Bearing reaction force detection method for I-shaped steel-concrete composite beam

A technology of I-shaped steel and detection methods, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve problems such as actual weight deviation of integrated bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

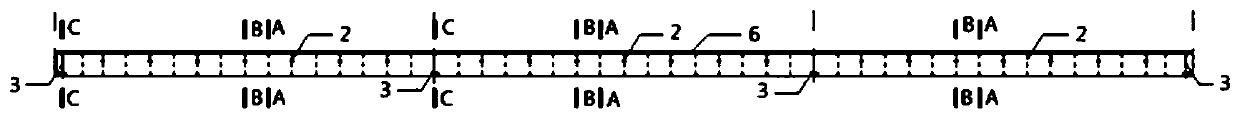

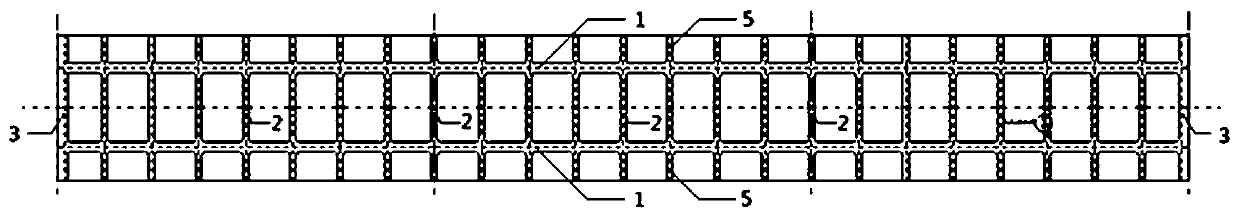

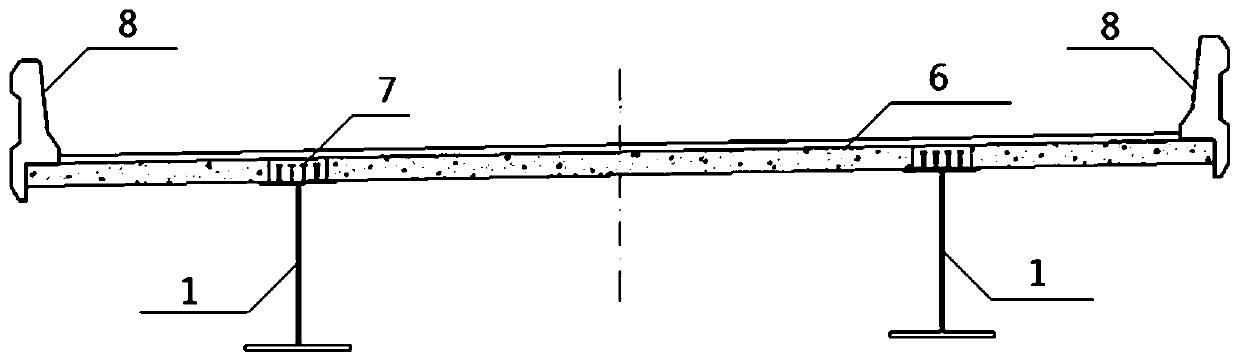

[0030] Figure 1~5 It is the overall elevation, plan and cross-sectional view of the three-span continuous composite beam. The composite beam is composed of a steel main beam, a concrete bridge deck 6, and shear nails 7. The steel main beam consists of two I-shaped main beams 1 and small and medium-span beams 2. The fulcrum beam 3 and the cantilever beam 5 are composed. The steel main beam is connected with the concrete bridge deck 6 through shear nails 7 to form a combined structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com