Anti-jamming single-shield TBM main machine structure and anti-jamming method thereof

A single-shield, anti-jamming machine technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as easy jamming of machines and affecting construction, so as to improve applicability, ensure construction quality, and slow down formation deformation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

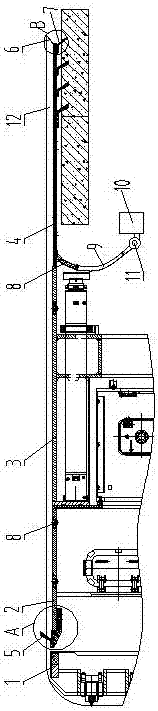

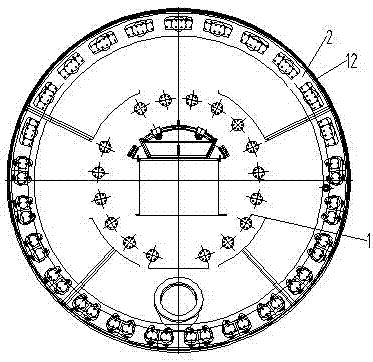

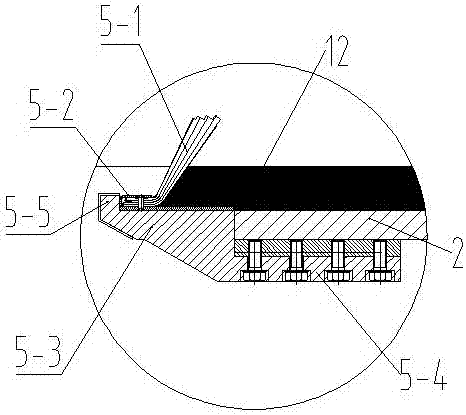

[0023] Such as Figure 1-4 As shown, a single-shield TBM host structure of an anti-jamming machine includes a cutter head 1, the cutter head 1 is connected with the shield body, the shield body includes a front shield 2, a middle shield 3 and a tail shield 4 in turn, and the front end of the front shield 2 It is connected with the cutter head 1, the rear end of the front shield 2 is connected with the front end of the middle shield 3, the rear end of the middle shield 3 is connected with the tail shield 4, and a front shield is detachably arranged on the shield wall at the front end of the front shield 2 The slurry stop brush 5 is provided with an upper tail brush 6 on the outer surface of the shield wall at the rear end of the tail shield 4, and the lower tail brush 7 is arranged on the shield wall inner surface of the tail shield 4 rear end, and the upper tail brush 6 and the front shield slurry stop brush 5 are arranged one by one Correspondingly, the corresponding upper ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com