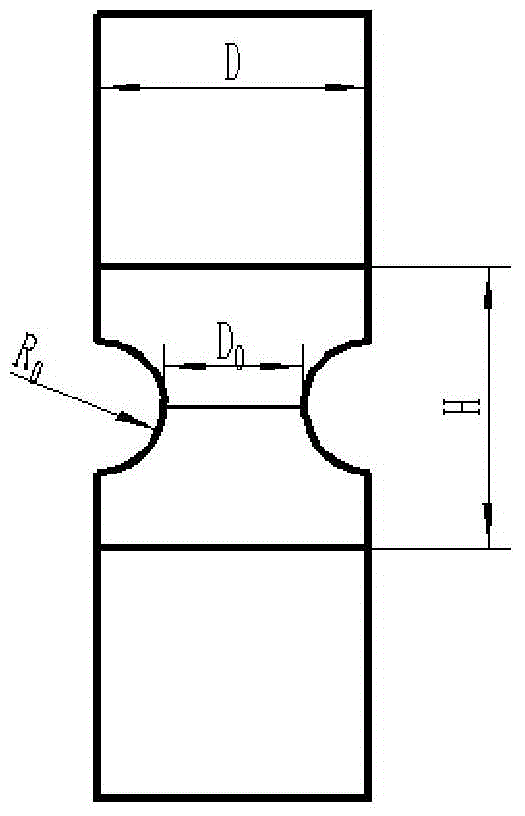

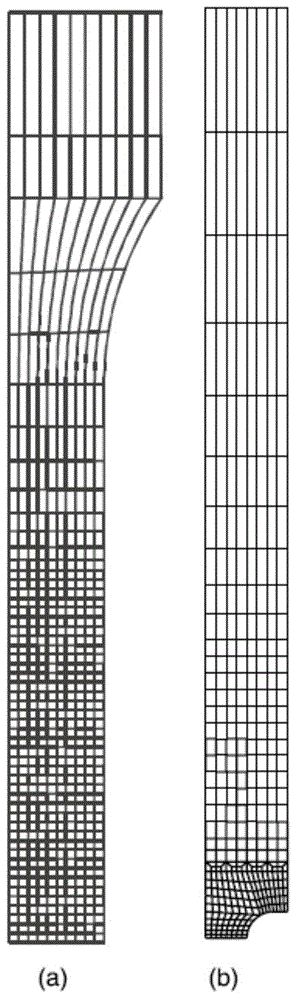

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings. In order to measure the real stress-strain curves of different material regions of the welded structure, the present invention mainly solves the difficult problem that it is difficult to accurately measure the real stress-strain curves of materials in different regions in the heterogeneous materials of the welded structure, and provides a weld metal or thermal The method for measuring the true stress and strain of metal materials in the affected zone includes the following steps:

[0048] (1) Test and measurement system:

[0049] Electronic tensile or hydraulic servo tensile testing machine is used, the load range is not less than 100KN, and it is equipped with measuring instruments and data recording systems that can record the tensile load position and real fracture strain.

[0050] (2) Preparation of notched tensile test samples:

[0051] Cut out a sample block wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com