Method for measuring volume distribution of retained austenite in transformation induced plasticity (TRIP) steel stamped part

A technology of residual austenite and measurement method, which is applied in the field of volume distribution measurement of retained austenite in steel stamping parts, can solve the problems of increasing additional process cost and measurement cost, unsuitable application, high measurement times and measurement cost, etc., to achieve Low time cost and economic cost, simple implementation and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for measuring volume distribution of retained austenite in TRIP steel stamping parts, comprising the following steps,

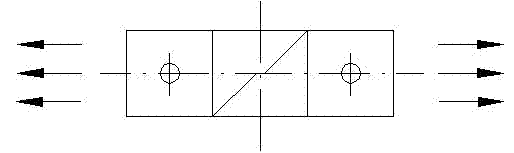

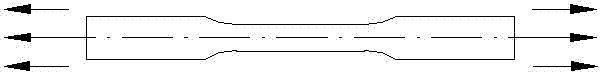

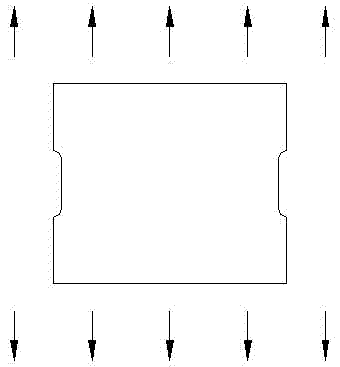

[0031] Step 1. Classify the deformation into four standard deformation modes, simple shear, uniaxial tension, plane strain tension and equal biaxial tension, and prepare corresponding simple shear specimens, uniaxial tensile specimens, Plane strain tensile specimens and biaxial tensile specimens;

[0032] Step 2. First use the existing X-ray diffraction method, neutron diffraction method, optical microscope combined with pixel analysis method, scanning electron microscope method or Mössbauer spectroscopy method to measure the volume content of retained austenite before deformation of the sample , and then the four samples were stretched on a universal stretching machine, and the principal strain was obtained by stretching , secondary variable , the thickness strain , to calculate the equivalent variable in four cases , and then use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com